A kind of highly conductive graphene film and preparation method thereof

A graphene film, high conductivity technology, applied in chemical instruments and methods, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve problems such as difficult control, complex chemical reactions, etc. The process is simple and easy to implement, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

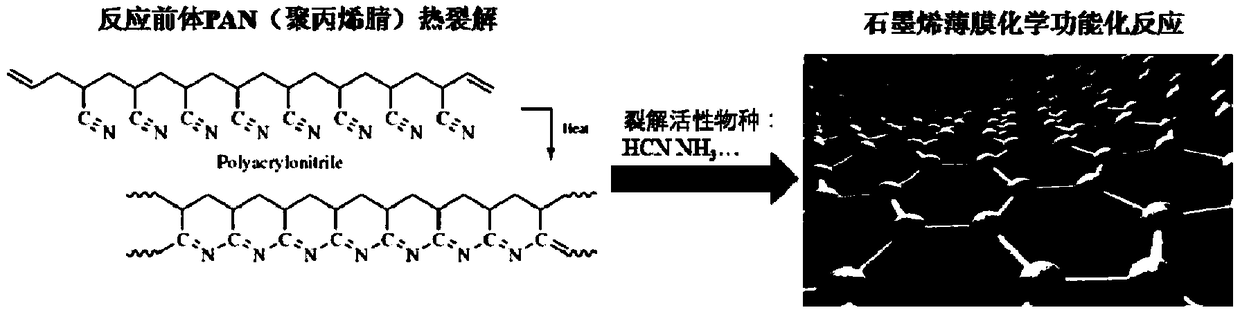

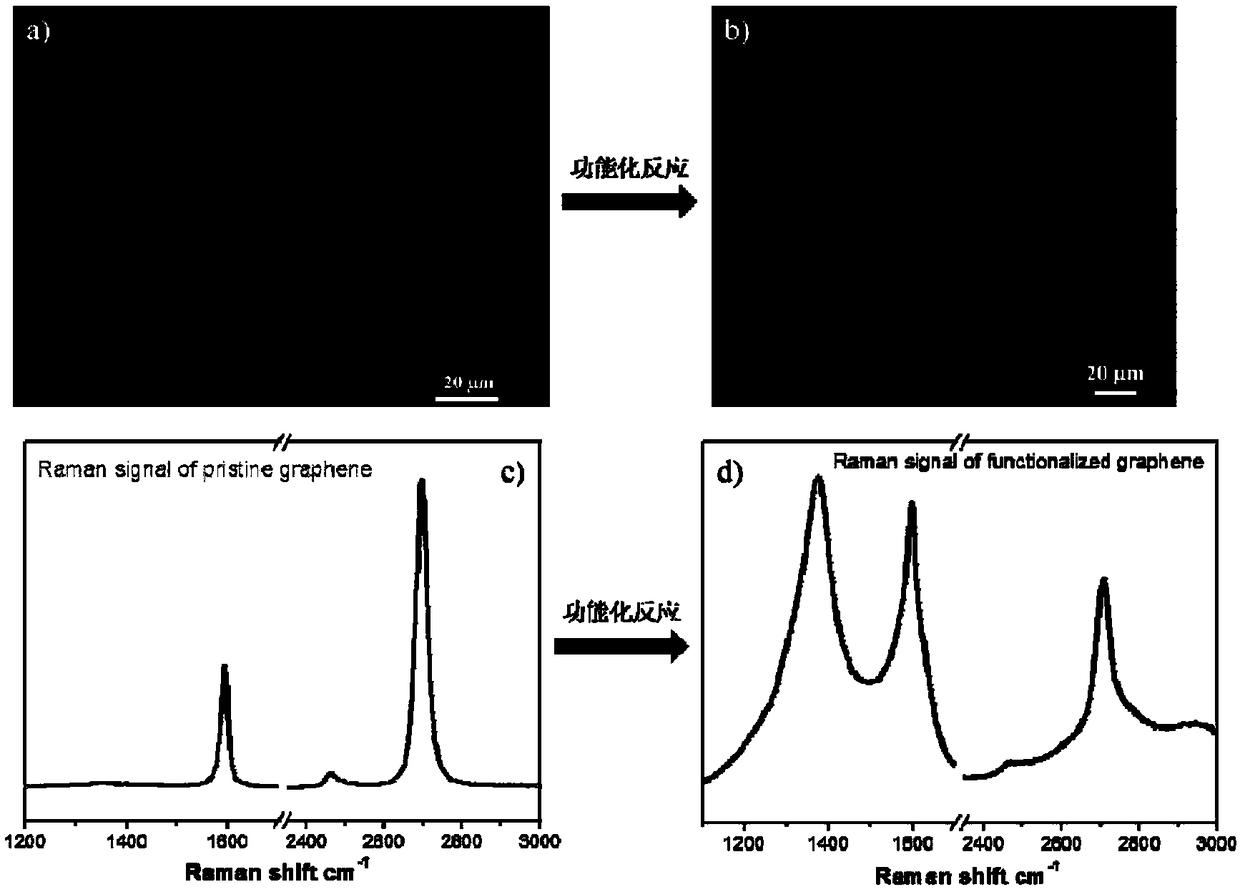

[0052] Embodiment 1, improve the chemical functionalization method of graphene thin film conductivity

[0053] Such as figure 1 Shown is the schematic diagram of the method of the present invention.

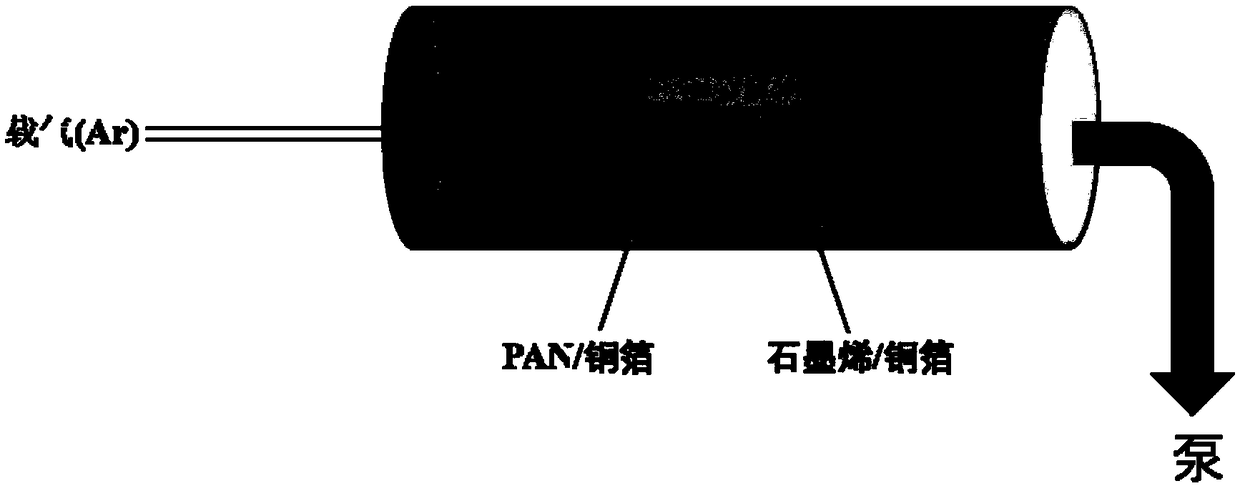

[0054] Such as figure 2 Shown, be the technological installation figure of the inventive method, concrete steps are as follows:

[0055] 1) The growth of graphene on the copper foil substrate adopts a low-pressure chemical vapor deposition system (LPCVD).

[0056]Copper foil (purity 99.8%, thickness 25 microns) was annealed in a hydrogen atmosphere for 30 minutes at 1000 ° C, the hydrogen flow rate was 300 sccm, and the system pressure was maintained at 350 Pa, and then annealed in an argon atmosphere for 30 minutes, and the argon flow rate was 500sccm, the system pressure is maintained at 500Pa. The function of annealing under hydrogen atmosphere is to reduce the oxide layer on the surface of copper foil, and the function of annealing under argon atmosphere is to reduce the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com