Transparent heat insulation film for building glass and preparation method of film

A technology for film preparation and building, applied in the direction of coating, etc., can solve the problems of unification of heat insulation effect and high light transmittance, and reduce the light transmittance of glass, which is beneficial to energy saving and emission reduction. Good heat insulation effect, little effect on light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

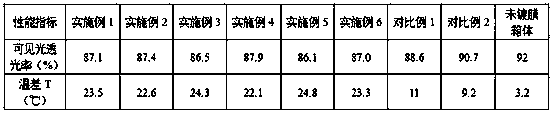

Examples

Embodiment 1

[0028] (1) Add nano-indium tin oxide powder and methyl ethyl ketone into a ball mill for ball milling until the average particle size is 10nm, then add γ-methacryloxypropyl trimethoxysilane and ultrasonically treat for 28 minutes to obtain indium tin oxide Dispersion liquid; in the indium tin oxide dispersion liquid, 3 weight parts of nano-indium tin oxide powder, 94 weight parts of methyl ethyl ketone, 3 weight parts of gamma-methacryloyloxypropyltrimethoxysilane; in the nano-indium tin oxide, indium oxide The weight ratio of compound and tin oxide is 9:1;

[0029] (2) Add lanthanum nitrate nonahydrate, ammonium heptamolybdate hexahydrate, ascorbic acid, glucose, and disodium edetate into deionized water, stir magnetically until completely dissolved, adjust the pH value to 7.5 with ammonia water, and then heat the reaction in a water bath The wet gel was obtained, dried at 170°C for 17 hours to obtain a dry gel, calcined at high temperature, and ground to an average particle ...

Embodiment 2

[0033](1) Add nano-indium tin oxide powder and methyl ethyl ketone into a ball mill for ball milling until the average particle size is 12nm, then add γ-methacryloxypropyl trimethoxysilane and ultrasonically treat for 35 minutes to obtain indium tin oxide Dispersion liquid; in the indium tin oxide dispersion liquid, 2.5 parts by weight of nano-indium tin oxide powder, 94 parts by weight of methyl ethyl ketone, 3.5 parts by weight of γ-methacryloxypropyl trimethoxysilane; in the nano-indium tin oxide, indium oxide The weight ratio of compound and tin oxide is 9:1;

[0034] (2) Add lanthanum nitrate nonahydrate, ammonium heptamolybdate hexahydrate, ascorbic acid, glucose, and disodium edetate into deionized water, stir magnetically until completely dissolved, adjust the pH value to 7.5 with ammonia water, and then heat the reaction in a water bath The wet gel was obtained, dried at 160°C for 17 hours to obtain a dry gel, calcined at high temperature, and ground to an average par...

Embodiment 3

[0038] (1) Add nano-indium tin oxide powder and methyl ethyl ketone into a ball mill for ball milling until the average particle size is 18nm, then add γ-methacryloxypropyl trimethoxysilane and ultrasonically treat for 35 minutes to obtain indium tin oxide Dispersion liquid; in the indium tin oxide dispersion liquid, 3.5 parts by weight of nanometer indium tin oxide powder, 92 parts by weight of methyl ethyl ketone, 4.5 parts by weight of γ-methacryloxypropyl trimethoxysilane; in the nanometer indium tin oxide, indium oxide The weight ratio of compound and tin oxide is 9:1;

[0039] (2) Add lanthanum nitrate nonahydrate, ammonium heptamolybdate hexahydrate, ascorbic acid, glucose, and disodium edetate into deionized water, stir magnetically until completely dissolved, adjust the pH value to 8.5 with ammonia water, and then heat the reaction in a water bath The wet gel was obtained, dried at 170°C for 16 hours to obtain a dry gel, calcined at high temperature, and ground to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com