Bottom casting system of strip sectional inner runners

A technology of gating system and inner runner, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of shrinkage cavity and shrinkage castings, scrapping, high sand-iron ratio, etc., and achieve small contact heat joints and reduce production The effect of low cost and low sand-iron ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below through a preferred embodiment in conjunction with the accompanying drawings.

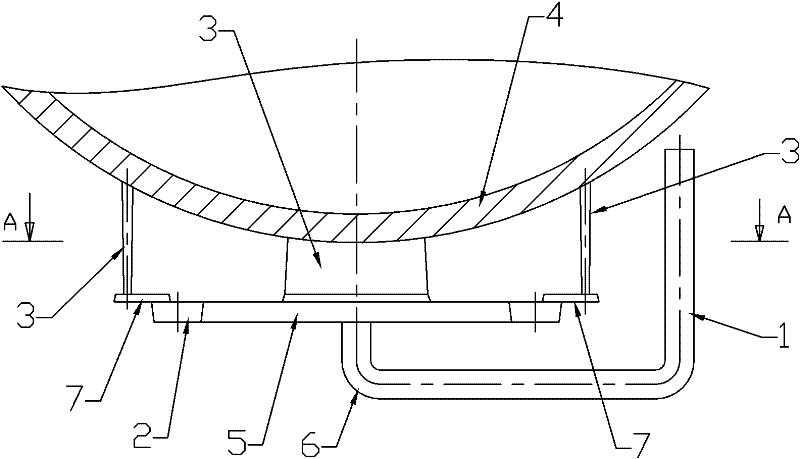

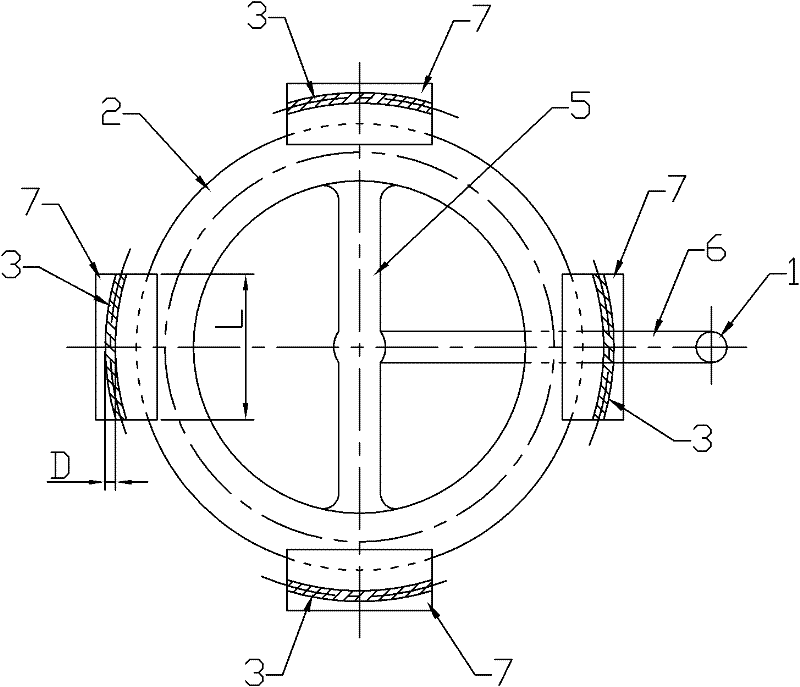

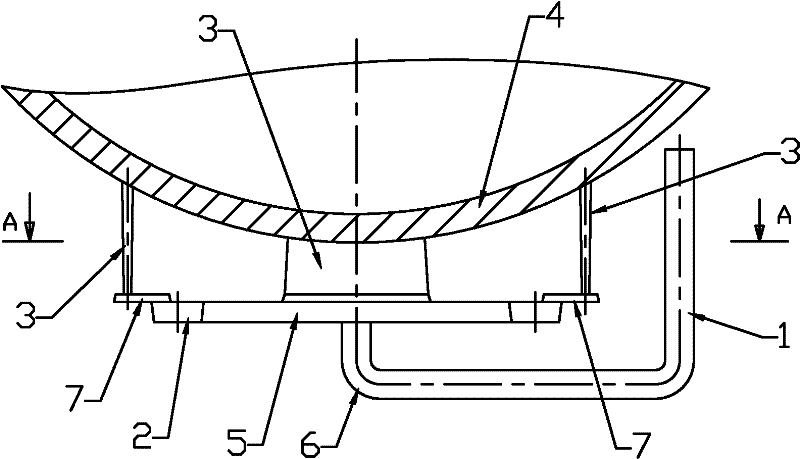

[0012] The bottom pouring type pouring system of the belt-shaped cross-section inner runner of the present invention, such as figure 1 , 2 As shown, it includes a connected sprue 1, a runner 2, at least two ingates 3, and a cavity 4. The runner 2 and the ingate 3 are located below the cavity 4, and the ingate 3 is in the form of The runner 2 is connected vertically and from the bottom of the cavity 4, and the inner runner 3 is made of molding sand to form a strip-shaped cross section. The strip-shaped cross-section refers to the fact that the length L of the cross-section is greater than the width D of the cross-section, especially the aspect ratio of the cross-section of the ingate (that is, the ratio of the length L of the cross-section to the width D of the cross-section) is 3 :1 to 12:1, during specific implementation, the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com