Greenhouse thin film water-based hydrophobic coating as well as preparation method and application thereof

A hydrophobic coating and water-based technology, applied in the coating and other directions, can solve the problems that the adhesion between the coating and the film needs to be improved, it is not easy to popularize and apply on a large scale, and the curing temperature of the hydrophobic coating is high. The effect of stability and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

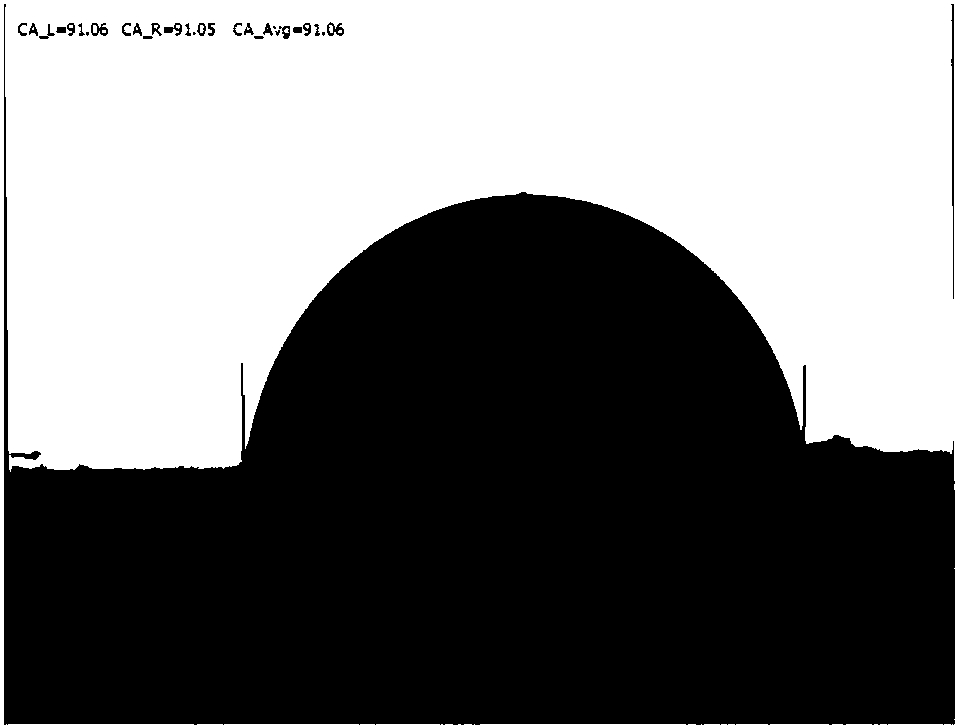

[0033] Add 57g of modified fluorocarbon resin to the beaker, while stirring continuously with a glass rod, add 2.4g of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.5g of fatty acid ester Sulfate, 0.3g polydimethylsiloxane silicone oil, 1.0g polysilane containing ammonia functional group, placed on a magnetic stirrer, set the speed at 200r / min, room temperature, stirred for 10min, fully reacted, mixed evenly; add 3.8g Toluene diisocyanate, placed on a magnetic stirrer, set the speed at 800r / min, room temperature, stirred for 30min, fully reacted, mixed evenly; then added 35g of liquid paraffin, set the speed at 200r / min, room temperature, stirred for 15min, fully reacted, mixed evenly , and then filtered with 300-mesh gauze to make a mixed emulsion of water-based hydrophobic paint; add 3% deionized water and dilute to the construction viscosity; use a 9# coating stick to scrape on the plastic film, and let it stand for 5 minutes at room temperature; Put the film coated wi...

Embodiment 2

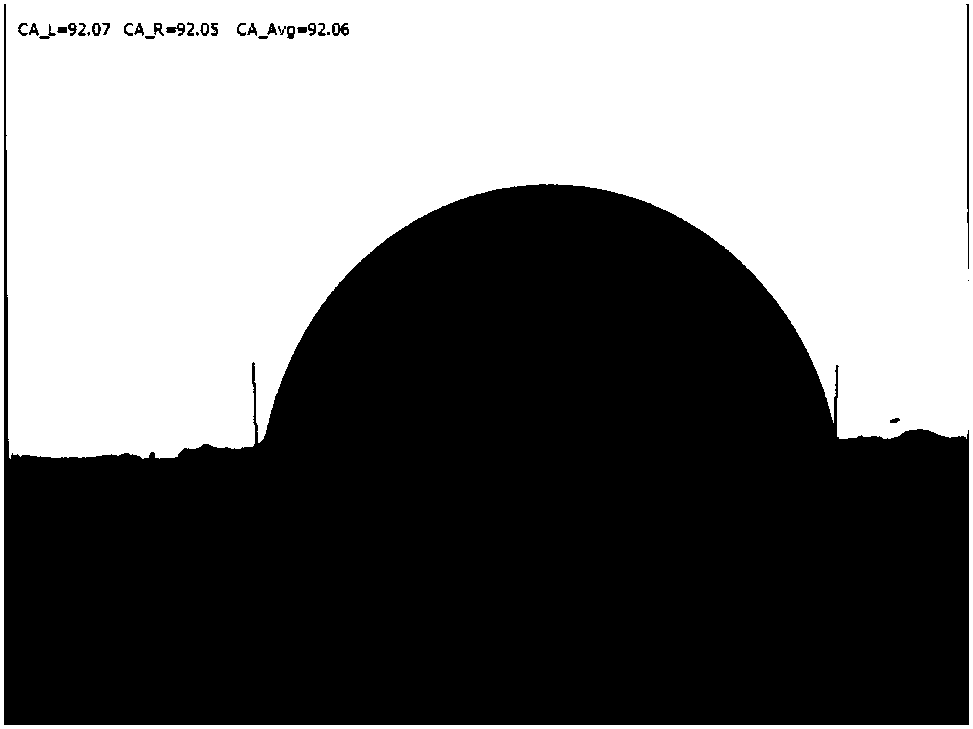

[0036] Add 34g of modified fluorocarbon resin to the beaker, while stirring continuously with a glass rod, add 1.75g of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.3g of polyether silicon Oxane copolymer, 0.25g polydimethylsiloxane silicone oil, 0.2g polyacrylamide, 0.7g amino functional polysilane, finally add 0.05g polydimethylsiloxane silicone oil, place on a magnetic stirrer , set the speed at 300r / min, room temperature, stir for 12min, fully react, and mix evenly; add 2.25g of toluene diisocyanate, place it on a magnetic stirrer, set the speed at 900r / min, room temperature, stir for 35min, fully react, and mix evenly; Add 10.5g of liquid paraffin, set the speed at 300r / min, room temperature, stir for 12min, fully react, mix evenly, and then filter with 250 mesh gauze to make a mixed emulsion of water-based hydrophobic coating; add 5% deionized water and dilute to the construction viscosity ; Use a 14# film stick to scrape and coat the plastic film, and let it sta...

Embodiment 3

[0039]Add 19g of modified fluorocarbon resin to the beaker, while stirring continuously with a glass rod, add 1.1g of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.15g of polyoxyethylene Mixed emulsion of copolymer and polyether siloxane copolymer, 0.15g polyether polyester modified organosiloxane, 0.2g aminoalcohol complex titanate, 0.4g amino functional polysilane, and finally add 0.04 g polyether modified methyl siloxane silicone oil, placed on a magnetic stirrer, set the speed at 400r / min, room temperature, stirred for 15min, fully reacted, mixed evenly; added 1.4g diphenylmethane diisocyanate, placed on a magnetic stirrer On the device, set the speed at 900r / min, room temperature, stir for 35min, fully react, and mix evenly; then add 2.56g of liquid paraffin, set the speed at 400r / min, room temperature, stir for 12min, fully react, mix evenly, and then filter with 240 mesh gauze , to make a mixed emulsion of water-based hydrophobic paint; add 6% deionized water and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com