Processing system and processing method for glass cover plate

A technology of glass cover plate and processing system, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low yield and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

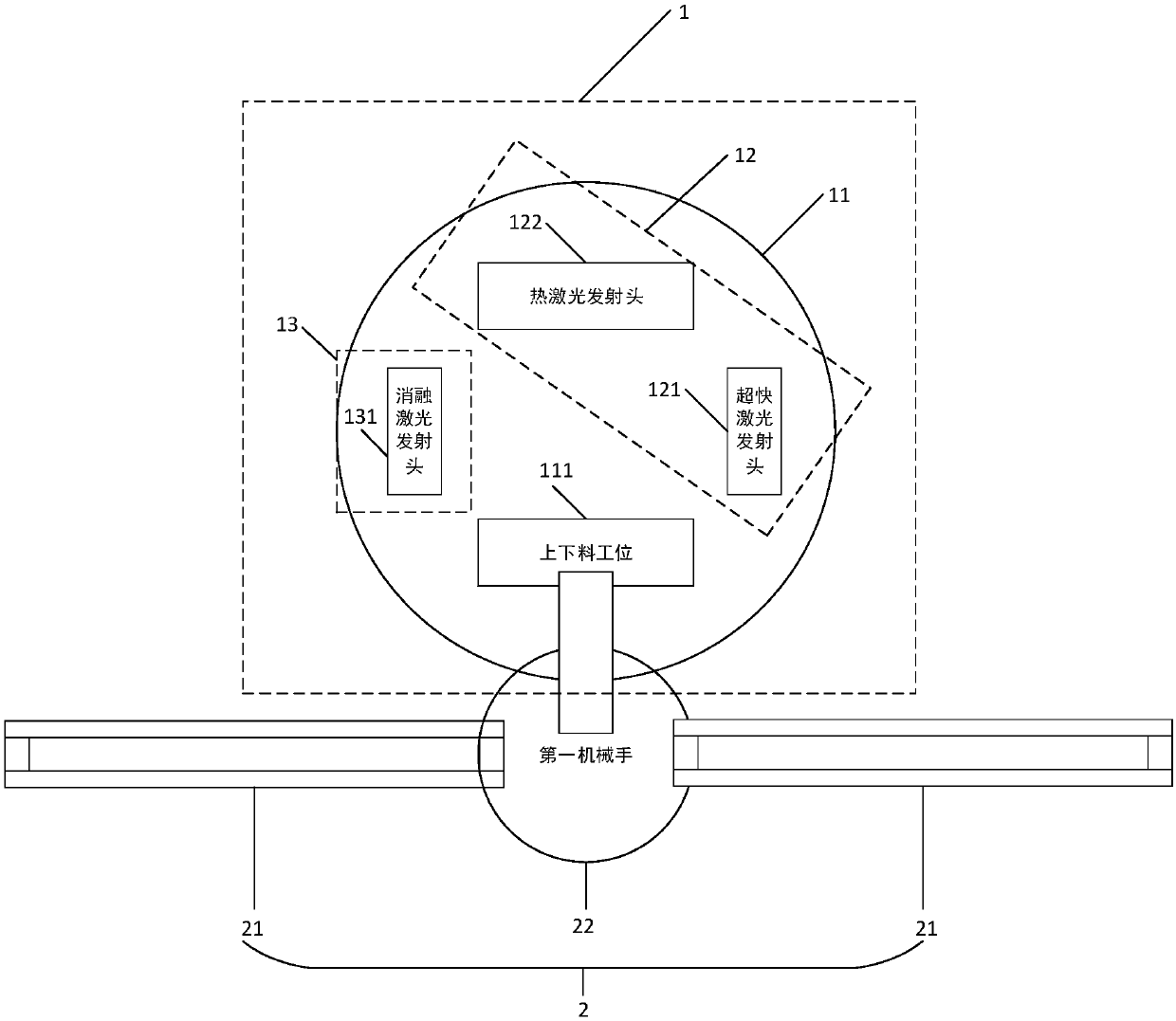

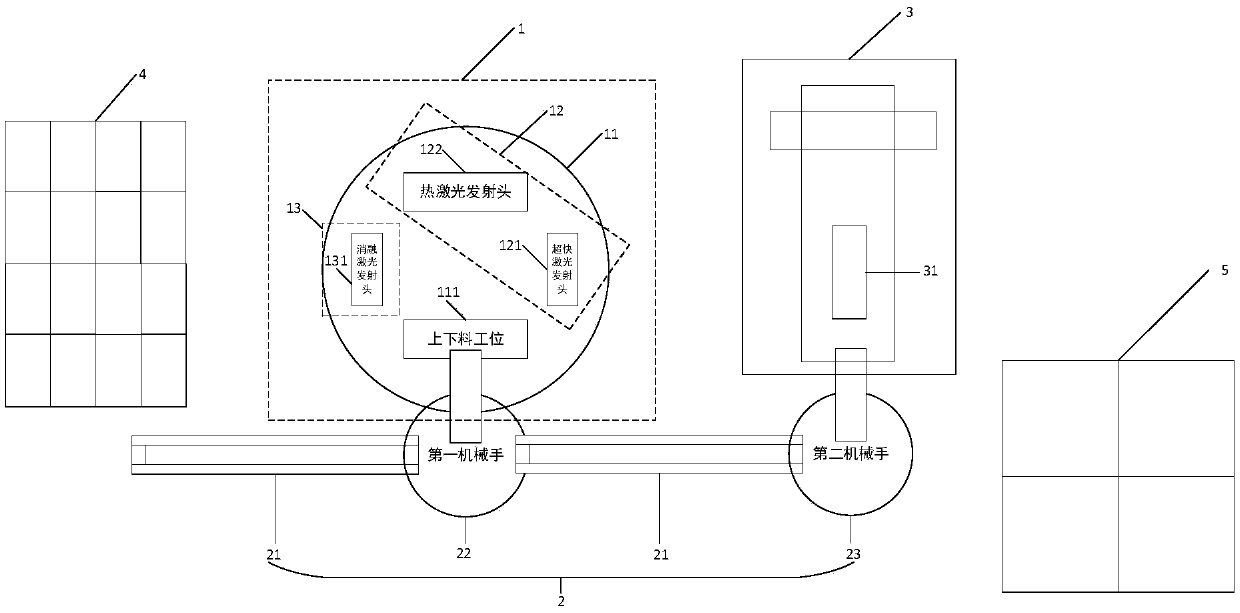

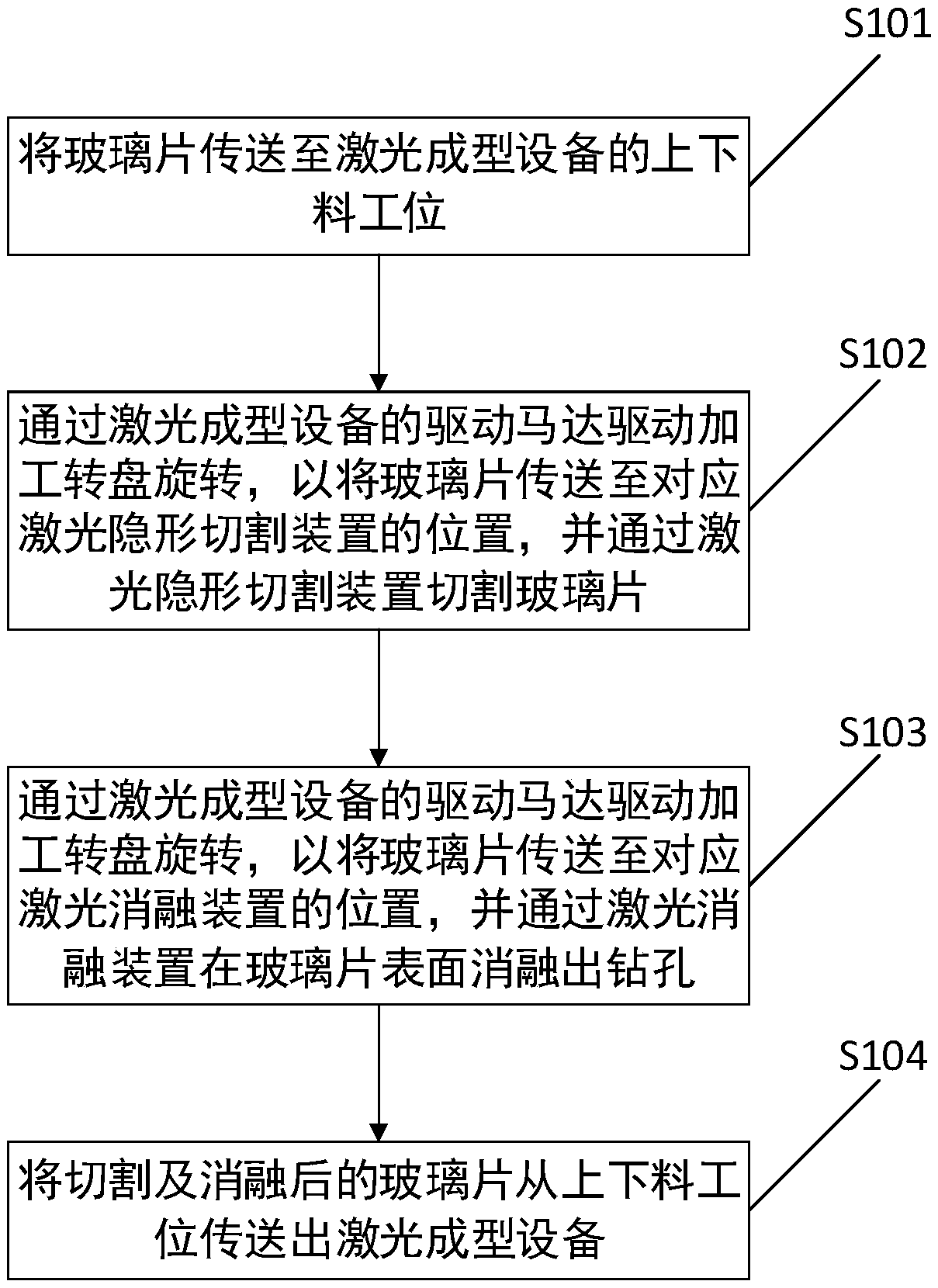

[0053] The core of the invention is to provide a processing system for a glass cover plate. In the prior art, the cutting equipment mainly used for cutting the glass cover plate in the processing system is usually a diamond tip or a hard alloy grinding wheel cutter, and the cutting equipment is used to directly cut a crack on the surface of the glass; then use The glass is divided along the crack line by mechanical means; then the glass cover plate is drilled and roughly ground by CNC drilling equipment; finally, the glass cover plate is finely ground and polished by CNC polishing equipment.

[0054] However, there are some drawbacks when using the above system to score and cut the glass cover: the cutting equipment will cause large chips, chips and micro-cracks, which will reduce the strength of the cutting edge; The risk of fragmentation will be caused during processing, which reduces the yield of finished products. It takes a long time to use CNC drilling equipment for dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com