A sand-coated iron mold process for the production of driving wheel steel castings

A technology of sand-coating iron molds and steel castings, which is applied to the improvement of process efficiency, casting molds, and casting mold components. Effects of tensile strength, high impact toughness, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

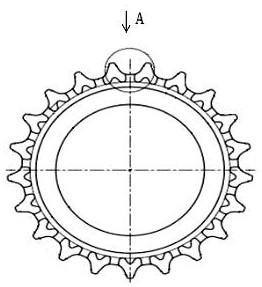

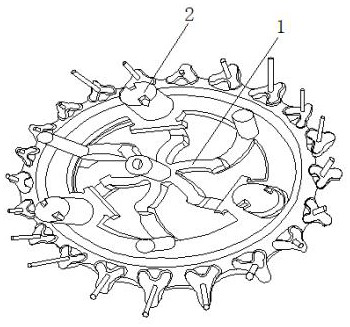

[0053] like Figure 1 to Figure 6 The iron mold sand-covering process shown for the production of driving wheel steel castings includes the following steps:

[0054] The first step, modeling,

[0055] 1) When molding, first place the sand box in the annealing furnace to preheat to 260°C, heat the mold to 180~220°C, and evenly open six inflow channels 1 of 40*40mm in * shape on the casting, and in Three heating risers 2 of Φ80*110mm are evenly arranged at the non-heating joints of the inner ring of the casting;

[0056] 2) After the mold and the sand box are tightly attached, the sand shooting is ready to start, the sand shooting pressure is adjusted to 0.55~0.6MPa, and the mold locking pressure is adjusted to 8~8.5MPa;

[0057] 3) Add 500kg of coated sand special for casting steel into the sand shooting bucket, and do a good job of screening, filtering and dust removal, and carry out the sand shooting operation. The gas volume is 80,000ml, the pouring time for each case is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com