Hydrophobic dust-proof coating for greenhouse film, a preparing method thereof and applications of the coating

A dust-proof coating and hydrophobic technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve unfavorable industrial production and environmental protection, difficulty in large-scale promotion and application, complicated coating preparation process, etc. problems, to achieve the effect of easy industrial production and large-scale application, increase storage stability, and good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 24g of modified fluorocarbon resin to the beaker, add 33.6g of propylene glycol methyl ether acetate, place on a magnetic stirrer, set the speed at 200r / min, room temperature, stir for 10min, fully react, mix well; add 2.4g of toluene diisocyanate , placed on a magnetic stirrer, set the speed at 800r / min, room temperature, stirred for 30min, fully reacted, mixed evenly, and then filtered with 300 mesh gauze to make a mixed emulsion of hydrophobic coating; add 5% deionized water, dilute to construction Viscosity: use 9# coating rod, scrape coating on the plastic film, and let it stand at room temperature for 5 minutes; put the film coated with hydrophobic coating in an oven, and dry it at 70°C for 100 min to obtain the fluorocarbon resin hydrophobic dustproof coating finished layer.

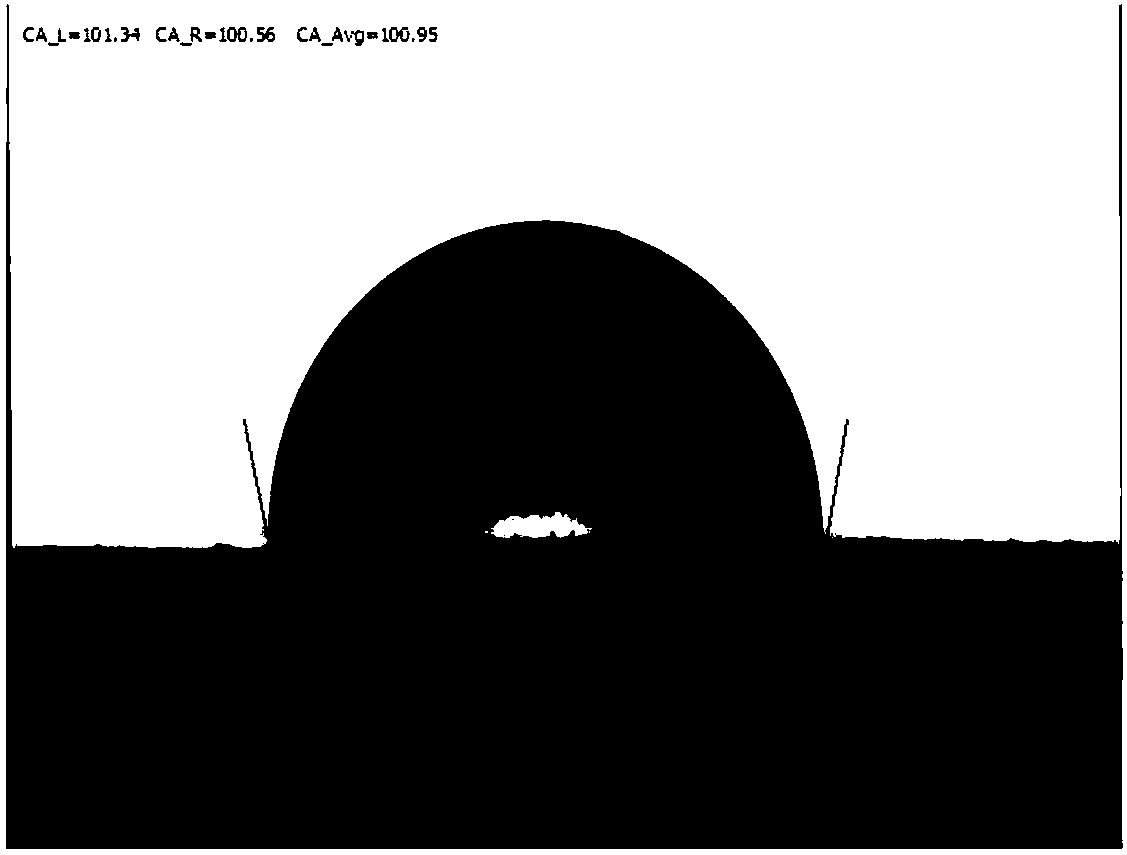

[0034] After testing, the thickness of the hydrophobic and dust-proof coating is 10um, the contact angle between the coating surface and water is 95.4°, and there is no fogging after 5 ...

Embodiment 2

[0036] Add 28g modified fluorocarbon resin to the beaker, add 0.7g silicone modified methyl acrylate, ethyl acrylate mixed solution and 32.9g propylene glycol methyl ether acetate, place on a magnetic stirrer, set the speed at 300r / min, Stir at room temperature for 12 minutes, fully react, mix evenly; add 8.4g of diphenylmethane diisocyanate, place on a magnetic stirrer, set the speed at 850r / min, room temperature, stir for 35min, fully react, mix evenly, and then use 250 mesh gauze Filter to make a mixed emulsion of hydrophobic paint; add 6% deionized water and dilute to the construction viscosity; use a 14# film stick to scrape and coat on the plastic film, and let it stand at room temperature for 6 minutes; put the film coated with hydrophobic paint Put it into an oven and dry at 75°C for 120 minutes to get the finished fluorocarbon resin hydrophobic and dustproof coating.

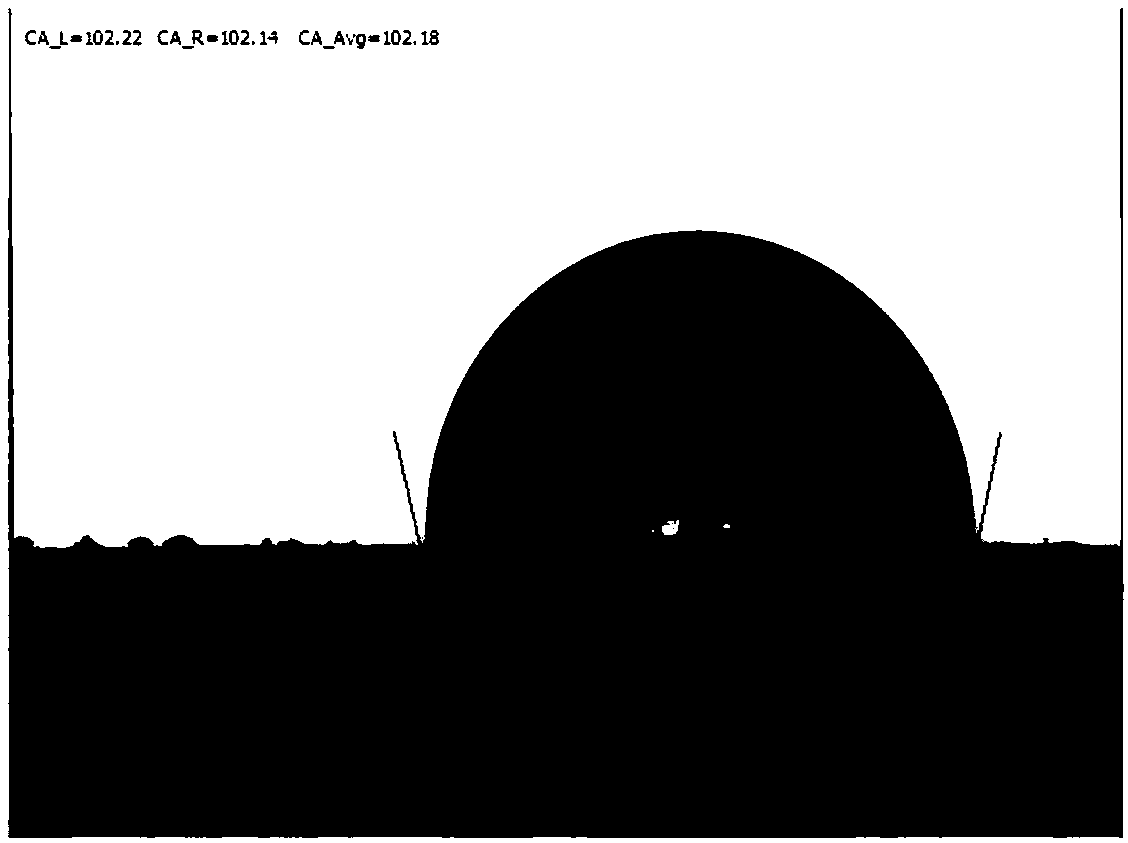

[0037] After testing, the thickness of the hydrophobic and dust-proof coating is 13um, the contact a...

Embodiment 3

[0039] Add 42.6g of modified fluorocarbon resin to the beaker, add 15g of propylene glycol methyl ether acetate, place it on a magnetic stirrer, set the speed at 400r / min, room temperature, stir for 15min, fully react, and mix well; add 2.4g of diphenyl Methane diisocyanate, placed on a magnetic stirrer, set the speed at 900r / min, room temperature, stirred for 35min, fully reacted, mixed evenly, then filtered with 240 mesh gauze to make a mixed emulsion of hydrophobic coating; add 6% deionized water, Dilute to the construction viscosity; use a 22# coating stick to scrape on the plastic film, and let it stand at room temperature for 6 minutes; put the film coated with the hydrophobic coating in an oven, and dry it at 80°C for 120 minutes to obtain the fluorocarbon resin hydrophobic Dustproof coating finished.

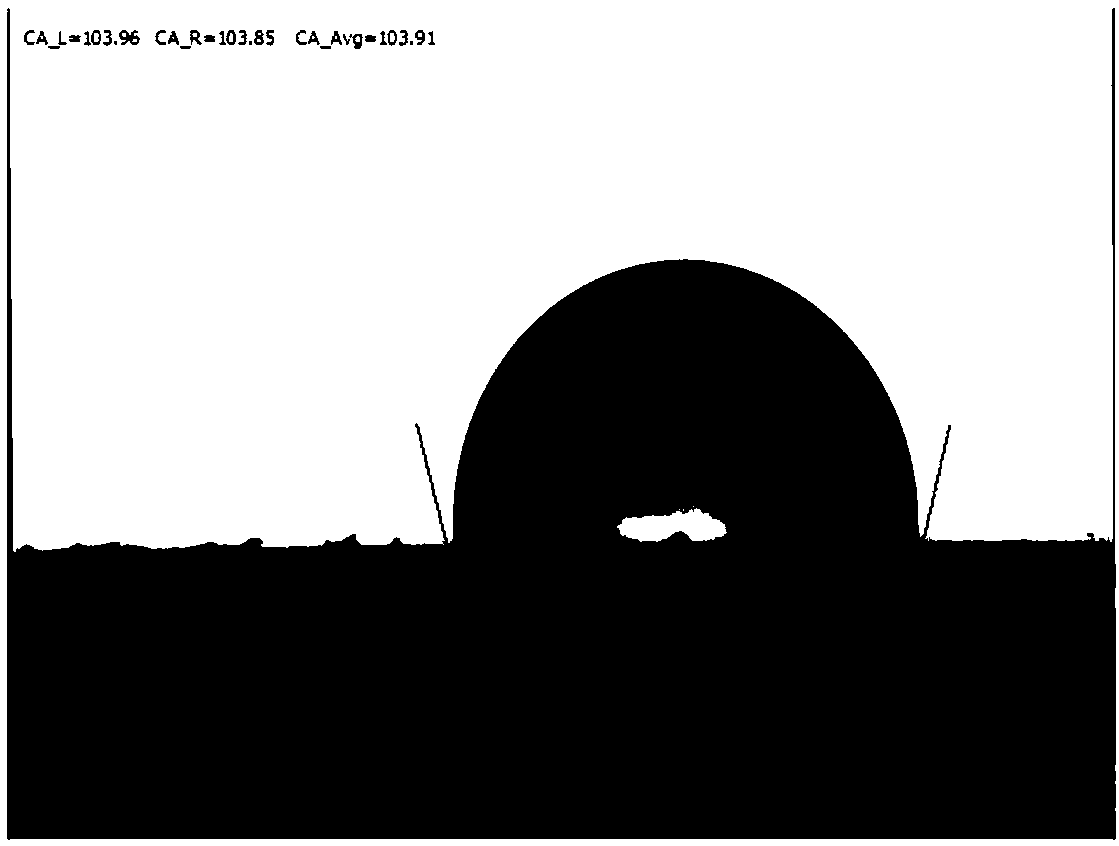

[0040]After testing, the thickness of the hydrophobic and dust-proof coating is 16um, the contact angle between the coating surface and water is 100.9°, and there is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com