Environment-friendly flame-retardant transparent polyester material

A polyester material, an environmentally friendly technology, applied in the field of environmentally friendly flame retardant transparent polyester materials, can solve the problems of low flame retardant efficiency, poor quality reproducibility, low flame retardant efficiency, etc., and achieve high flame retardant efficiency and thermal stability. performance, improve processability, and small mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

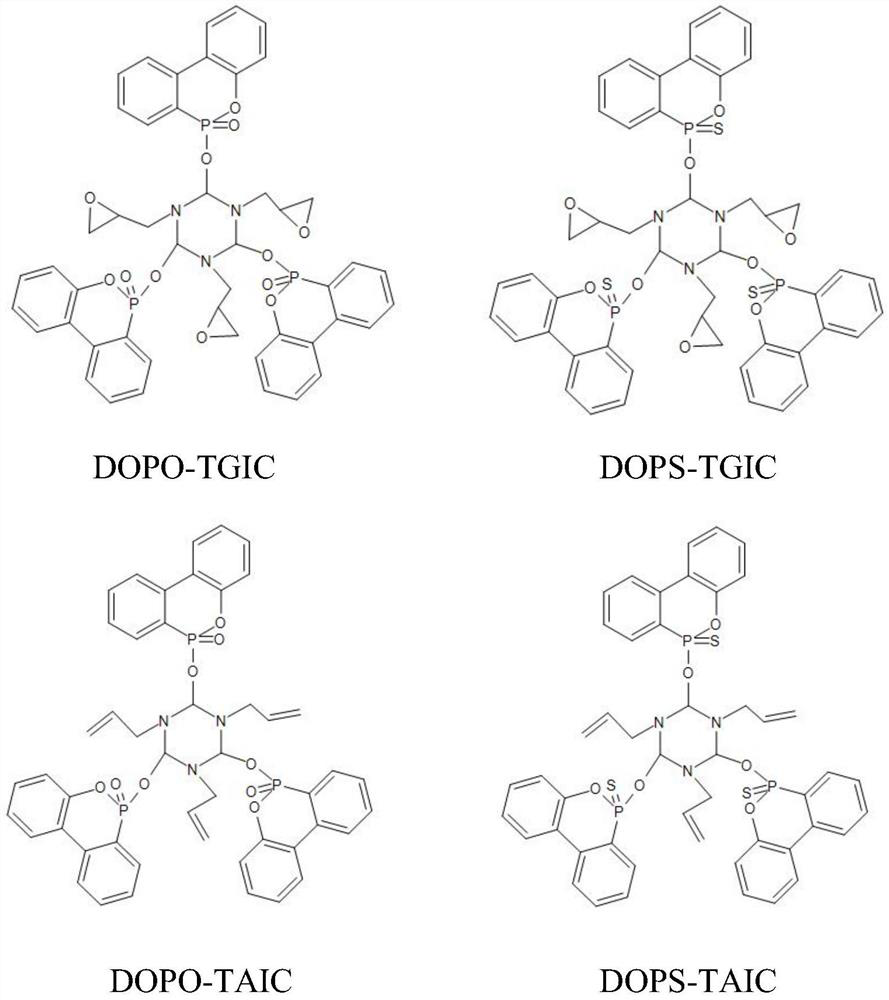

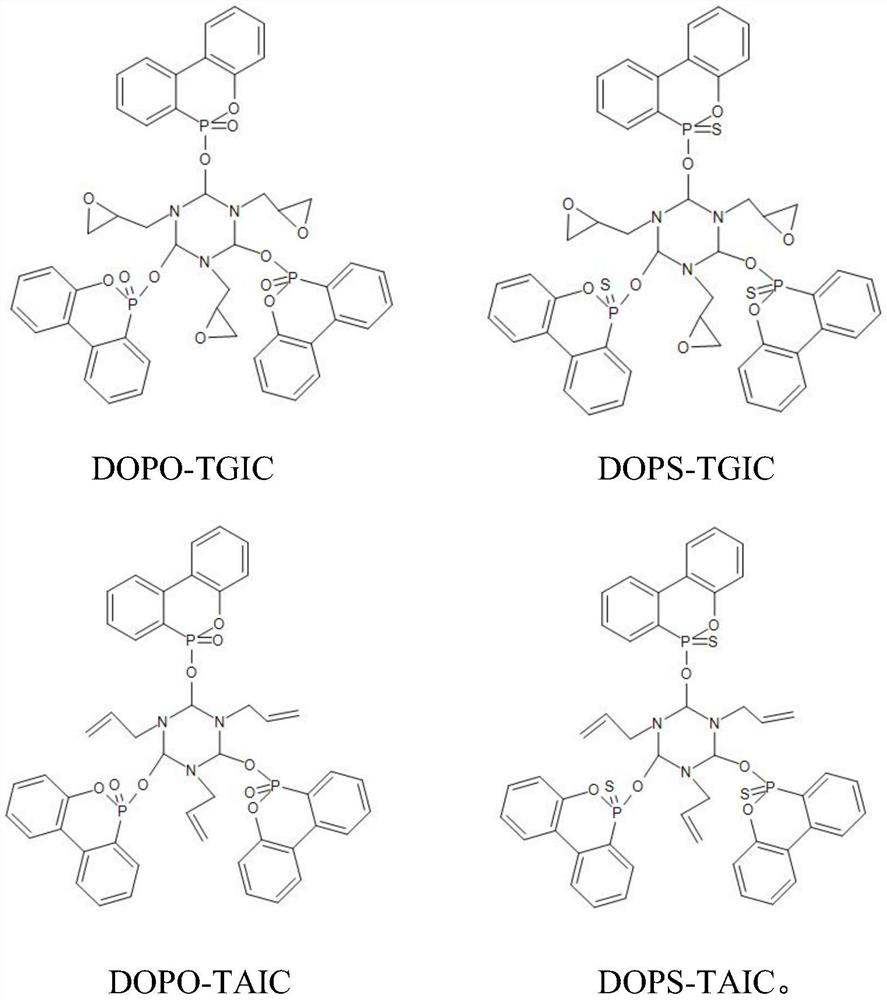

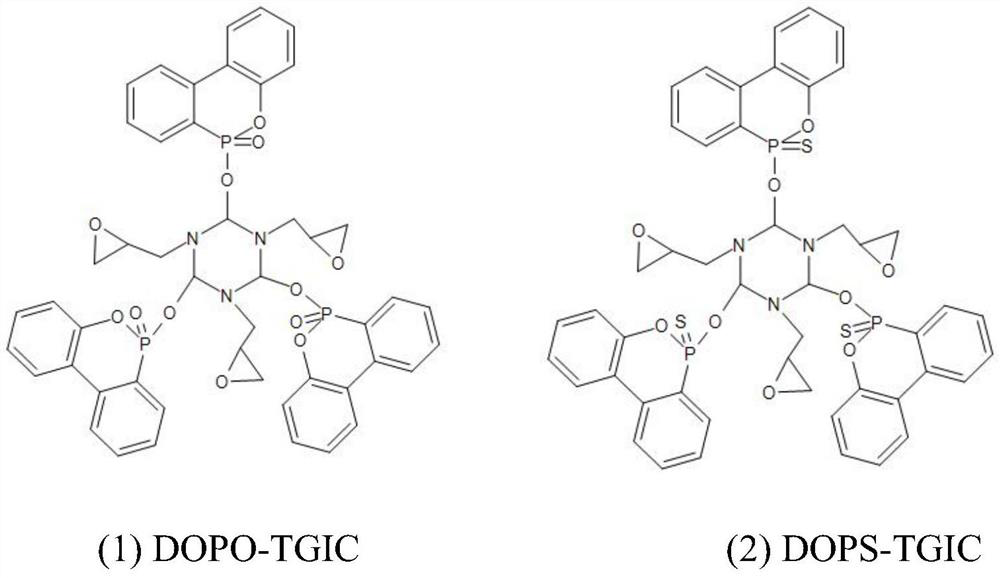

[0023] The invention provides an environment-friendly flame-retardant transparent polyester material, which is composed of polyester resin, DOPO derivatives, and an antioxidant. The polyester resin may be one of polycarbonate (PC), polymethyl methacrylate (PMMA, acrylic), and polyethylene terephthalate (PET). Because described polycarbonate (PC), polymethyl methacrylate (PMMA, acrylic), polyethylene terephthalate (PET), itself should be prior art, and for those skilled in the art The known transparent polyester material will not be repeated here. In the environment-friendly flame-retardant transparent polyester material, the polyester resin has a mass percentage content of 70%-95%. The structural formula of the DOP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com