Atmospheric pressure spherical sand riser bush and manufacturing method

A technology based on atmospheric pressure and manufacturing methods, applied in the field of riser sleeves, can solve the problems of reducing production costs and low feeding efficiency of open top risers, and achieve the effects of reducing machine loss rate, improving process yield, and saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

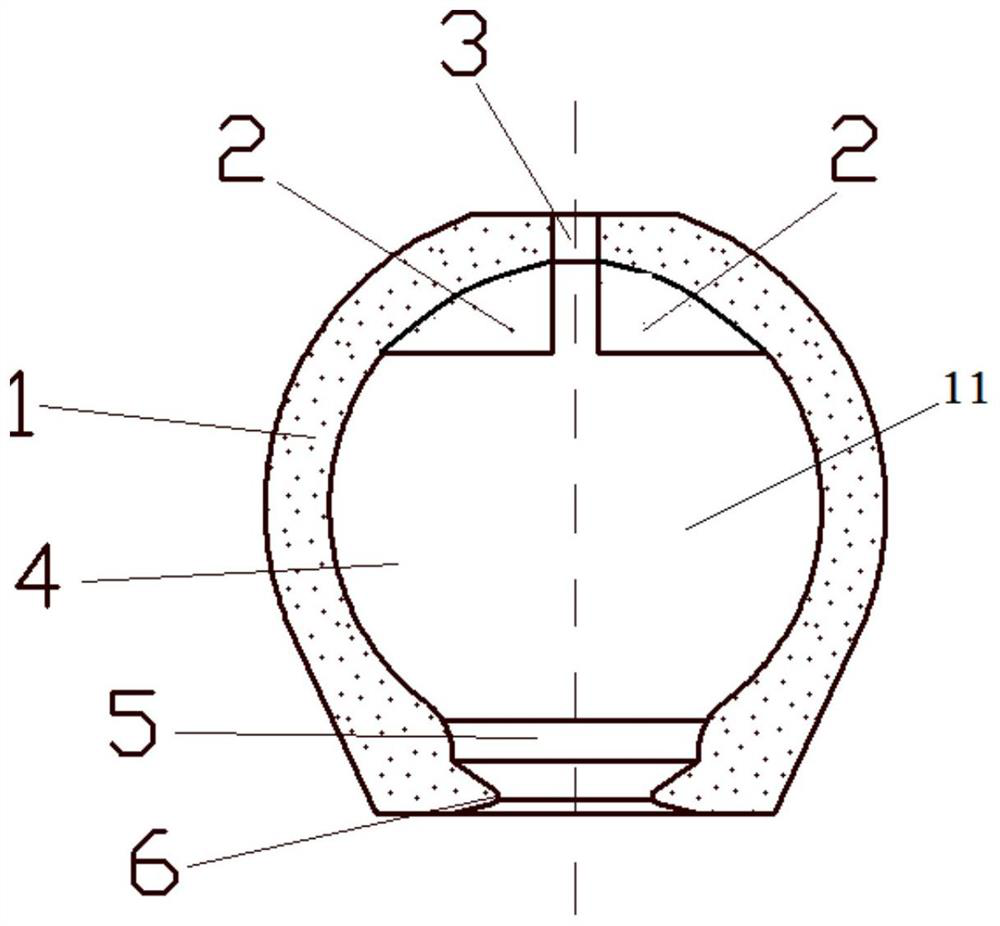

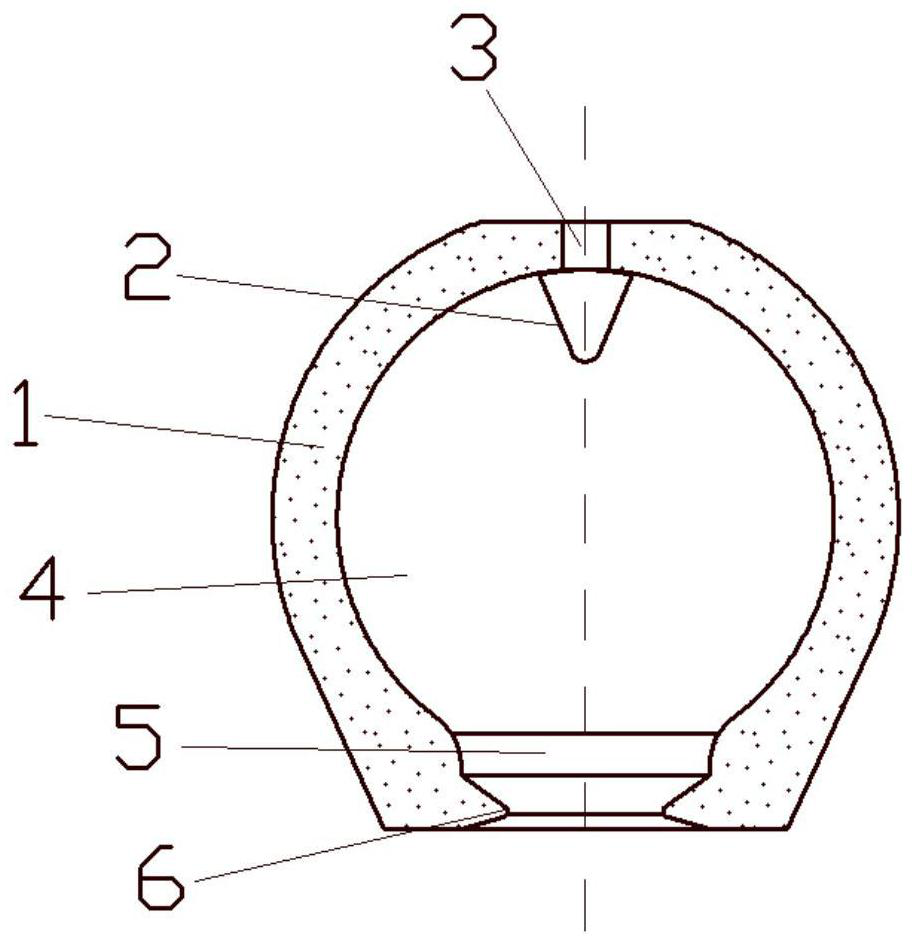

[0031] Such as Figure 1-Figure 2 , an atmospheric pressure spherical sand riser sleeve 1, including a riser body 4 and a pointed sand 2.

[0032] The main body of the atmospheric pressure spherical sand riser sleeve 1 is a riser body 4, and the riser body 4 has a spherical structure. For the geometry of the same volume, the specific surface area of the spherical shape is the smallest, the thermal modulus is the largest, the heat dissipation of the riser body is slow, and the feeding efficiency is high. For castings with the same volume, the amount of molten iron required for the spherical riser is the least.

[0033] An air outlet hole 3 is arranged at the middle position of the top of the riser body 4 . The air outlet hole 3 is a through cylindrical hole, the main function is to communicate with the atmosphere, cooperate with the peak sand 2 to form an atmospheric pressure riser, improve the feeding efficiency of the riser, and the air in the cavity and the riser can be r...

Embodiment 2

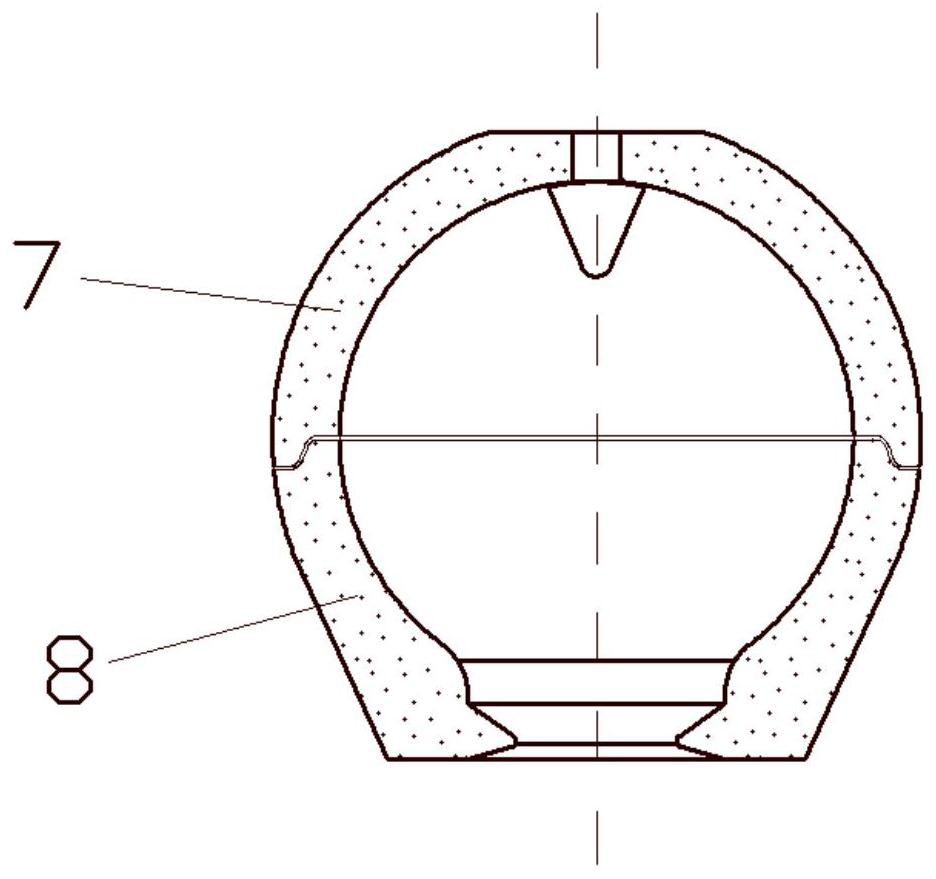

[0042] A kind of manufacture method of atmospheric pressure spherical sand riser sleeve, such as image 3 , the molding method of the atmospheric pressure spherical sand riser cover is that the upper and lower halves are respectively formed, and the horizontal maximum diameter of the riser body 4 is divided into types. The riser cover is composed of an upper riser cover 7 and a lower riser cover 8. The upper part The riser sleeve 7 and the lower riser sleeve 8 are provided with a buckle structure to cooperate to form an atmospheric pressure spherical riser. The riser sleeve can be realized by manual molding or core shooting machine, and two sets of molds are needed for molding.

Embodiment 3

[0044] A kind of manufacture method of atmospheric pressure spherical sand riser sleeve, such as Figure 4, the molding method of the atmospheric pressure spherical sand riser sleeve is that the left and right halves are respectively formed, and the vertical maximum diameter of the riser body 4 is divided into types, and the riser sleeve is composed of a left riser sleeve 9 and a right riser sleeve 10 , The left riser cover 9 and the right riser cover 10 are provided with a snap-in button structure to cooperate to form an atmospheric pressure spherical riser. The riser sleeve can be realized by hand molding or core shooting machine. Such as Figure 5 , the buckle structure 91 of the riser cover 9 is a protruding structure 1, the buckle structure 92 is a pit structure 1, the buckle structure 93 is a pit structure 2, and the buckle structure 94 is a protruding structure 2, wherein, The protruding structure 1 and the dimple structure 2 have the same shape and structure, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com