Biomembrane reactor, waste water treating system and method for treating waste water

A biofilm reactor and wastewater technology, which is applied in the field of biofilm reactor, wastewater treatment system and wastewater treatment, can solve the problems of easy blockage, waste of water and gas resources, and reduce wastewater treatment efficiency, so as to achieve less blockage and save treatment. The effect of low cost and pollutant content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

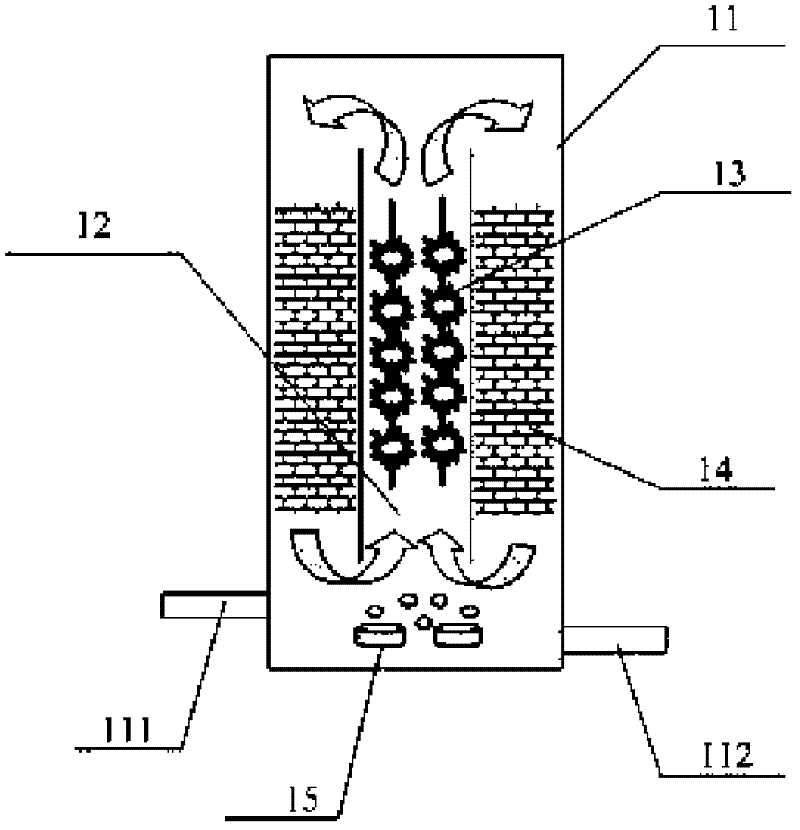

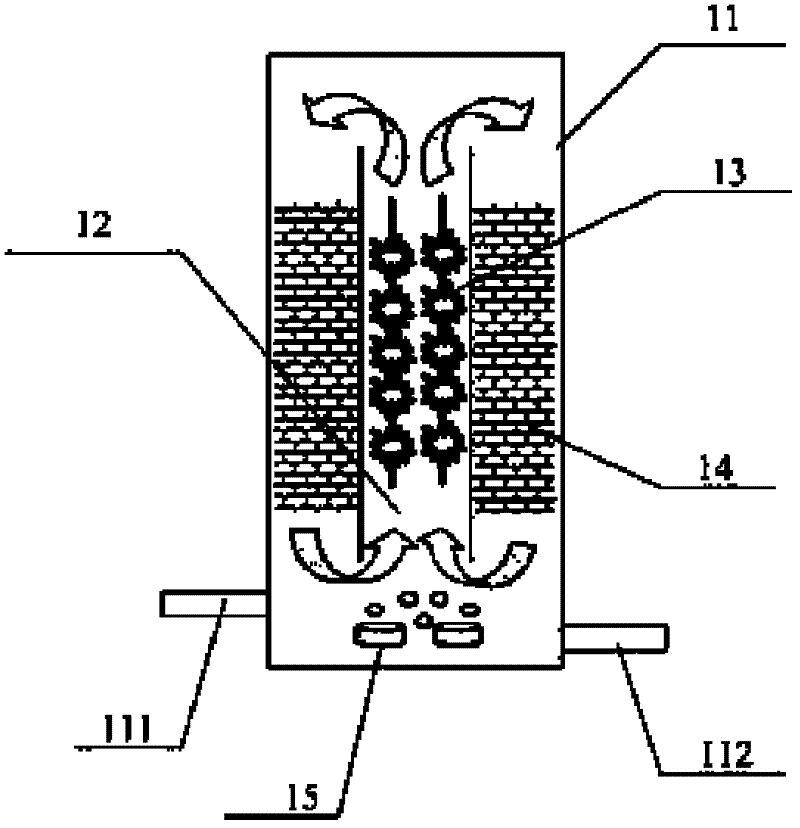

[0074] Embodiment 1 biofilm reactor

[0075] The biofilm reactor structure is as figure 1 As shown, it includes an outer cylinder 11, an inner cylinder 12 arranged inside the outer cylinder 11, a semi-soft filler filled inside the inner cylinder 12, and shale ceramsite filled between the outer cylinder 11 and the inner cylinder 12 Filter material, the aeration head that is arranged on the bottom of outer cylinder 11 and communicates with inner cylinder 12, the parameter of this biofilm reactor is as follows:

[0076] Outer cylinder: height 5.5m, diameter 2.8m, effective water depth 4.8m, effective volume 30.0m 3 , the hydraulic retention time is 1.5h;

[0077] Inner cylinder: 1.8m in diameter, the distance between the bottom of the inner cylinder and the bottom of the outer cylinder is 0.3m, and the distance between the top of the inner cylinder and the top of the outer cylinder is 0.3m;

[0078] The semi-soft packing is semi-soft hanging packing purchased from Yixing Yilan...

Embodiment 2

[0080] Embodiment 2 waste water treatment system

[0081] The wastewater treatment system includes: a water diversion tube, a cyclone separator whose water inlet is connected to the water outlet of the water diversion tube, a lift pump whose water inlet is connected to the water outlet of the cyclone separator, a water inlet connected to the water outlet of the lift pump, and an implementation The biofilm reactor provided in Example 1, the inclined plate settler whose water inlet is connected to the water outlet of the biofilm reactor, and the sludge return pump connected to the sludge outlet of the inclined plate settler are aerated using a Roots blower; wherein, The parameters of each device are as follows:

[0082] Water diversion cylinder: diameter 0.85m, length 1.17m, volume 0.66m 3 ;

[0083] Lifting pump: flow rate 20.0m 3 / h, lift 10.0m;

[0084] Cyclone separator: processing capacity 20.0m 3 / h~29.0m 3 / h, diameter 273mm, height 1350mm, head loss 4m~5m;

[0085...

Embodiment 3

[0088] Embodiment 3 biofilm reactor

[0089] The biofilm reactor structure is as figure 1 As shown, it includes an outer cylinder 11, an inner cylinder 12 arranged inside the outer cylinder 11, a semi-soft filler filled inside the inner cylinder 12, and shale ceramsite filled between the outer cylinder 11 and the inner cylinder 12. Filter material, the aeration head that is arranged on the bottom of outer cylinder 11 and communicates with inner cylinder 12, the parameter of this biofilm reactor is as follows:

[0090] Outer cylinder: height 0.8m, diameter 0.5m, effective water depth 0.6m, effective volume 117L, hydraulic retention time 4h;

[0091] Inner cylinder: 0.5m in diameter, the distance between the bottom of the inner cylinder and the bottom of the outer cylinder is 0.1m, and the distance between the top of the inner cylinder and the top of the outer cylinder is 0.1m;

[0092] The semi-soft packing is semi-soft hanging packing purchased from Yixing Yilan Environmental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com