Wear-resistant transparent flame-retardant polycarbonate material and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of wear-resistant transparent flame-retardant polycarbonate material and its preparation, can solve the problems of affecting the light transmittance of the material and reducing the mechanical properties, so as to achieve good reinforcement effect and improve The effects of mechanical properties and light transmittance are small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

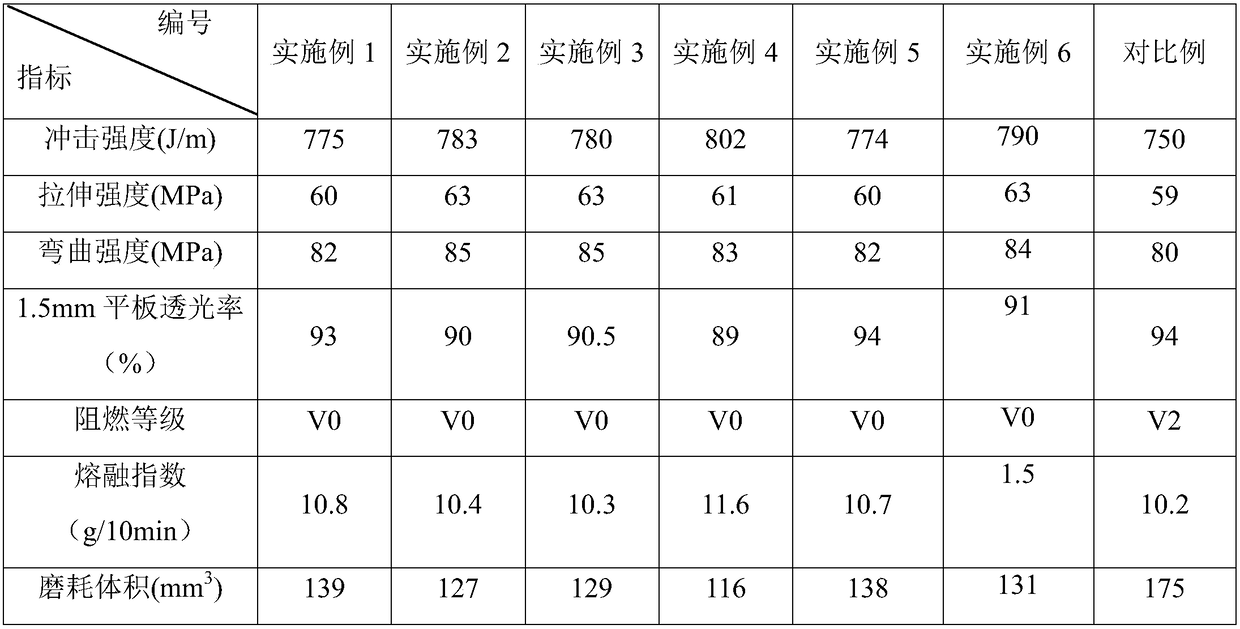

Examples

preparation example Construction

[0027] The preparation method of the transparent flame retardant masterbatch includes the steps of: adding all raw material components into a high-speed mixer with a rotation speed of 700-800r / min and mixing for 10-30min to obtain a mixture; The diameter ratio is (36-40):1, and the barrel temperature is 220-240 ° C in a twin-screw extruder, melted and mixed for 10-15 minutes under the protection of nitrogen, and then extruded and granulated to obtain a transparent flame-retardant masterbatch .

[0028]The invention provides a wear-resistant transparent flame-retardant polycarbonate material. The raw material components include: 90-95 parts by weight of polycarbonate, 5-10 parts by weight of transparent flame-retardant masterbatch, ZnO / SiO 2 0.5-1 weight part of the nanocomposite, 0.1-1 weight part of the antioxidant and 1-3 ppm of the coloring agent.

[0029] Among them, the polycarbonate is a bisphenol A type aromatic polycarbonate with a weight average molecular weight of 2...

Embodiment 1

[0037] This embodiment provides a transparent flame retardant masterbatch, the raw material components are calculated by weight, including: 85 parts of siloxane copolycarbonate, 8 parts of phosphorus flame retardant, 3 parts of heat stabilizer and 2 parts of dispersant; Among them, the siloxane copolycarbonate is a transparent siloxane copolycarbonate with a silicon content of 3% and a weight average molecular weight of 20,000 to 30,000; the phosphorus-based flame retardant is made of resorcinol-bis(diphenylphosphoric acid ester) and bisphenol A-bis(diphenyl phosphate) in a weight ratio of 1:1; the heat stabilizer is 2,4-bis[(dodecylthio)methyl]-6- methylphenol (DD); the dispersant is polyethylene wax;

[0038] The preparation method of the transparent flame retardant masterbatch includes the steps of: adding all raw material components into a high-speed mixer with a rotation speed of 750r / min and mixing for 10 minutes to obtain a mixture; putting the mixture into a 1. In a t...

Embodiment 2

[0042] This embodiment provides a transparent flame retardant masterbatch. The raw material components are calculated in parts by weight, including: 90 parts of siloxane copolycarbonate, 5 parts of phosphorus flame retardant, 2 parts of heat stabilizer and 1 part of dispersant; Among them, the siloxane copolycarbonate is a transparent siloxane copolycarbonate with a silicon content of 3% and a weight average molecular weight of 20,000 to 30,000; the phosphorus-based flame retardant is made of resorcinol-bis(diphenylphosphoric acid ester) and bisphenol A-bis(diphenyl phosphate) in a weight ratio of 1:1; the heat stabilizer is 2,4-bis[(dodecylthio)methyl]-6- methylphenol (DD); the dispersant is polyethylene wax;

[0043] The preparation method of the transparent flame retardant masterbatch includes the steps of: adding all raw material components into a high-speed mixer with a rotation speed of 700r / min and mixing for 30 minutes to obtain a mixture; 1. In a twin-screw extruder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com