Polysilsesquioxane aerogel and preparation method thereof

A technology of polysilsesquioxane and airgel, which is applied in the field of airgel, can solve the problems that research work has not received due attention, impurities such as surfactants are difficult to completely remove, and the application range of materials is limited. Achieve good tolerance, reduce irreversible shrinkage, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 10 mL of methyltriethoxysilane (MTES) with 2.0 mL of deionized water, 6.0 mL of absolute ethanol, and 0.5 uL of 40% HF aqueous solution, stir and react at 60° C. for more than 30 minutes and then cool to room temperature. Add 2.0 mL of deionized water, 6.0 mL of absolute ethanol, and 100 uL of triethylamine to the above solution. Leave to stand at 15℃ or above to form a gel, and age at 25℃ or above for more than 3 hours. It was washed three times with ethanol and three times with n-hexane. Drying at room temperature and pressure for more than 12 hours, with a heating rate of 2°C / min to 80°C, and holding for more than 1 hour; heating to 200°C or more at a heating rate of 3°C / min and holding for more than 2 hours to complete the drying.

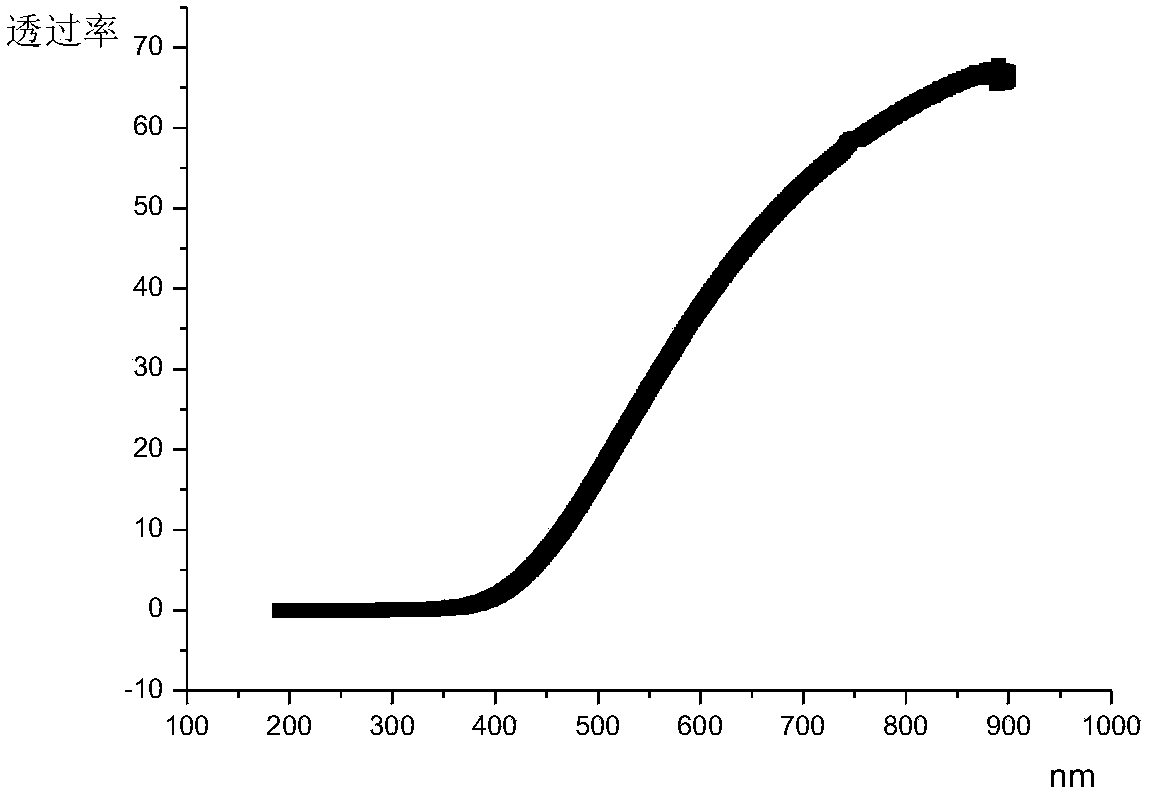

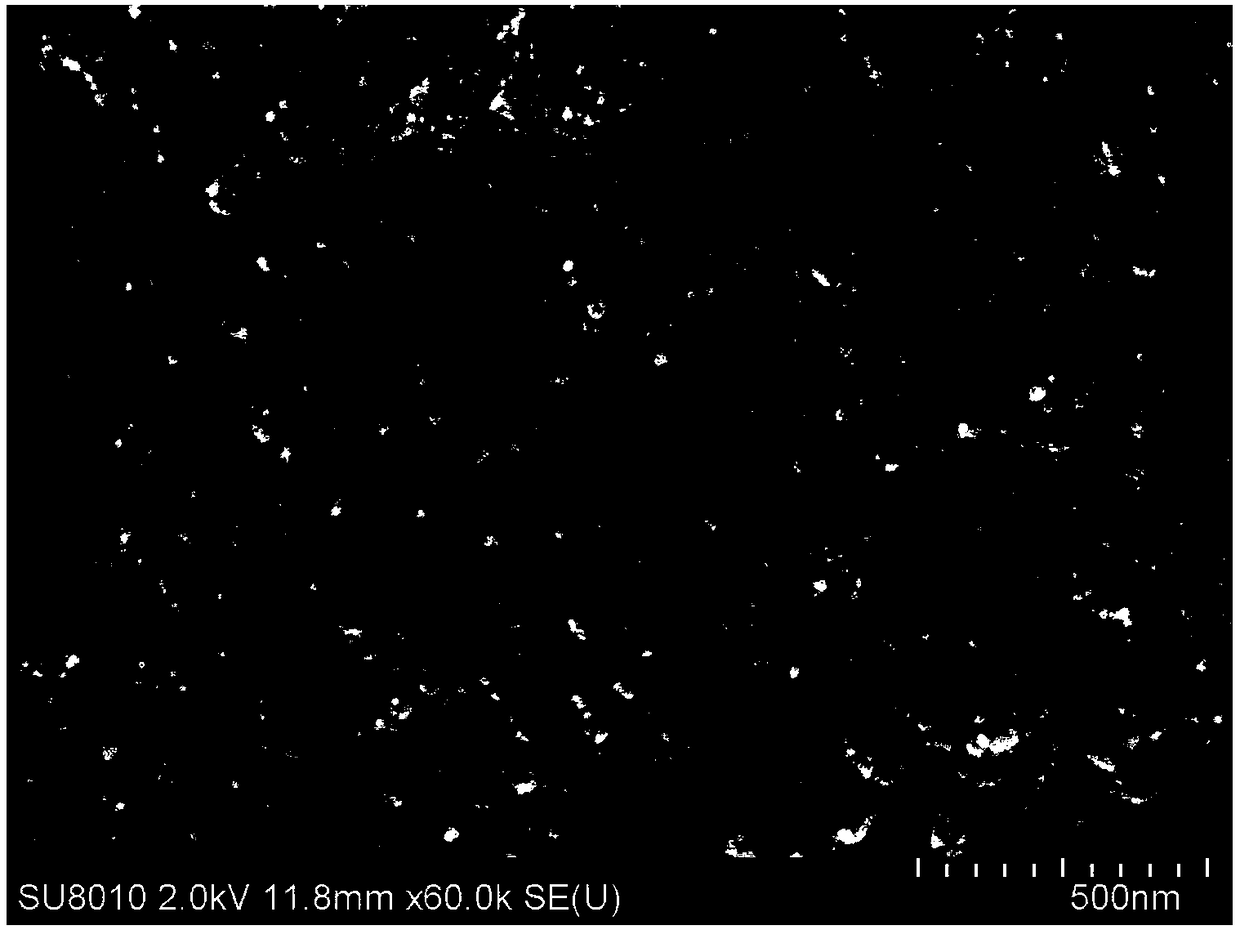

[0039] Its density is 0.19g / cm 3 , The average pore diameter is 9.3nm, the static contact angle with water is 123°, the visible light transmittance at 700nm is 63%, and the transmittance of 190-400nm ultraviolet light region is less th...

Embodiment 2

[0041] Mix 10 mL of methyl trimethoxysilane (MTMS) with 3.0 mL of deionized water, 7.0 mL of propanol, and 0.7 uL of 40% HF aqueous solution, stir and react at 15°C for at least 30 minutes, and then cool to room temperature. Add 7.0 mL of deionized water, 2.5 mL of propanol, and 0.7 mL of 40% tetrabutylammonium hydroxide solution to the above solution. Leave to stand at 15℃ or above to form a gel, and age at 25℃ or above for more than 3 hours. Wash three times with propanol and three times with n-pentane. The drying procedure is similar to that of Example 1, but after the temperature is raised to 80 degrees Celsius, it becomes a reduced pressure operation to remove volatile impurities as much as possible, and the pressure value is not higher than 0.85 atm.

[0042] Its density is 0.16g / cm 3 , The average pore size is 9.6nm, the static contact angle with water is 122°, the visible light transmittance at 700nm is 64%, and the transmittance in the ultraviolet region of 190-400nm is...

Embodiment 3

[0044] The operation is similar to Example 2, but the tetrabutylammonium hydroxide solution in Example 2 is replaced with a tetraethylammonium hydroxide solution. Before drying, soak the gel with 1% 1H,1H,2H,2H-perfluorooctyltrichlorosilane petroleum ether solution equal to the volume of the gel for more than 3h, 1H,1H,2H,2H-perfluorooctyltrichlorosilane The concentration of the solution is preferably 30% or less.

[0045] Its density is 0.15g / cm 3 , The average pore diameter is 12.1nm, the static contact angle with water is 143°, the visible light transmittance at 700nm is 54%, and the transmittance in the ultraviolet region of 190-400nm is less than 1%. Soaking in water, 0.1M HCl solution, 3.5% NaCl solution, 0.1M NaOH solution and other systems for more than three hours can keep it intact, and the contact angle can still be kept above 120° after soaking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com