Patents

Literature

48results about How to "Comb evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

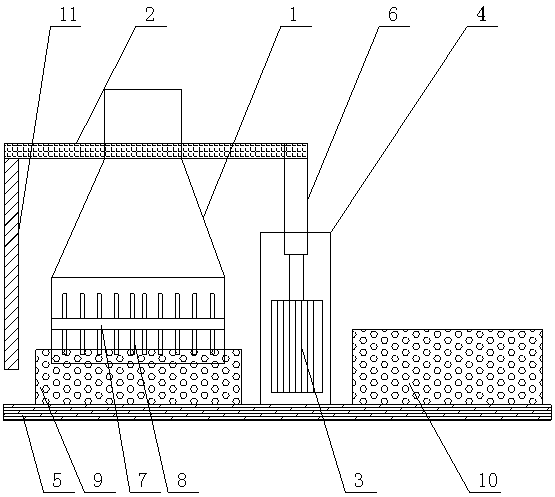

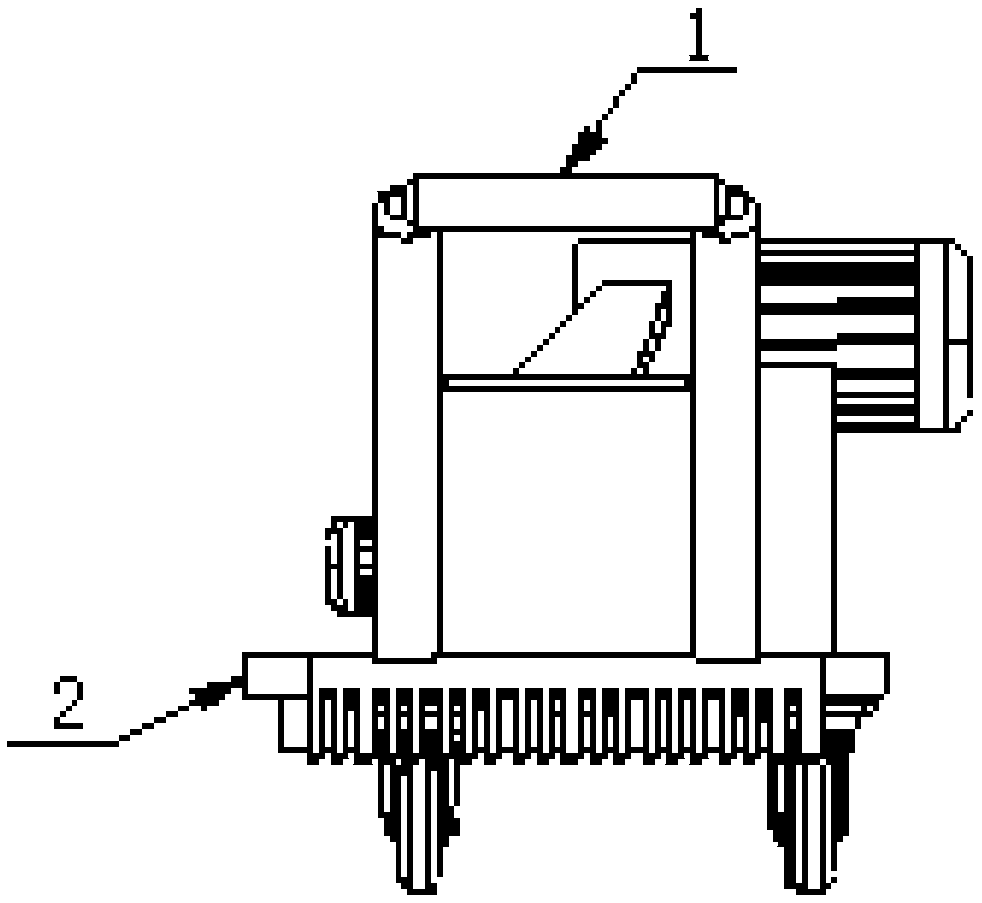

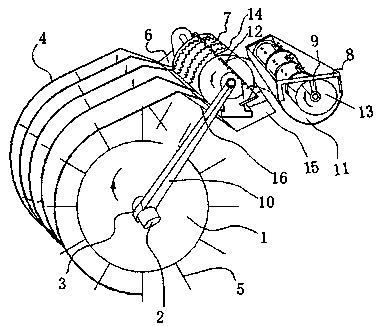

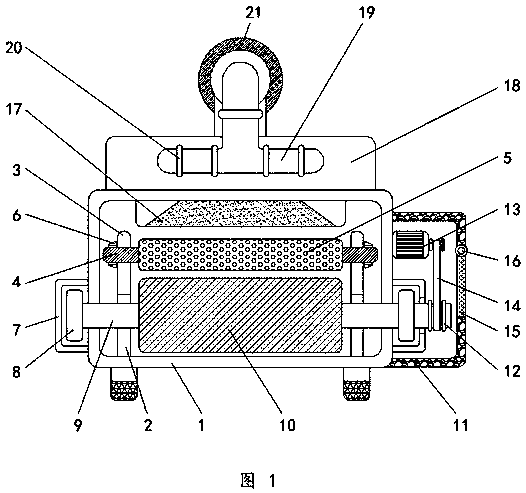

Automatic bale plucker

InactiveCN103422198AComb evenlySimple structureFibre breaking by beater armsEconomic benefitsEngineering

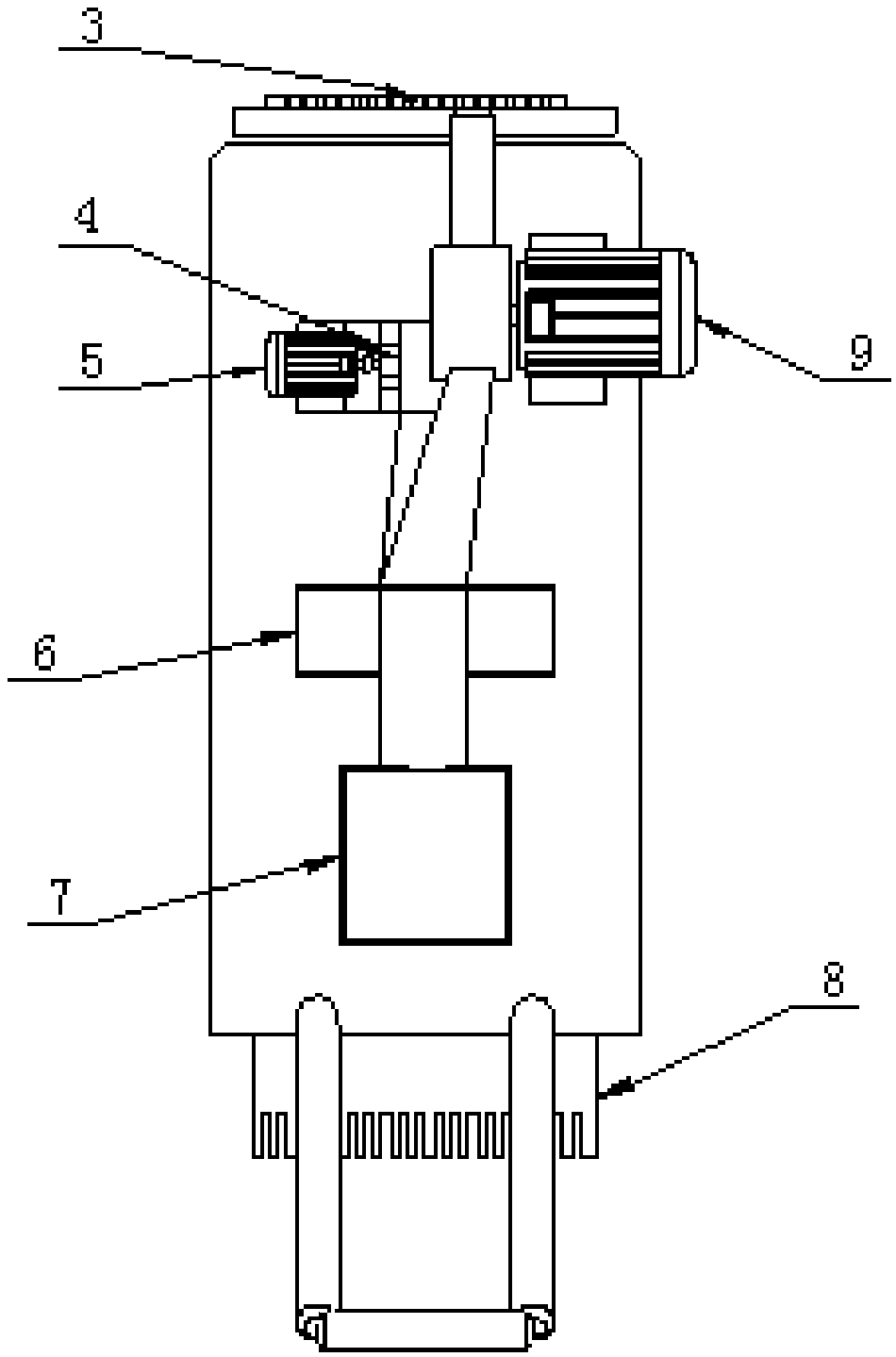

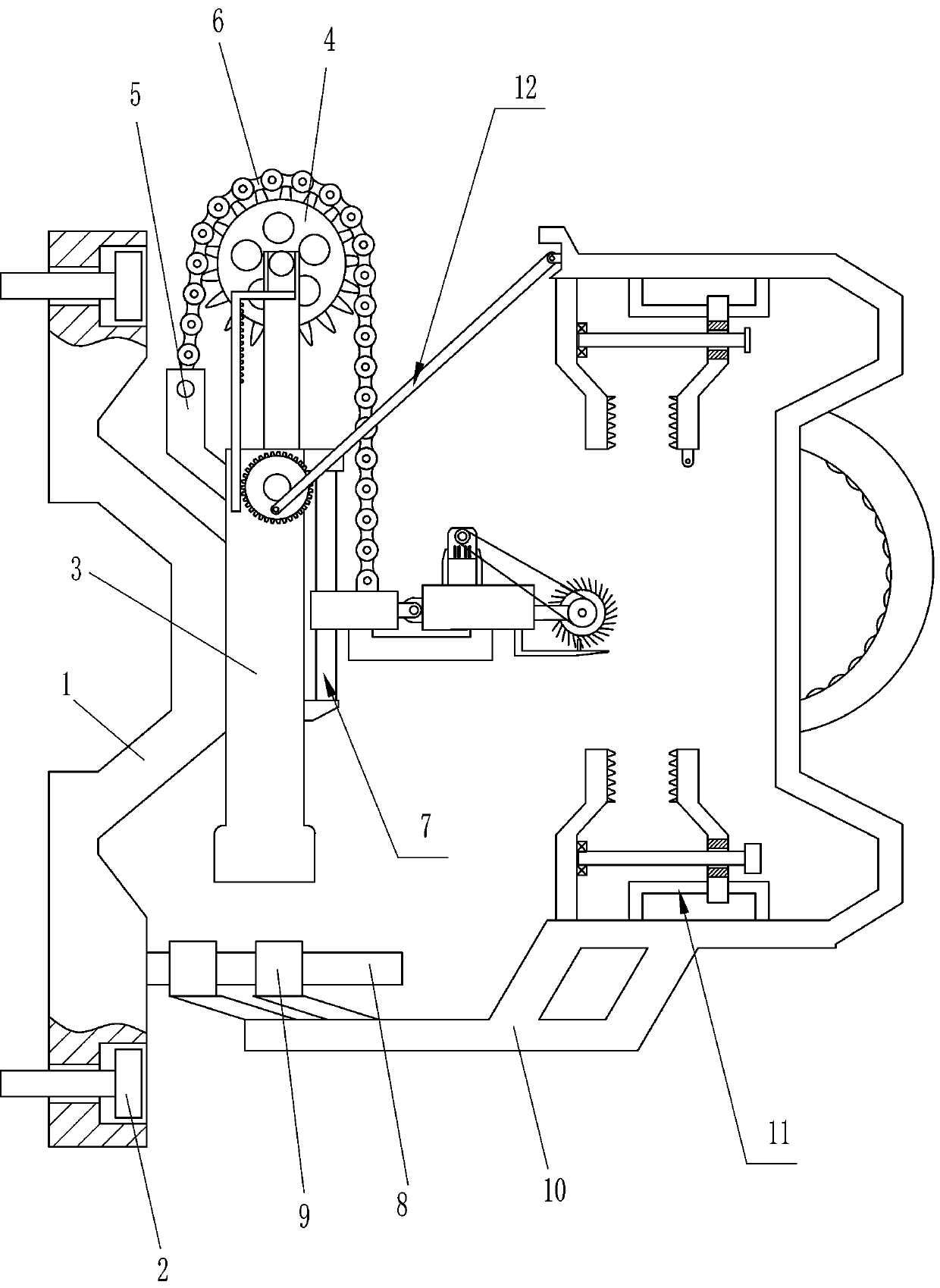

The invention discloses an automatic bale plucker which comprises an air suction hood and a driving device, wherein the driving device comprises a bale plucking arm, a power source and a center post, wherein the center post is fixedly arranged on a base; the power source is arranged inside the center post and drives the bale plucking arm to operate; a lifting device is arranged between the power source and the bale plucking arm; the air suction hood is fixedly arranged on the bale plucking arm; a bale plucking beater is arranged at the bottom of the air suction hood; blades are arranged at the periphery of the bale plucking beater; a cotton storage bin is arranged at the bottom of the air suction hood and is fixedly arranged on the base; a mobile cotton storage bin is also arranged on the base. The automatic bale plucker disclosed by the invention has the advantages of simple structure, simpleness and convenience in operation, reduced production cost, high bale plucking efficiency and low possibility of blocking; cotton raw materials are scutched to be more uniform, the working efficiency is increased and economic benefits are increased.

Owner:张志洲

High-grade crocodile leather oiling equipment moving with texture

ActiveCN110331235AEasy to processOil evenlySkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentPulp and paper industryBevel gear

The invention discloses high-grade crocodile leather oiling equipment moving with texture. The equipment comprises a machine body, wherein a moving cavity opening downward is formed in the machine body; a processing device which is used for conditioning the crocodile leather texture and oiling crocodile leather is arranged in the moving cavity; and a plug is rotated firstly, maintenance oil is added into an oil tank, and then a power motor is started, so that a power shaft, a long sliding key and a third bevel gear are driven to rotate. Compared with processing equipment of other leather materials, the high-grade crocodile leather oiling equipment is more suitable for combing the texture of the crocodile leather and oiling the crocodile leather; and combing the crocodile leather texture and oiling the crocodile leather are achieved through a heatable roller, so that each piece of the leather is uniformly oiled and combed, and it is convenient for people to process the crocodile leatherinto leather bags, leather shoes and the like.

Owner:江苏世丰企业管理咨询有限公司

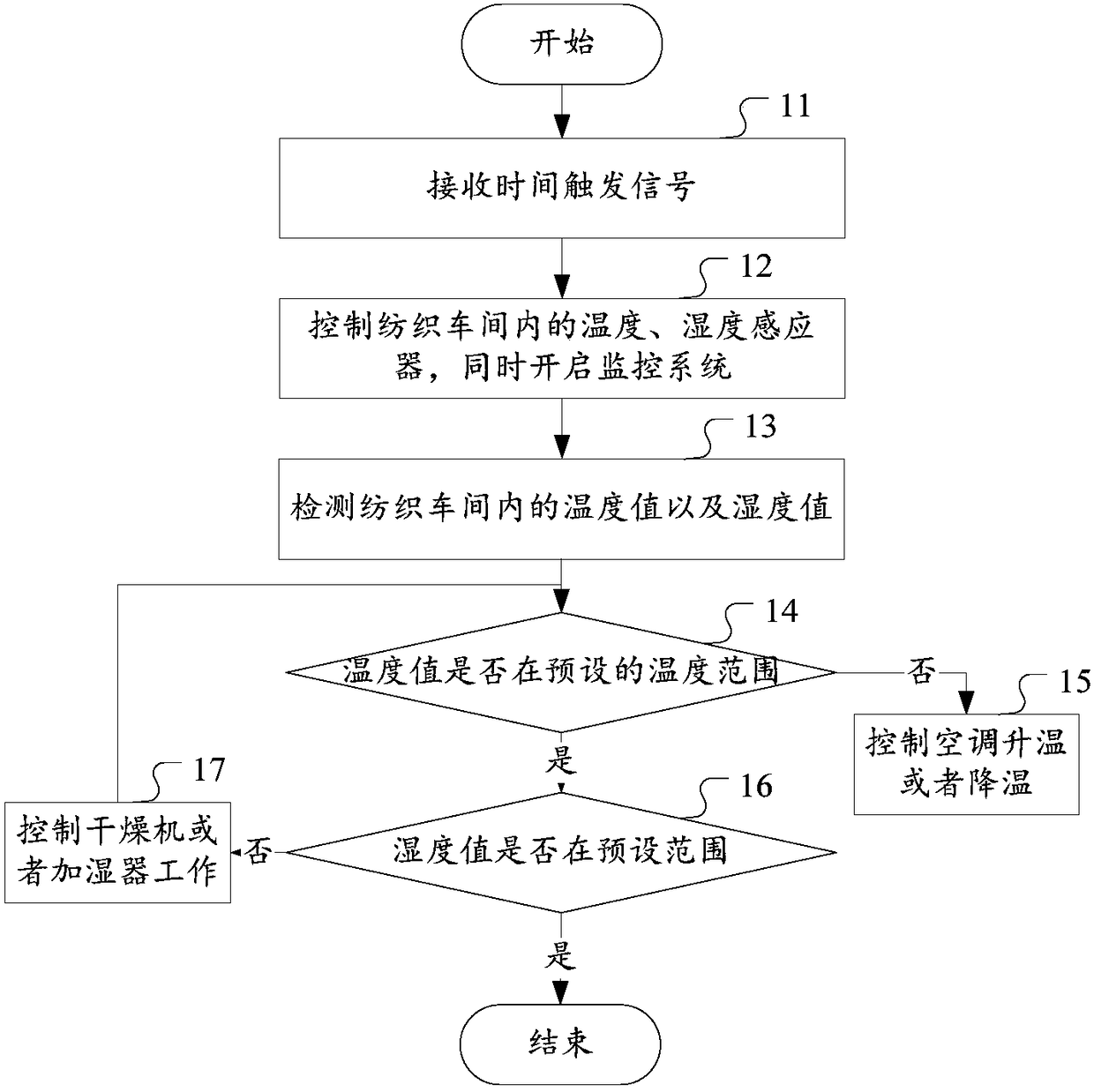

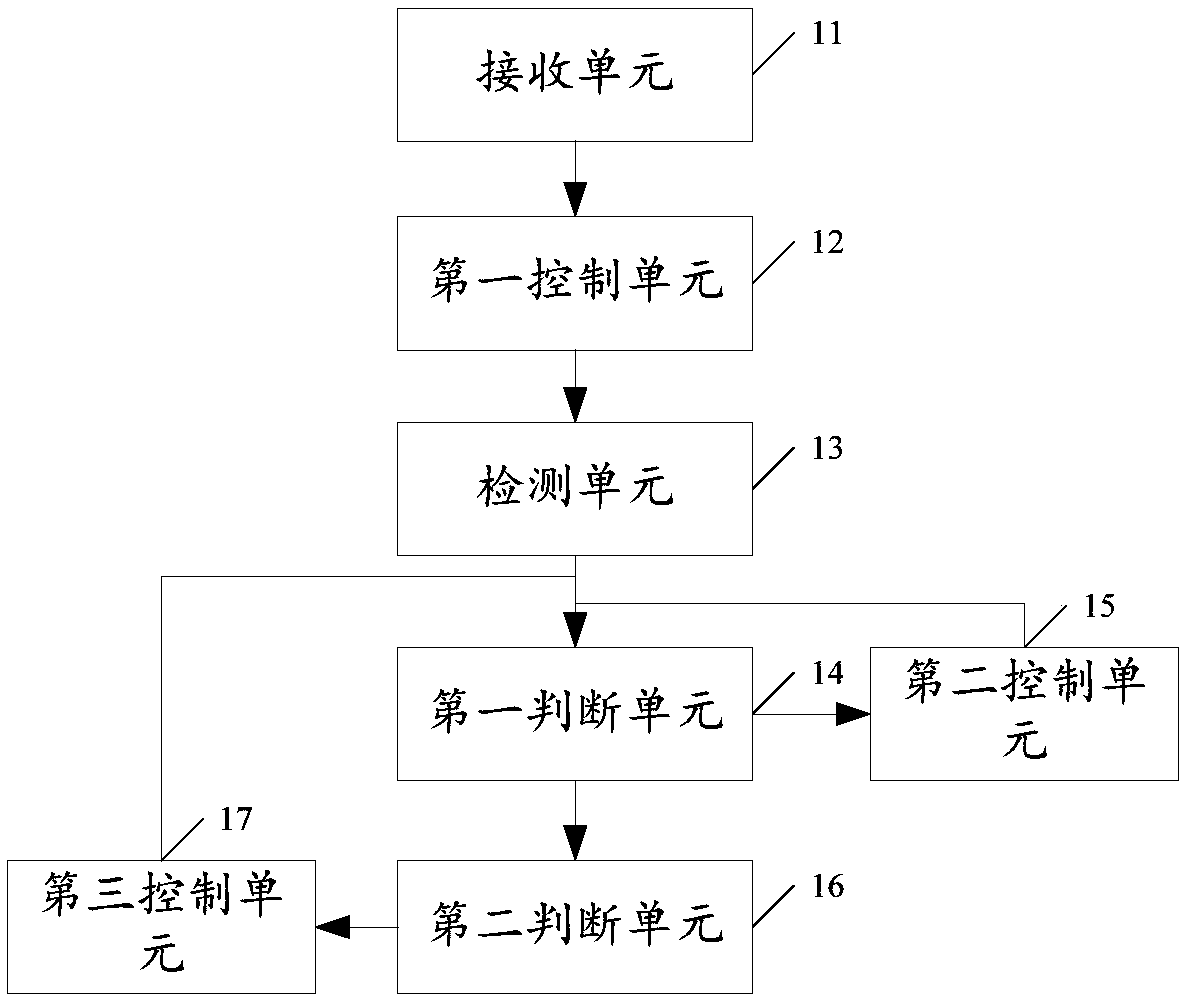

Constant-temperature and constant-humidity control method for textile workshop

InactiveCN108548295AReal-time monitoringQuality assuranceMechanical apparatusLighting and heating apparatusYarnFiber

The invention discloses a constant-temperature and constant-humidity control method for a textile workshop. The constant-temperature and constant-humidity control method comprises the steps of receiving a time trigger signal; controlling a temperature and humidity sensor and a monitor system in the textile workshop to work; detecting the temperature value and the humidity value in the textile workshop; judging whether the temperature value is within the preset temperature range or not; and if yes, judging whether the humidity value is within the preset range or not. By means of the constant-temperature and constant-humidity control method for the textile workshop, it can be ensured that at the non-working time after working hours, the textile workshop also keeps the constant-temperature and constant-humidity environment, the quality of semi-finished textile products is ensured, the spinning strength is enhanced in the spinning process, the end breakage rate is decreased, burrs in the working environment are reduced, static electricity is reduced, fiber stretching, carding, spinning and the like can be smoothly carried out, the yield and quality are improved, manpower and material resources are saved, and meanwhile, the condition of the textile workshop can be monitored in real time.

Owner:FOSHAN GUILI CLOTHING MATERIALS CO LTD

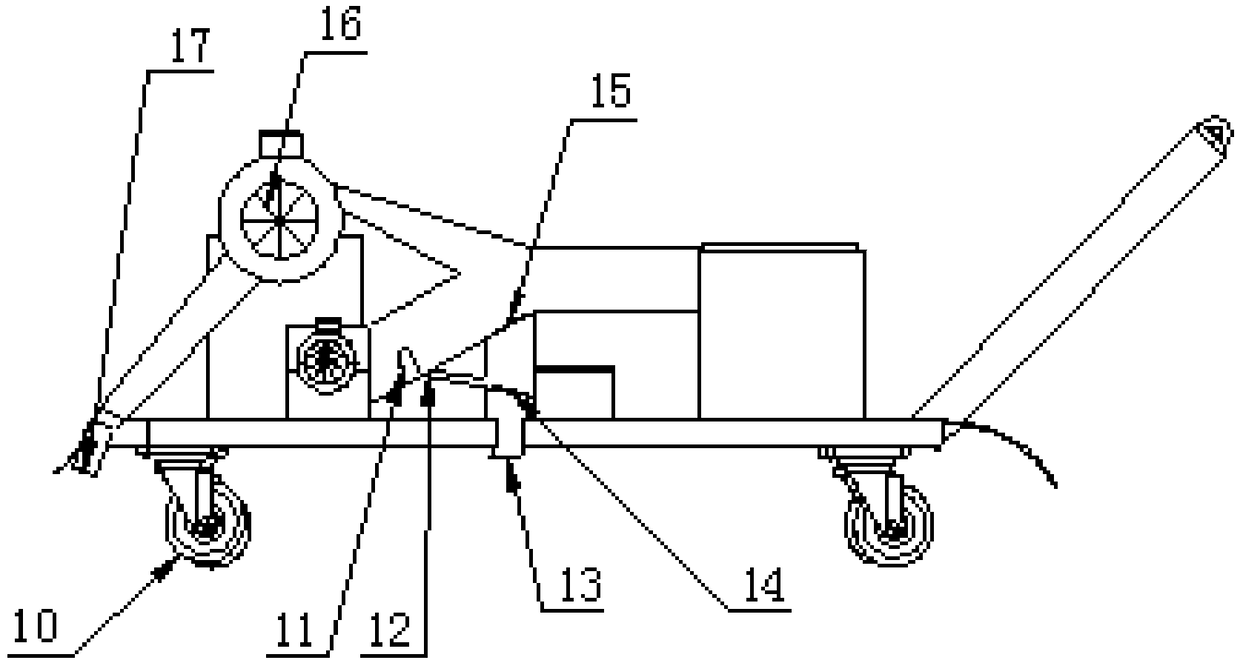

Device used for cleaning artificial turfs

InactiveCN108824310AImprove conversion efficiencyMature technologyRoad cleaningImpellerArtificial turf

The invention discloses a device used for cleaning artificial turfs. A front grass combing device separates small trash in an artificial turf from grass; a second direct current motor works and drivesan impeller to rotate, so the trash enters a second passage through a suction inlet and a first passage; a first direct current motor is utilized to drive fan blades to rotate, airflow is generated to conduct one-time separation on the trash in the second passage, and lighter trash is separated to enter a first trash storage box; the rest trash is subjected to secondary separation, and most of rubber particles in the trash directly enter into a releasing opening through a first screening net and a second screening net; the rubber particles entering into the releasing opening return to the turf, and a worker pushes the trolley body to drive a back grass combing device for uniform combing. The problems in the prior art that manually cleaning the artificial turf wastes time and energy, and the manual mode is not suitable for the cleaning of large-area artificial turfs are solved. The device can improve the efficiency of cleaning away the trash on the artificial turfs and be suitable forthe cleaning of the large-area artificial turfs.

Owner:YULIN UNIV

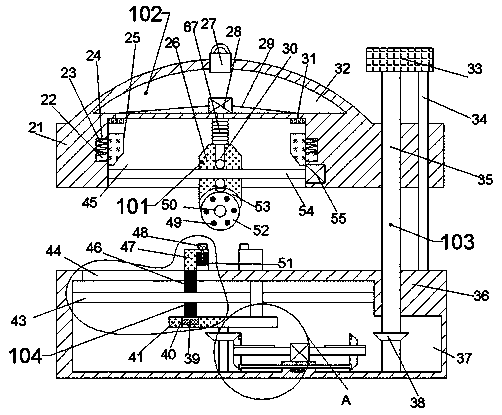

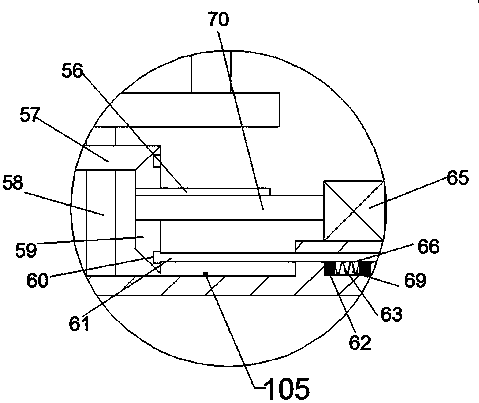

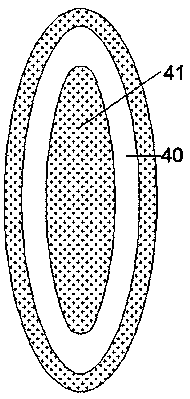

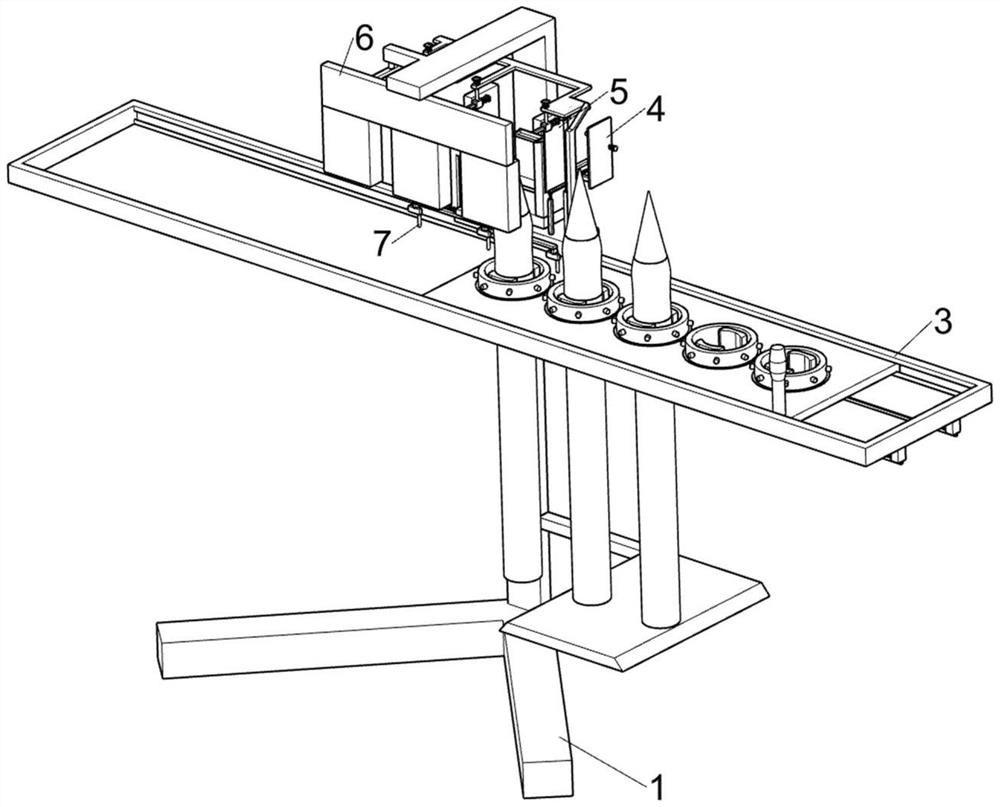

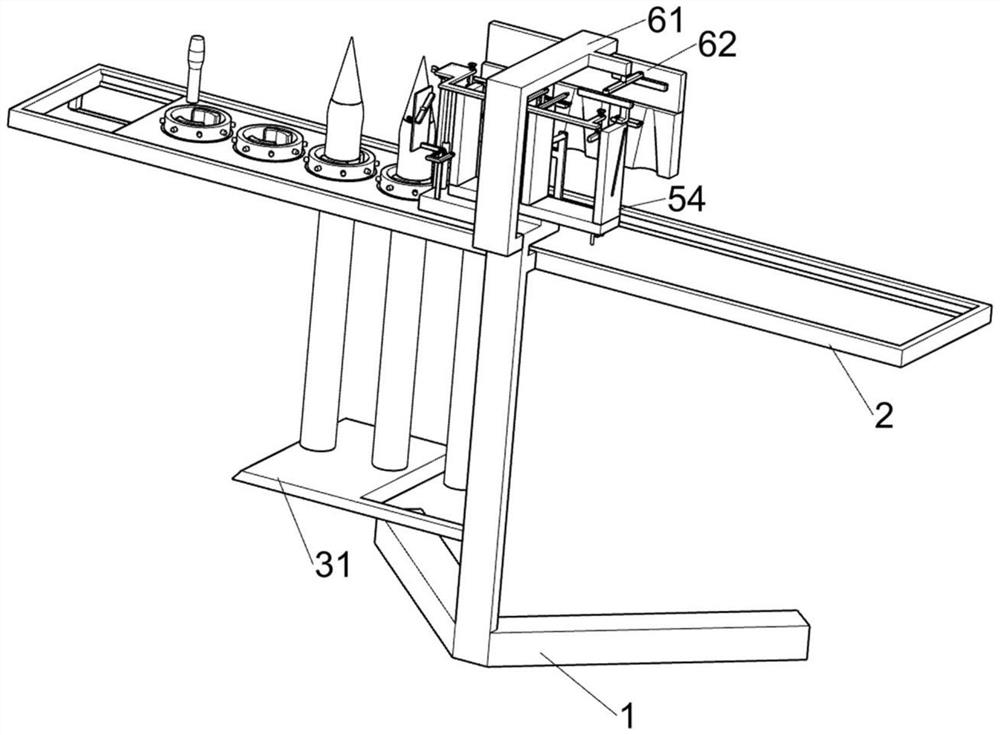

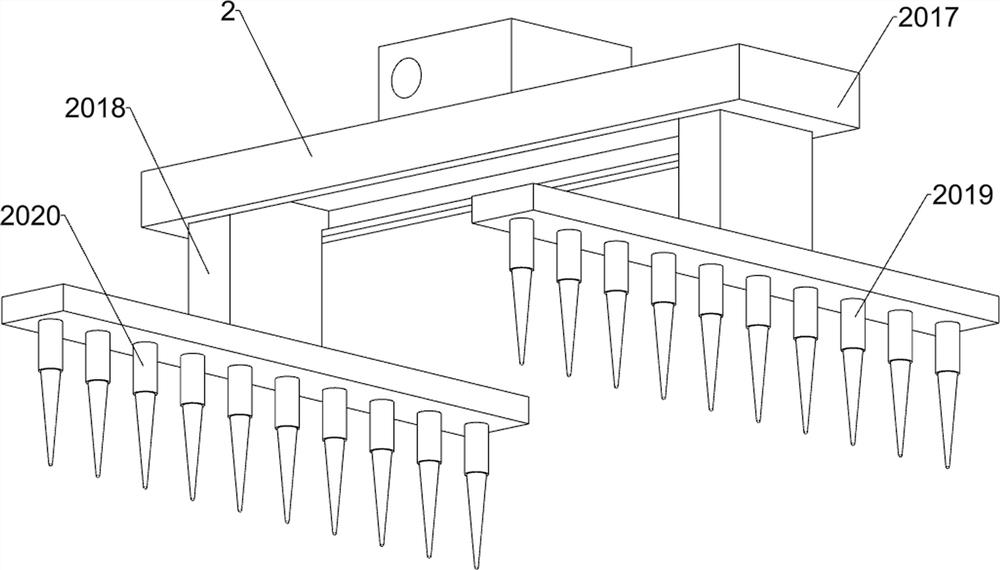

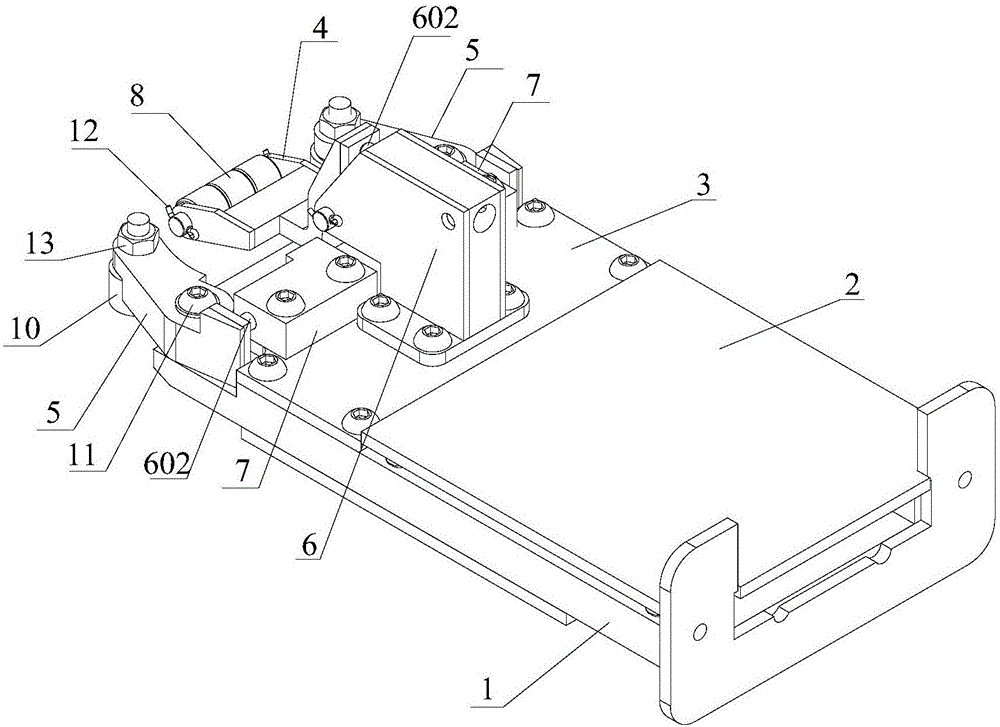

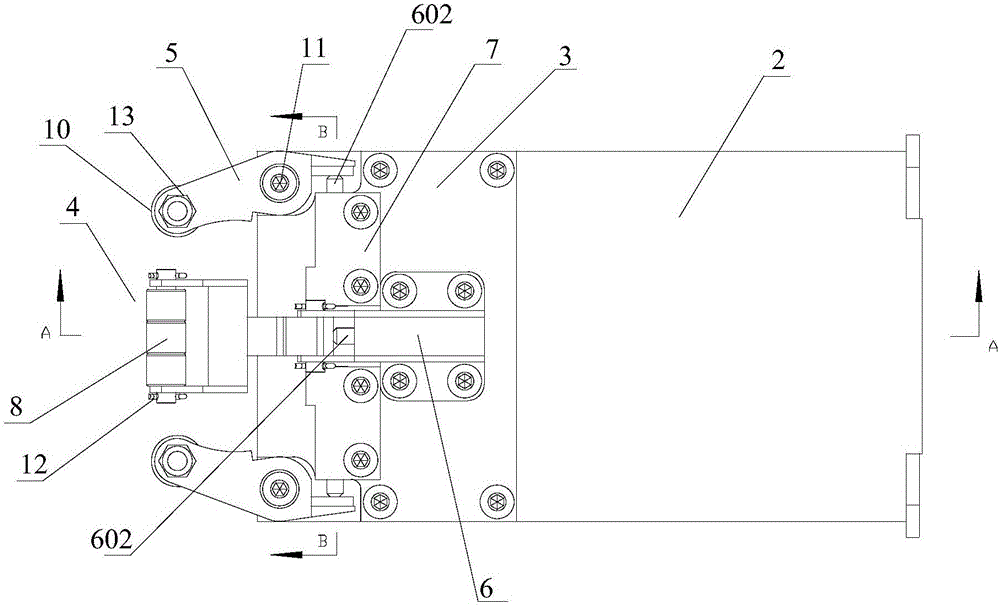

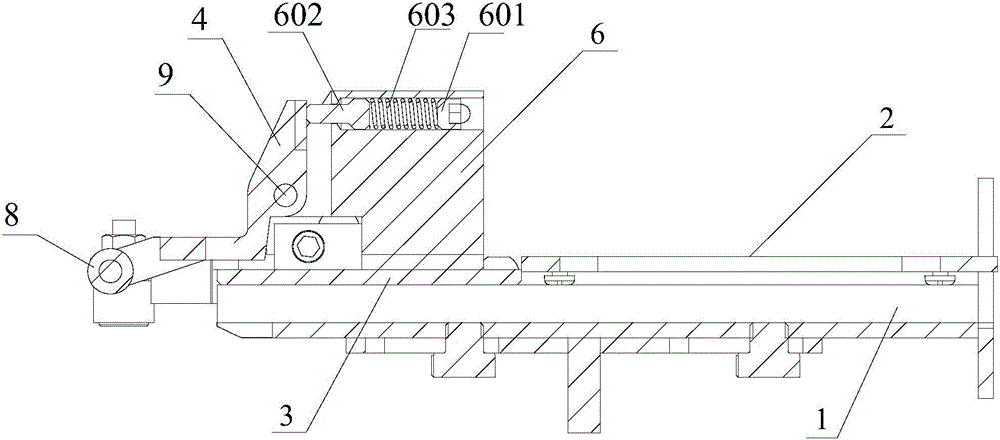

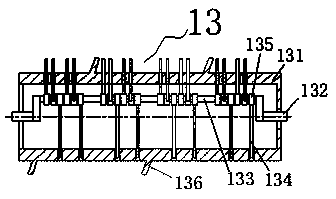

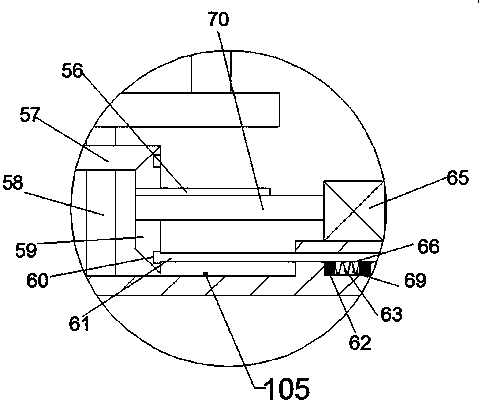

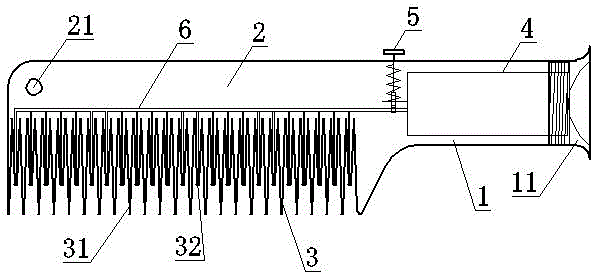

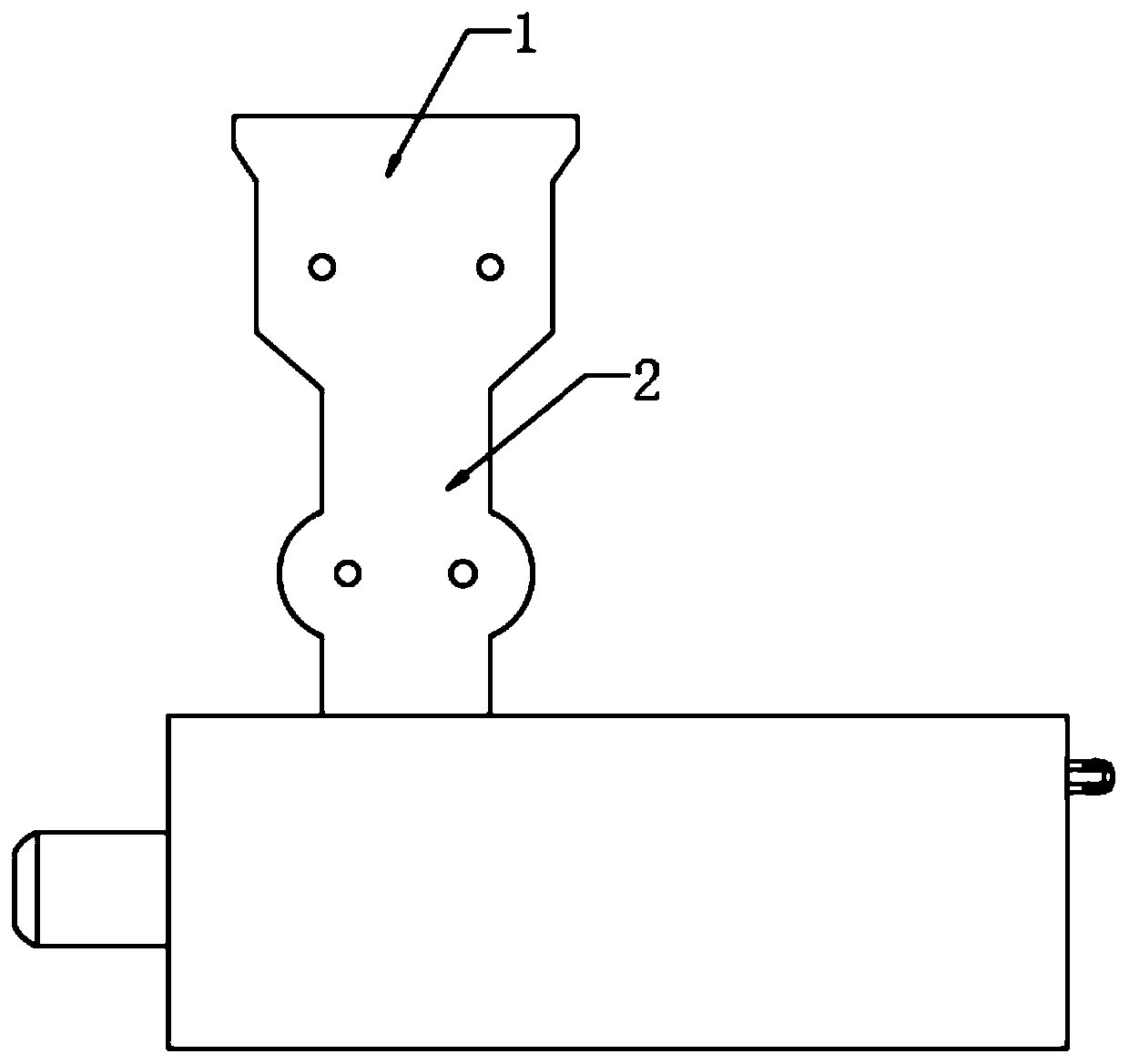

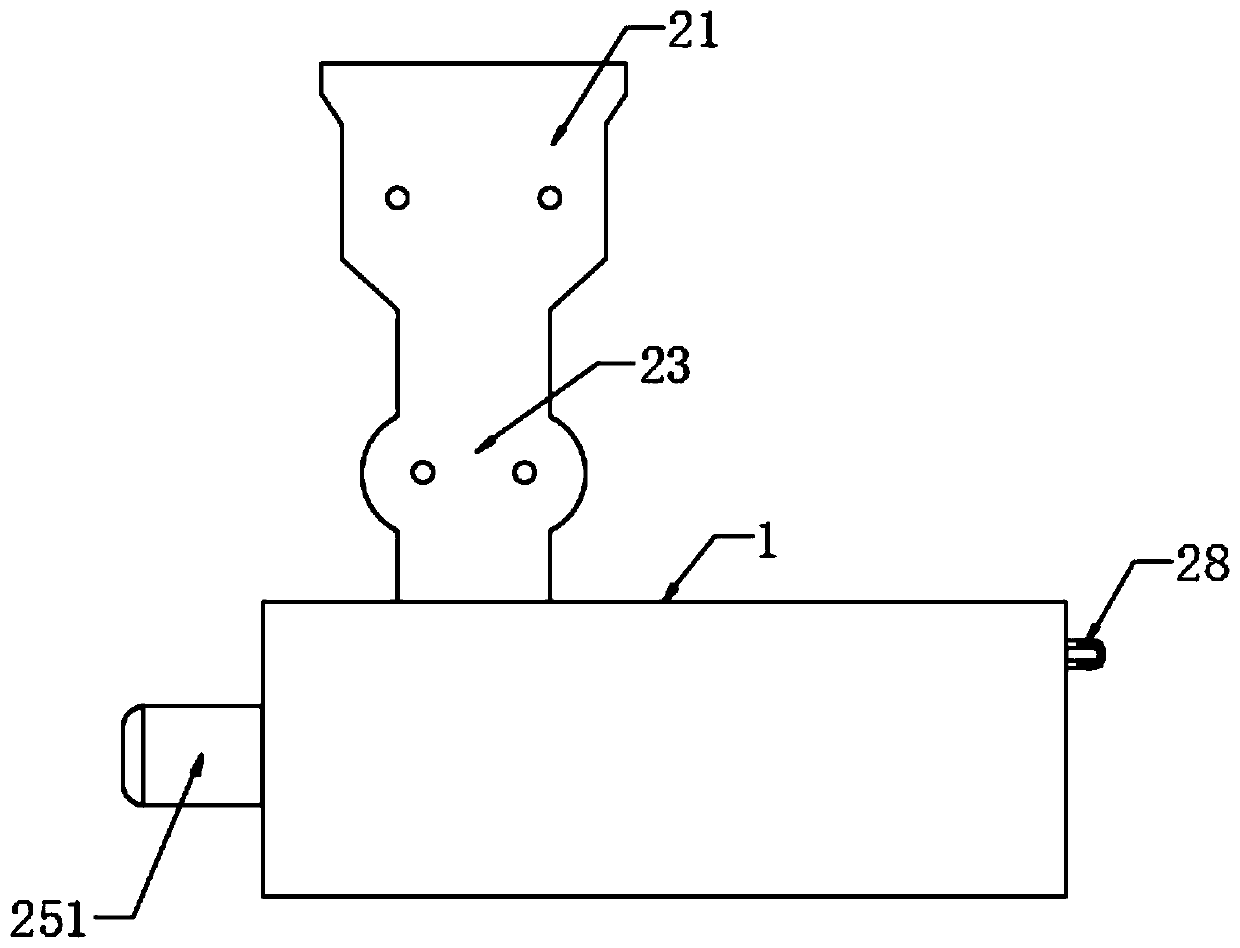

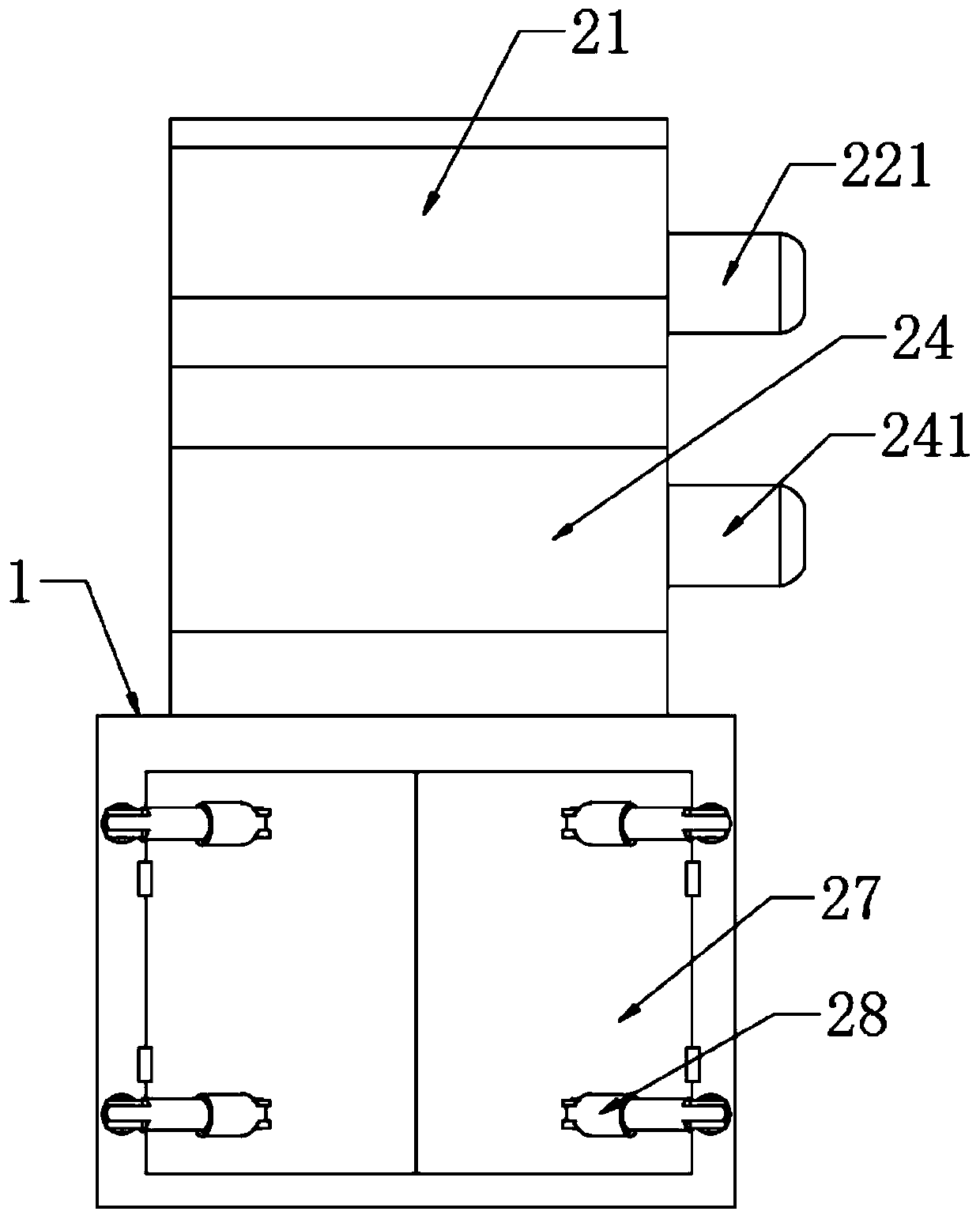

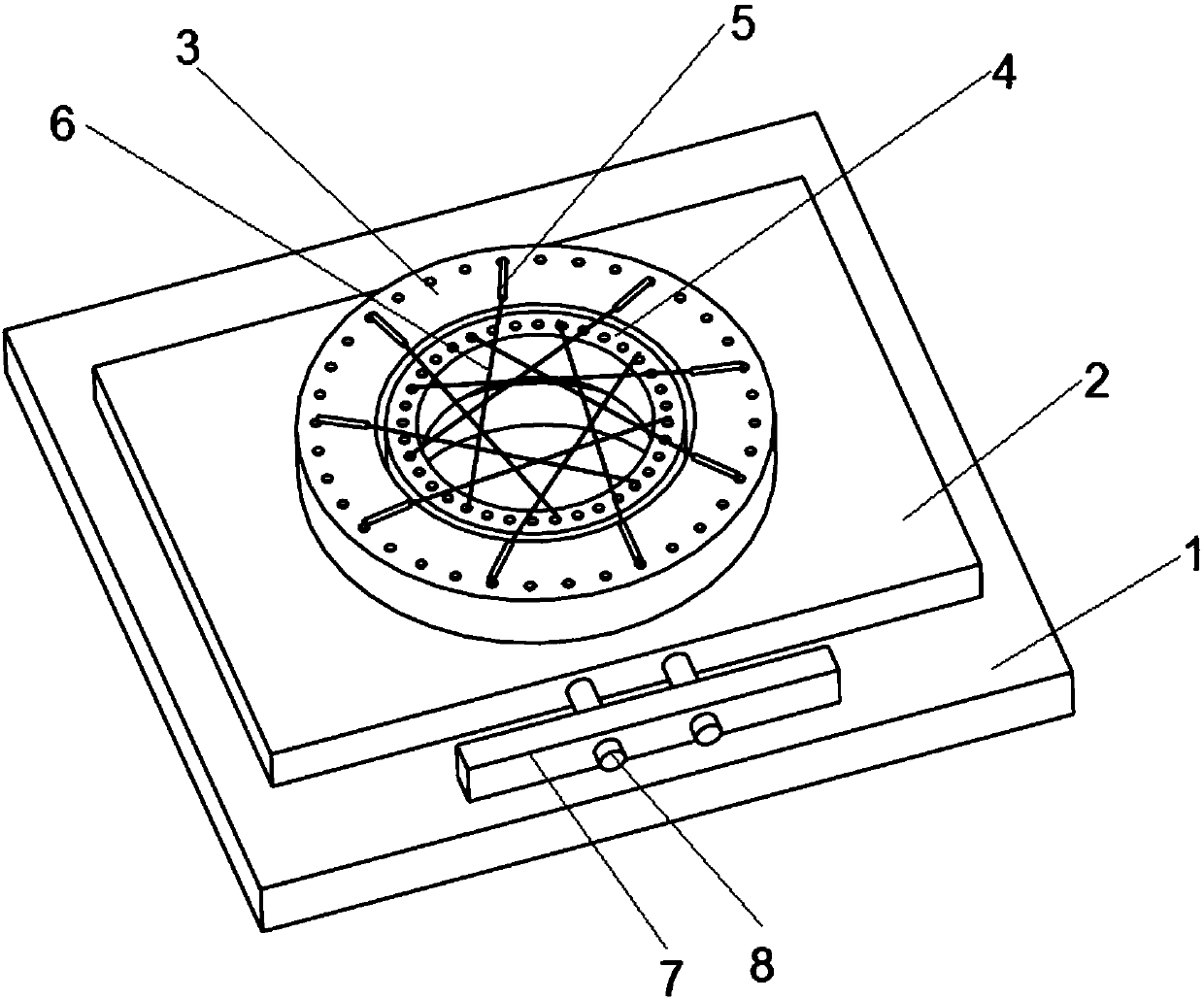

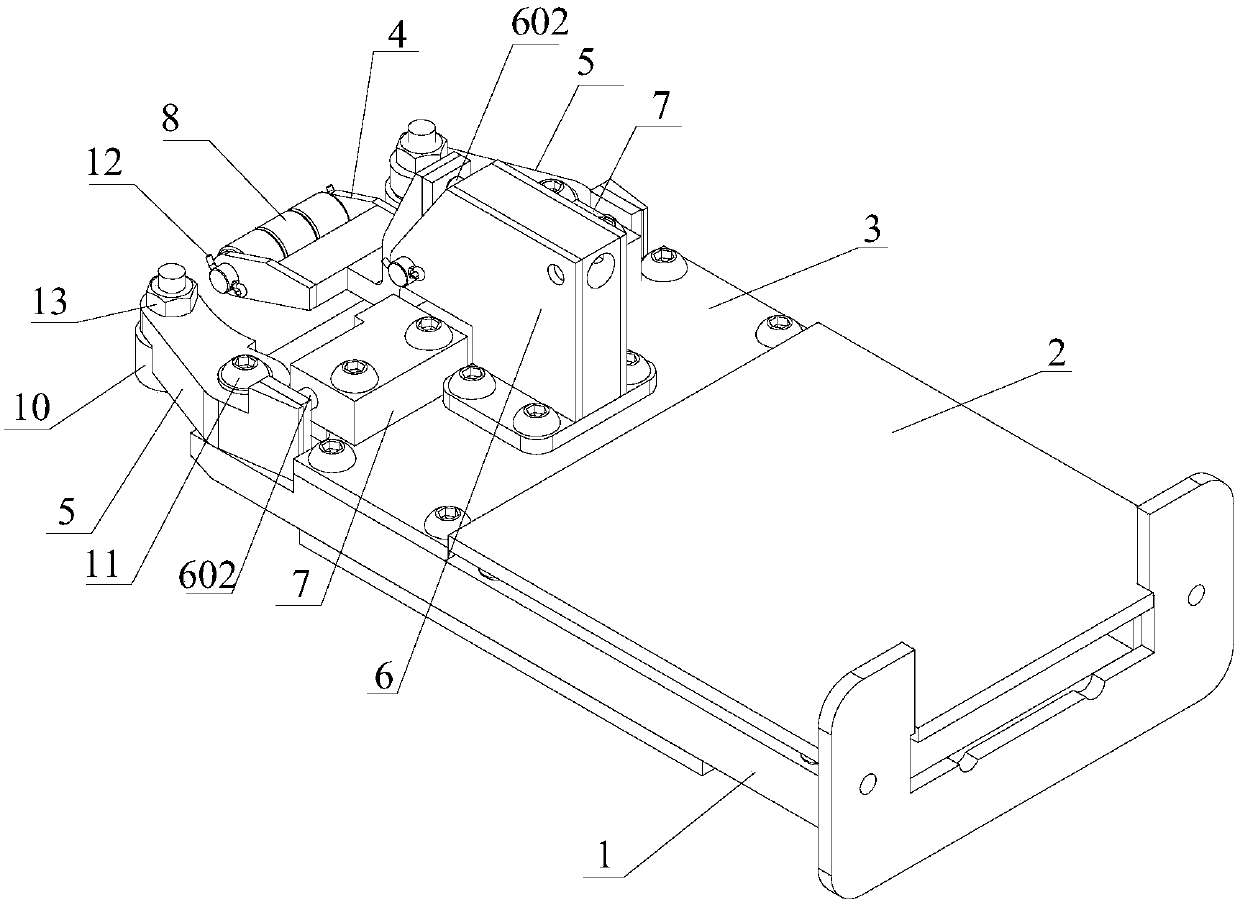

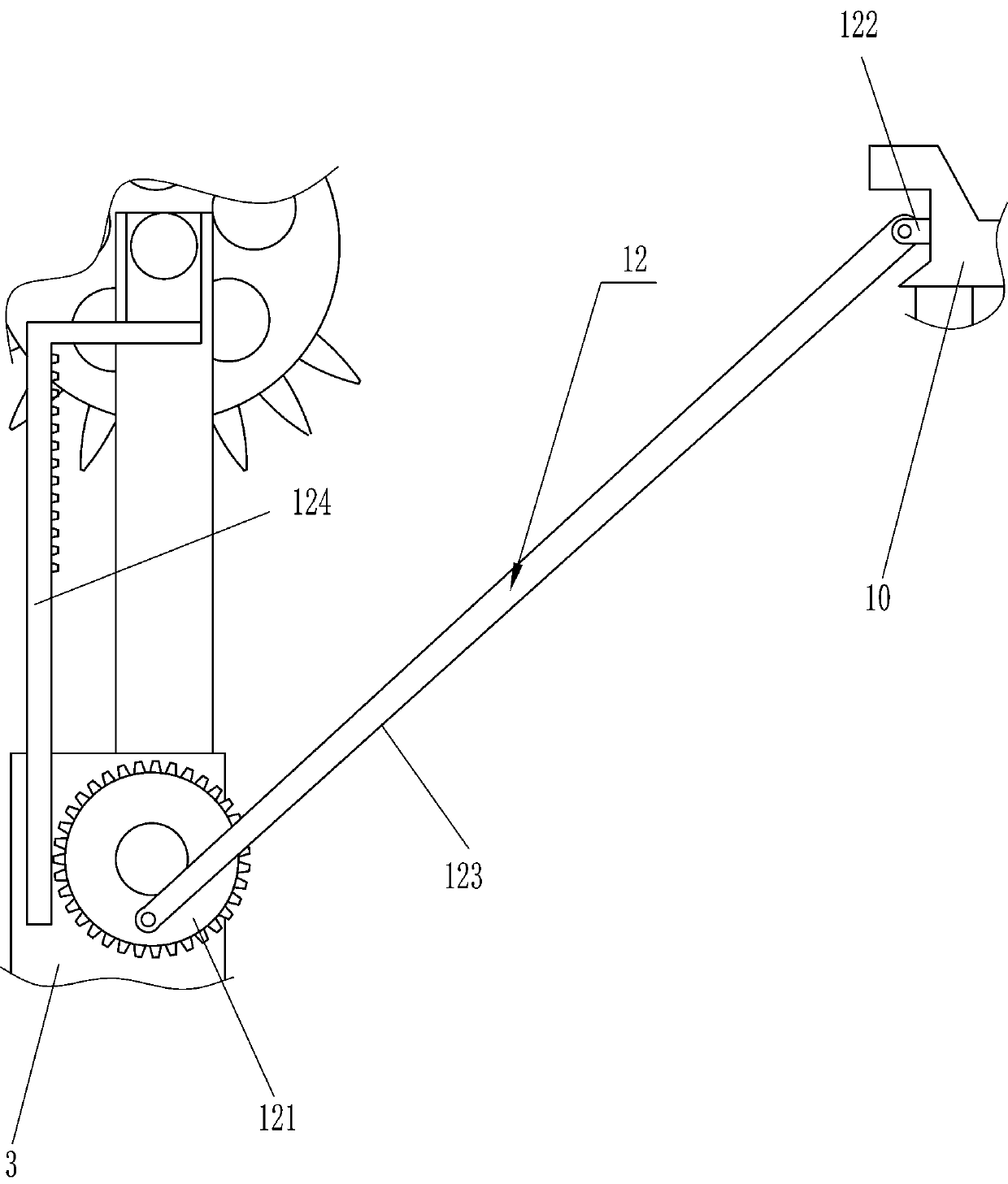

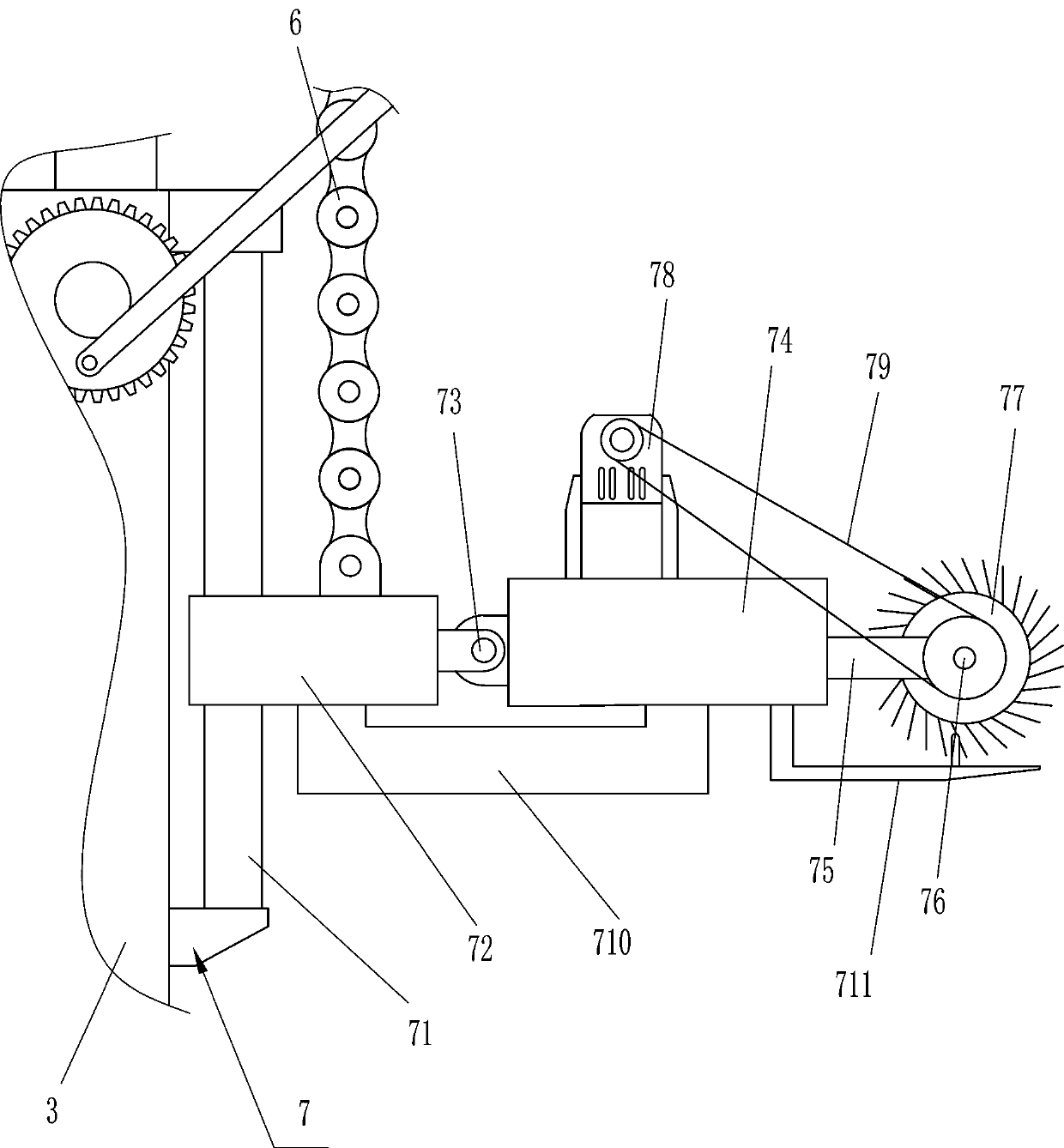

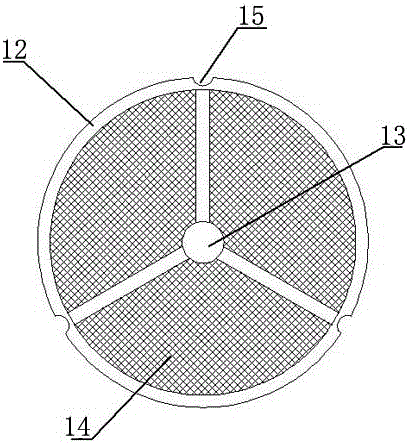

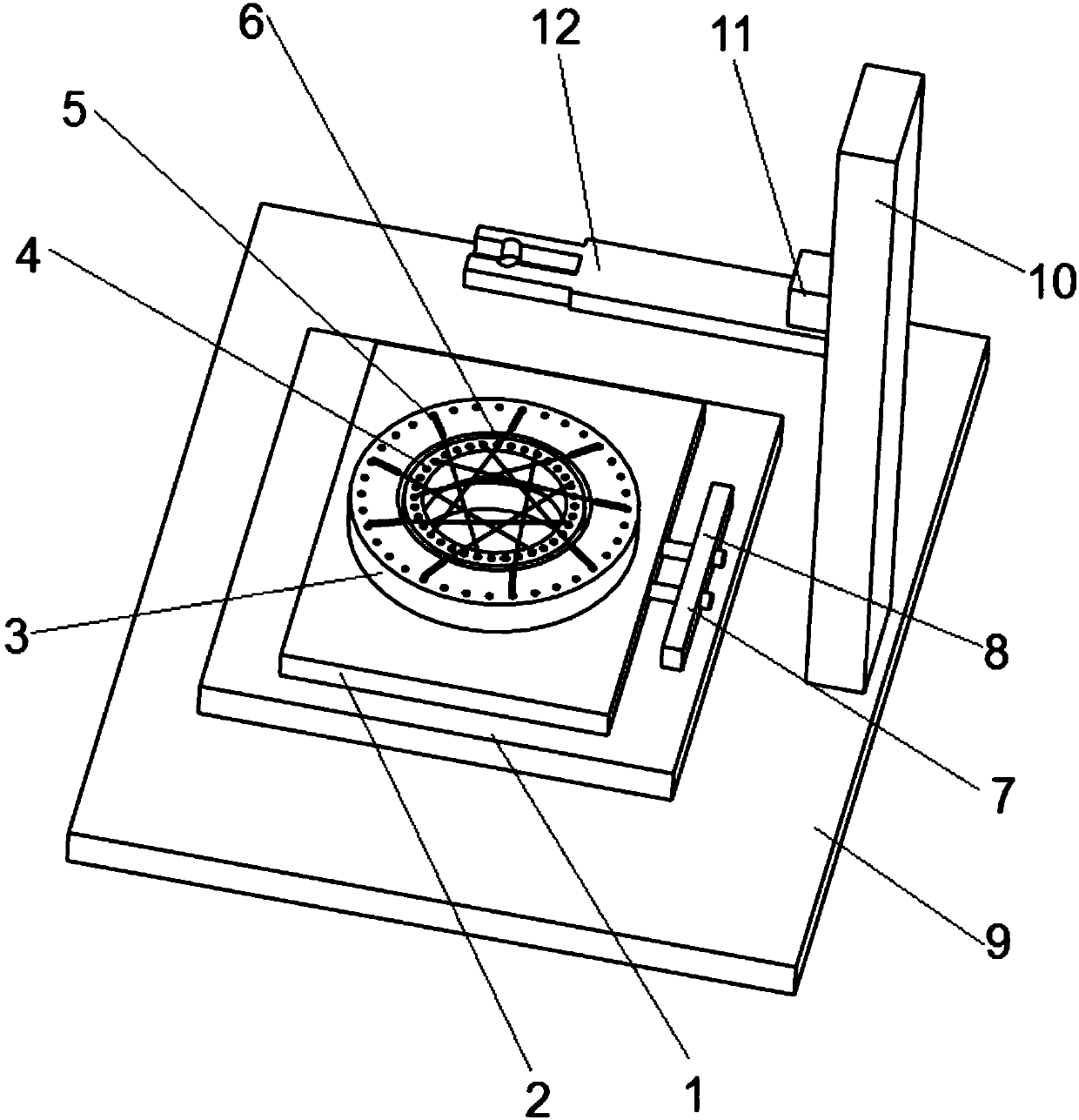

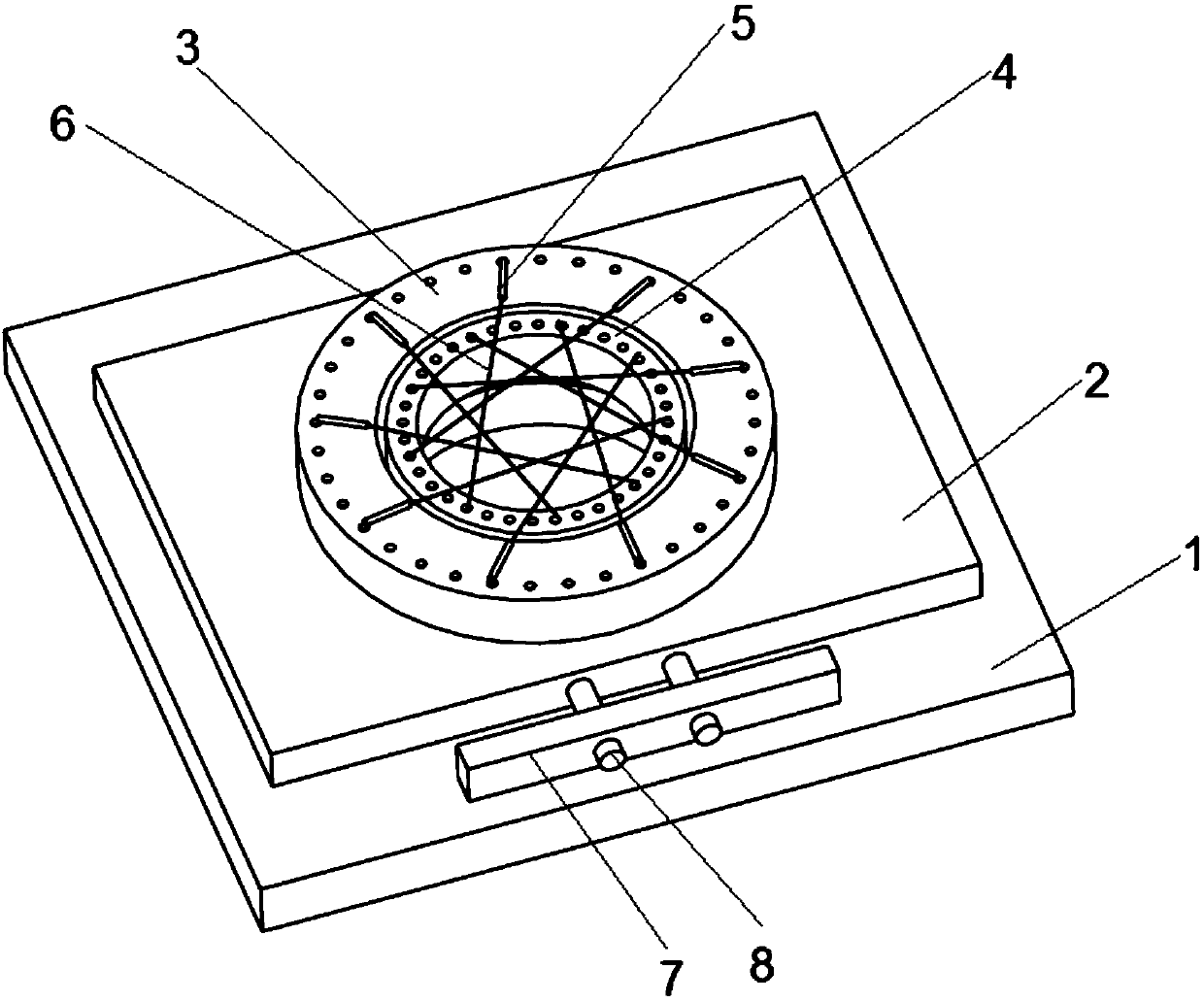

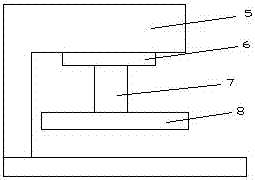

Pen point combing robot feeding mechanism

ActiveCN106166909APlay the role of squeezing the tip of the penImprove carding efficiencyPen repairingNibsEngineeringMechanical engineering

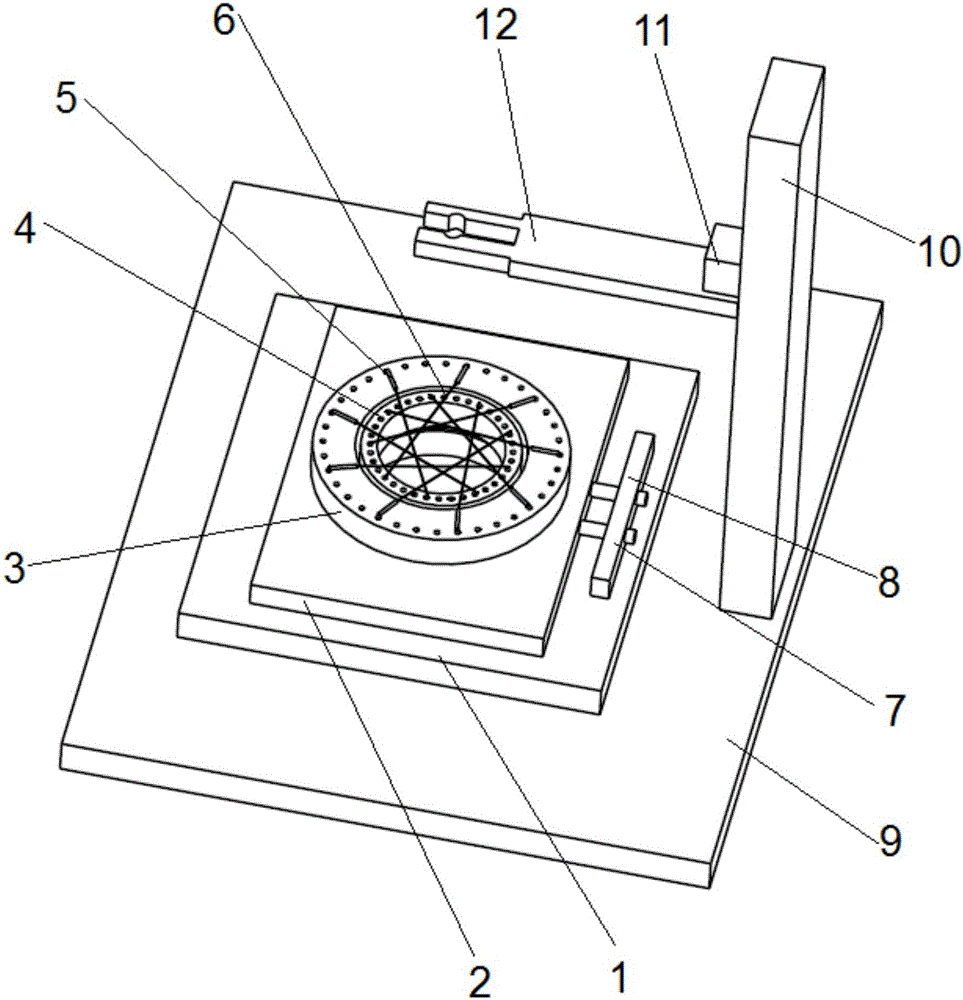

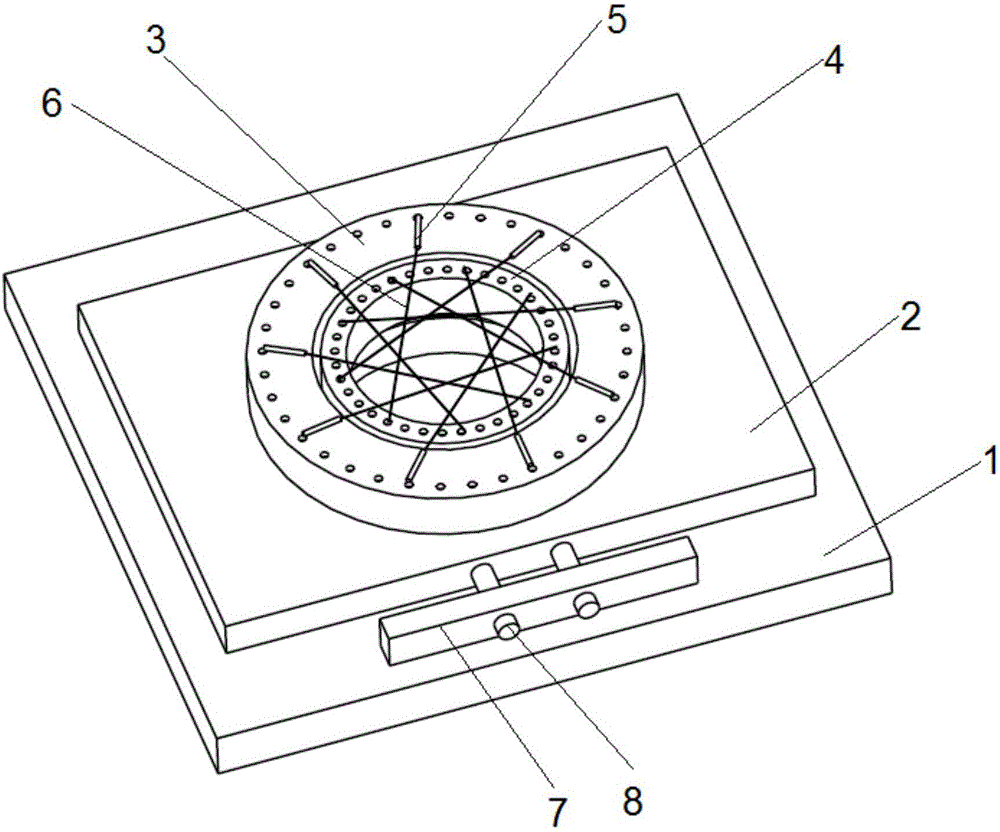

The invention discloses a pen point combing robot feeding mechanism which comprises a fixed disc, a rotary disc, at least three sets of combing belts and a conveying mechanism. The rotary disc is arranged in the middle of the fixed disc and can be rotated. Each set of combing belt comprises a spring and a rope, wherein one end of the spring is connected with one end of the rope, the other two ends are connected to the fixed disc and the rotary disc respectively, the three sets of combing belts are distributed at different positions on the periphery of the fixed disc, the conveying mechanism comprises a stand column, a sliding base capable of sliding up and down on the stand column and a clamping jaw arranged on the sliding base and capable of clamping a pen. The pen point combing robot feeding mechanism automatically combs a pen point, and is high in combing efficiency and uniform in combing.

Owner:ANHUI ZHONG XIN MOLD IND DEV CO LTD

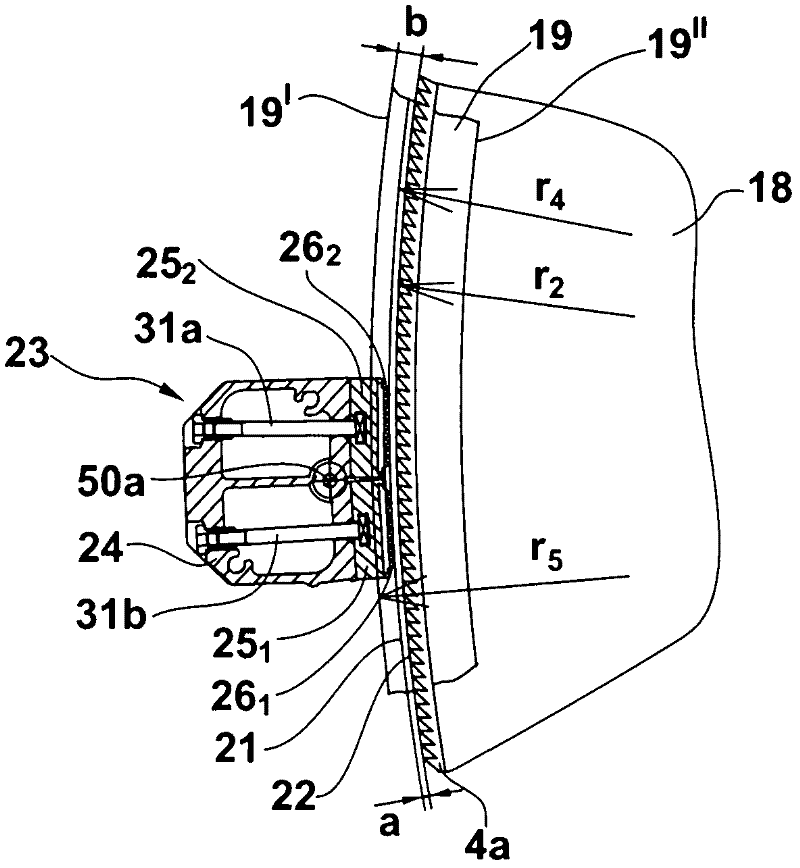

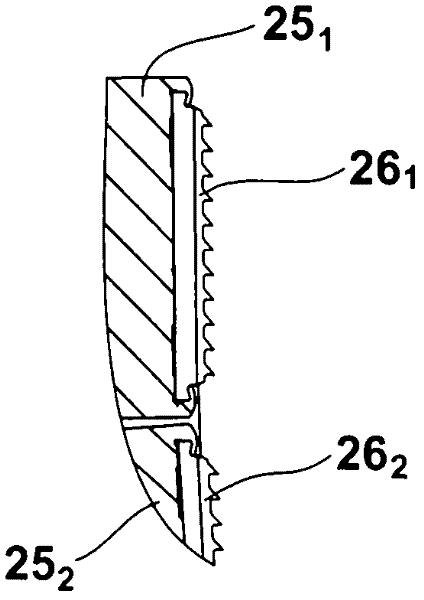

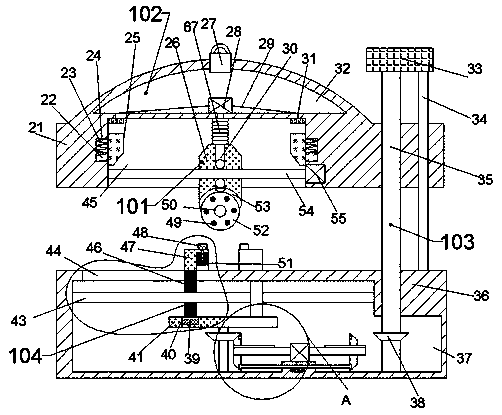

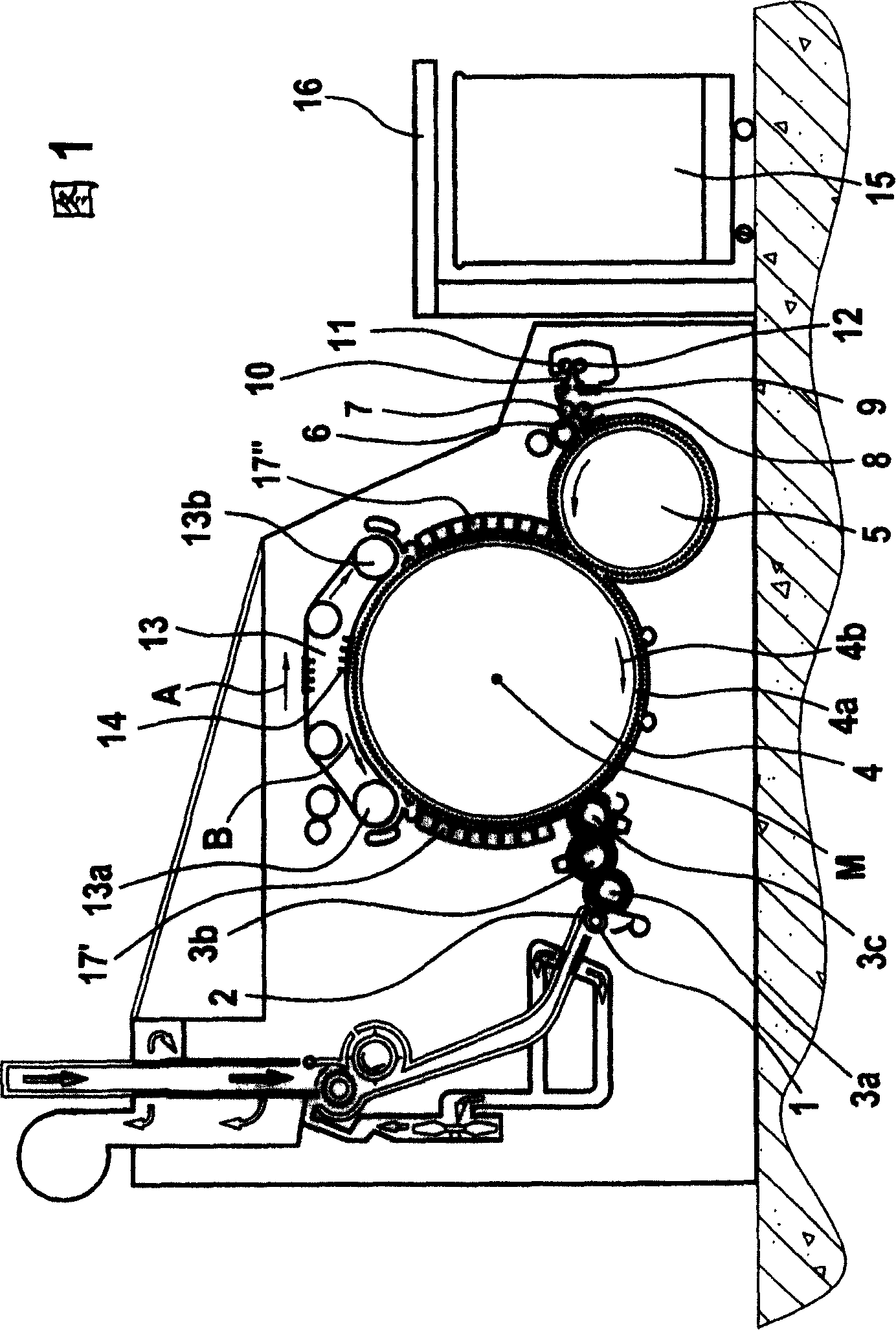

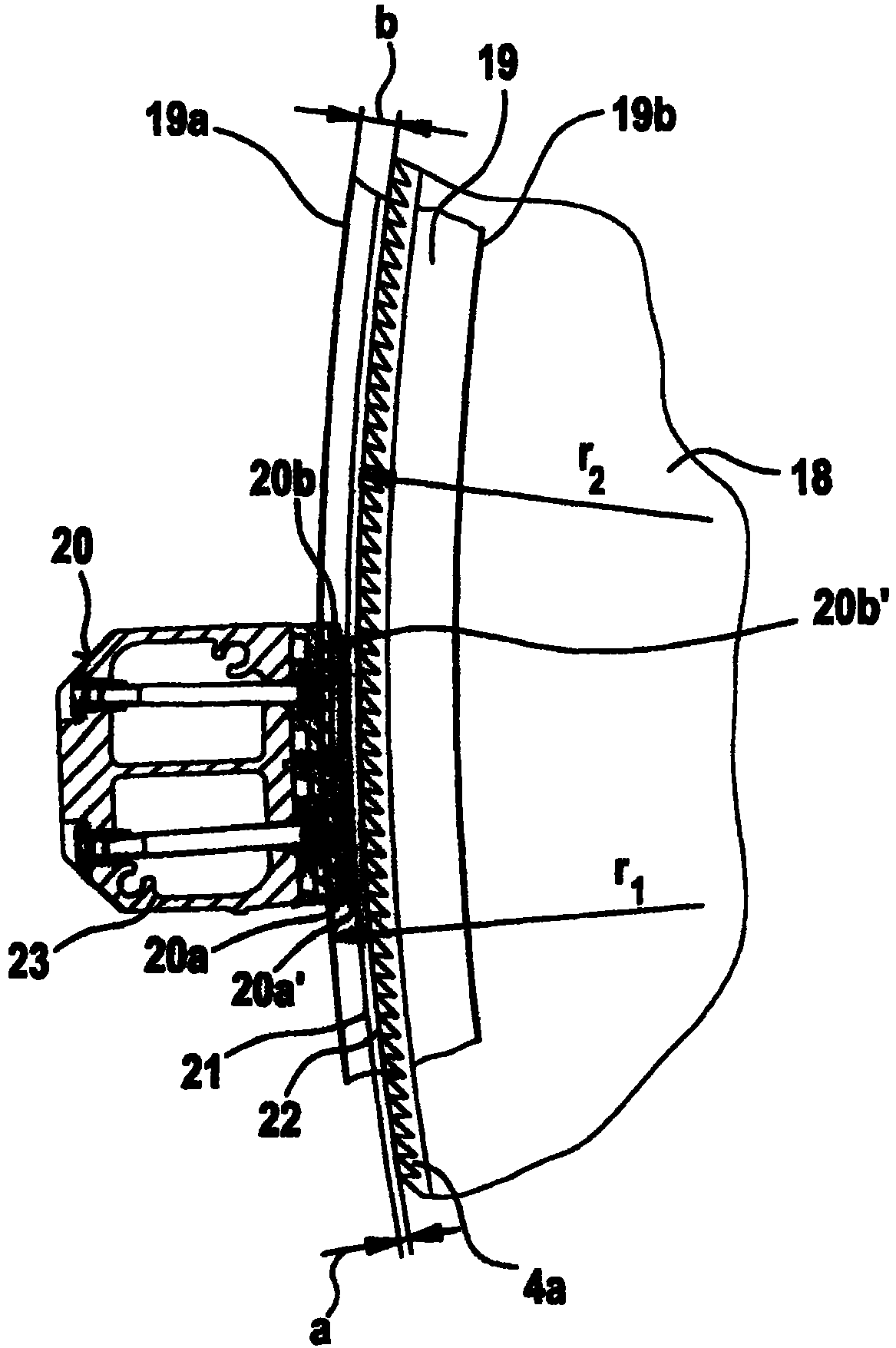

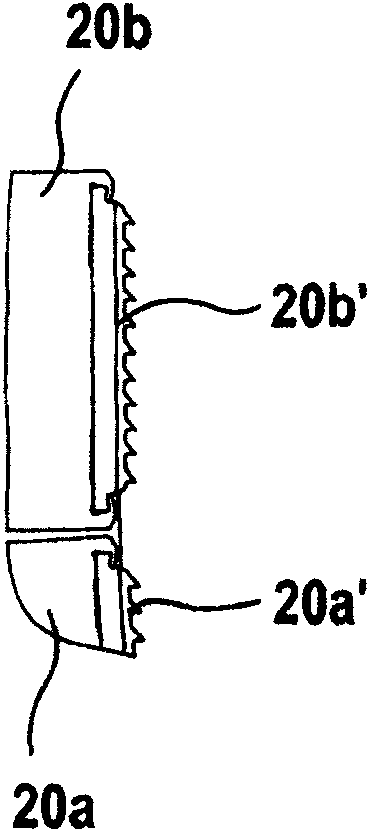

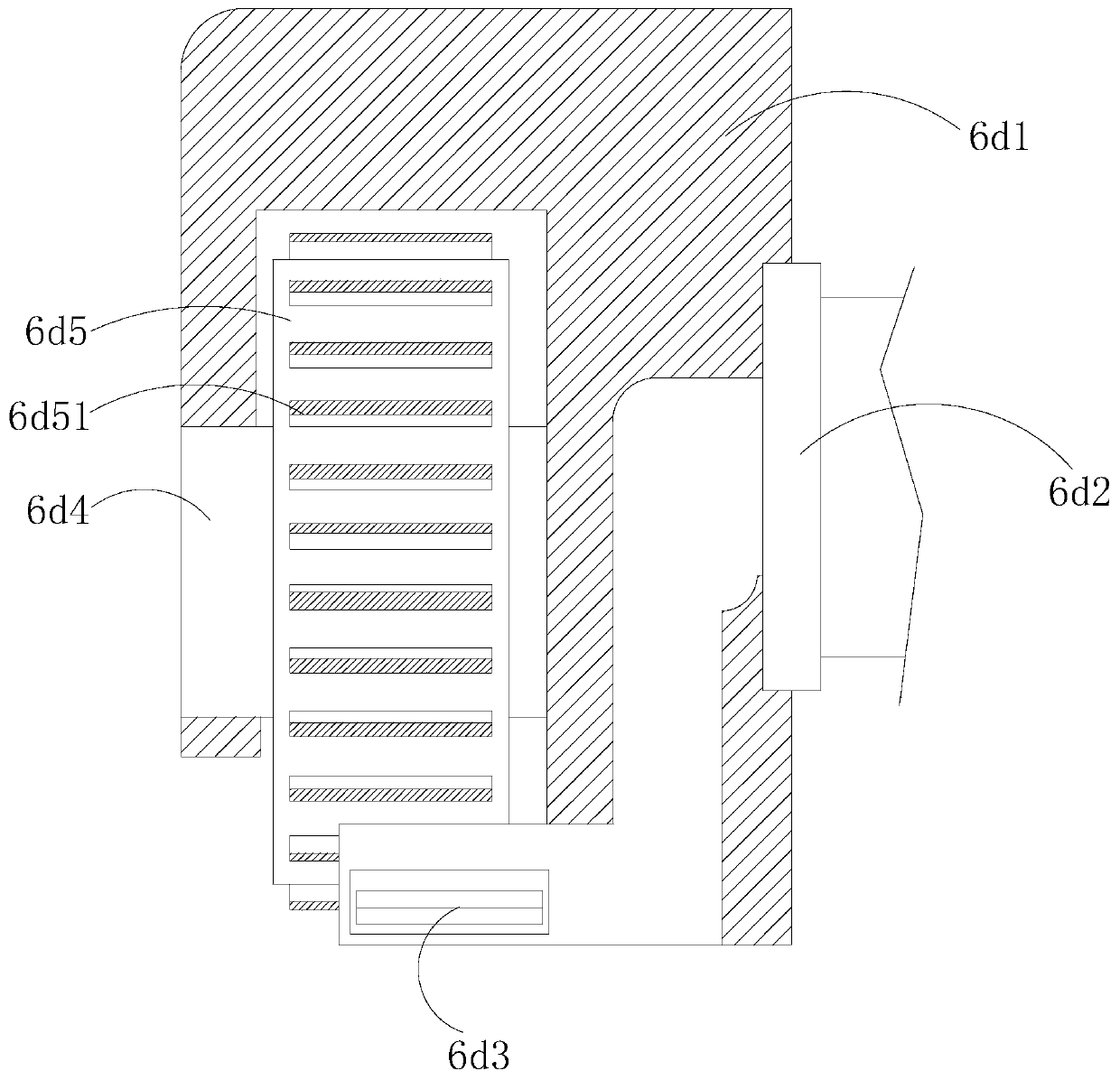

Carding machine carrier element with tensioning element

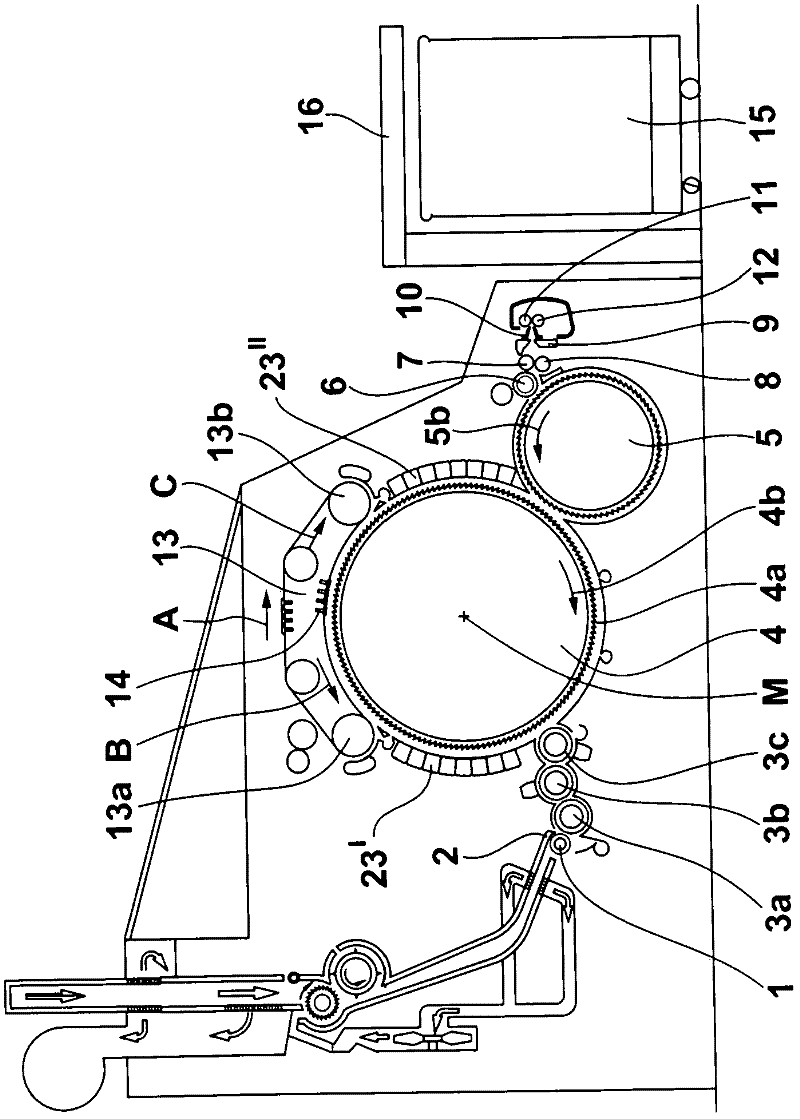

ActiveCN102560751AFirmly connectedCompensation for convex expansionCarding machinesFiberThermal expansion

A flat or roller card comprises is at least one working element and / or functional element, for example a fixed carding element or revolving flat bar with an elongate carrier element 24. A tensioning element 51 associated with the carrier element allows adjustment of the working element to enable the carding nip to be constant. A clamping device 50 is provided with which the position of the tensioning element 51 is fixable with respect to the carrier element 24. The clamping device may be used to pre-tension the working element such that an operational temperature differential causes the working element to bow in a complimentary manner to the associated working cylinder. Alternatively the clamping element may be activated in use by an increasing temperature differential. Preferably a steel rod 51 is located inside an aluminium tube 52 which is in-turn located within a recess of the carrier element with insulation between the tube and carrier element. The clamping device preferably comprises a sleeve nut threaded onto the aluminium tube and has claws with chamfered surfaces such that screwing the nut onto the tube or relative thermal expansion of the tube and carrier element causes the claws to clamp onto the rod 51.

Owner:TRUETZSCHLER GRP SE

Reciprocating glue solution cleaning device for writing brush gluing

The invention relates to the field of writing brush processing, and particularly relates to a reciprocating glue solution cleaning device for writing brush gluing. The reciprocating glue solution cleaning device comprises a first supporting frame, a sliding supporting frame, a writing brush fixing assembly, a pushing assembly and the like, wherein, the sliding supporting frame is fixedly connected to the upper portion of the first supporting frame, the writing brush fixing assembly is arranged on the sliding supporting frame, and the pushing assembly is arranged above the first supporting frame. Through a glue solution scraping and brushing assembly, a first scraping plate moves upwards to scrape the glue solution on a writing brush, a stretched fifth spring returns to drive the first scraping plate to move towards the direction close to a second sliding supporting frame, so that the first scraping plate fully scrapes the glue solution along a writing brush tip, a brushing plate moves upwards to comb the writing brush tip smoothly, a second scraping plate fully smooths the writing brush tip, and a slotting sliding rail plate limits the second scraping plate, so that the writing brush tip is prevented from being bent.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

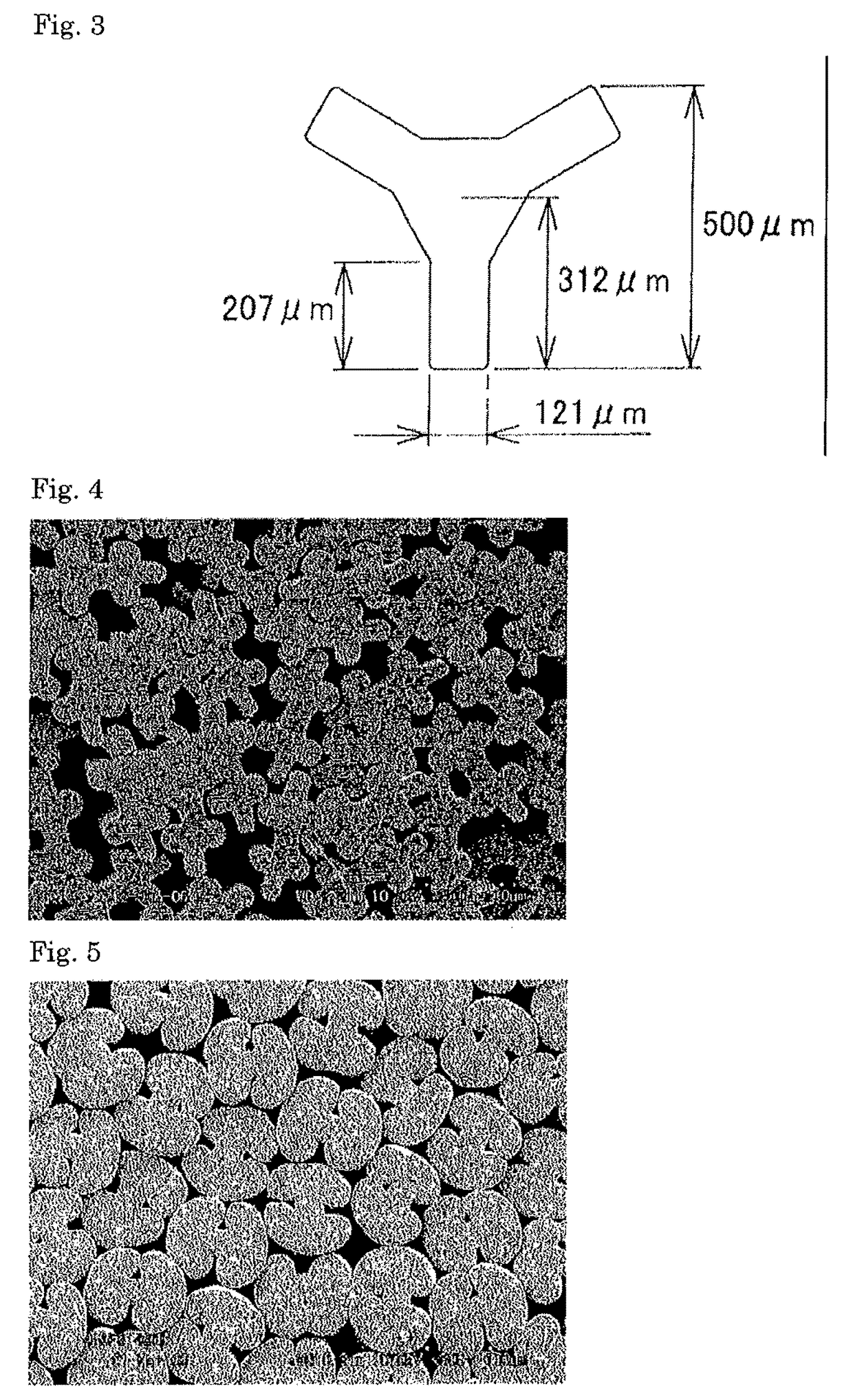

Anti-static polytetrafluoroethylene fiber and preparation method thereof

InactiveCN109972226AReduced volume specific resistanceReduce surface resistanceElectroconductive/antistatic filament manufactureMonocomponent halogenated hydrocarbon artificial filamentTetrafluoroethyleneCarding

The invention discloses an anti-static polytetrafluoroethylene fiber. The fiber is prepared from, by weight, 100 parts of polytetrafluoroethylene dispersion resin and 10-30 parts of nano aluminium powder; the anti-static polytetrafluoroethylene fiber is subjected to surface anti-static finishing. According to a preparation method, in the manufacturing process, and metal aluminium powder is mixed,so that the volume specific resistance of the polytetrafluoroethylene fiber is greatly lowered from 1,018 omega*cm to 1,010 omega*cm; meanwhile, a wool top after carding is subjected to dipping finishing through an anti-static solution, the surface resistance of the fiber is further lowered, so that in the carding and net laying process of the fiber, charges generated between the fiber and a carding machine and charges generated through fiber friction can be effectively dissipated in time, the carding difficulties such as static electricity gathering, roller twined by fibers and flyings can beavoided, carding is improved, the net formation performance is improved, and net laying is even; the thickness, uneven gram weight and the like of a needled felt are effectively reduced, and the appearance and application performance of the needled felt are improved.

Owner:SHANGHAI LINFLON FILM TECH +1

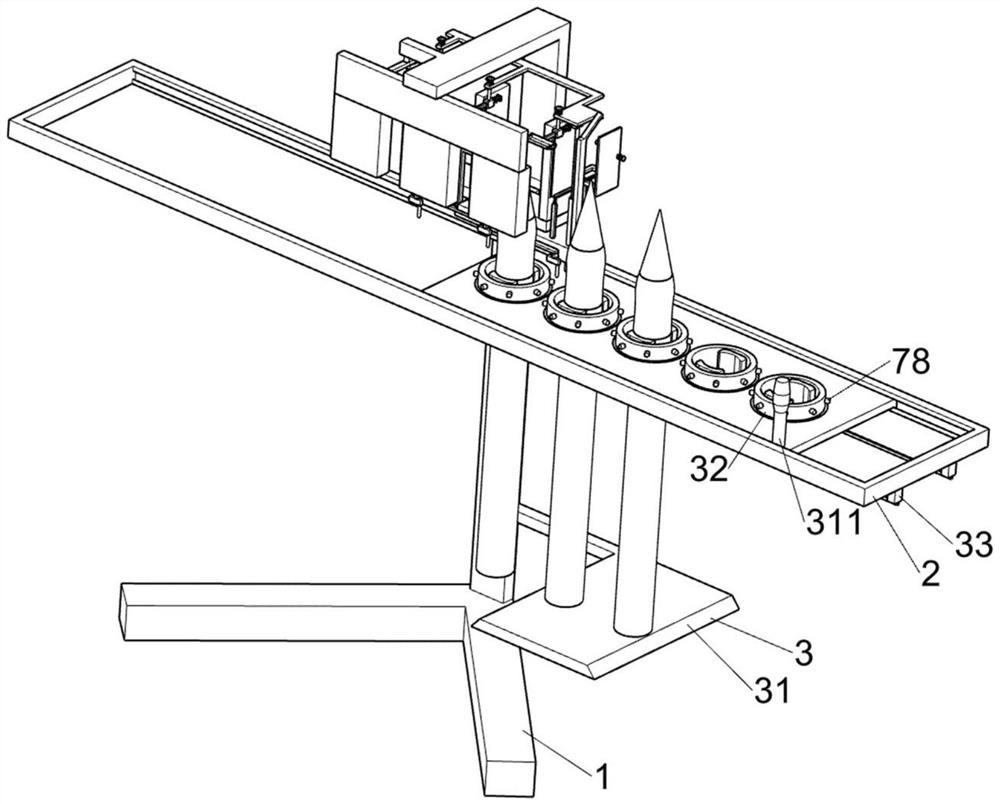

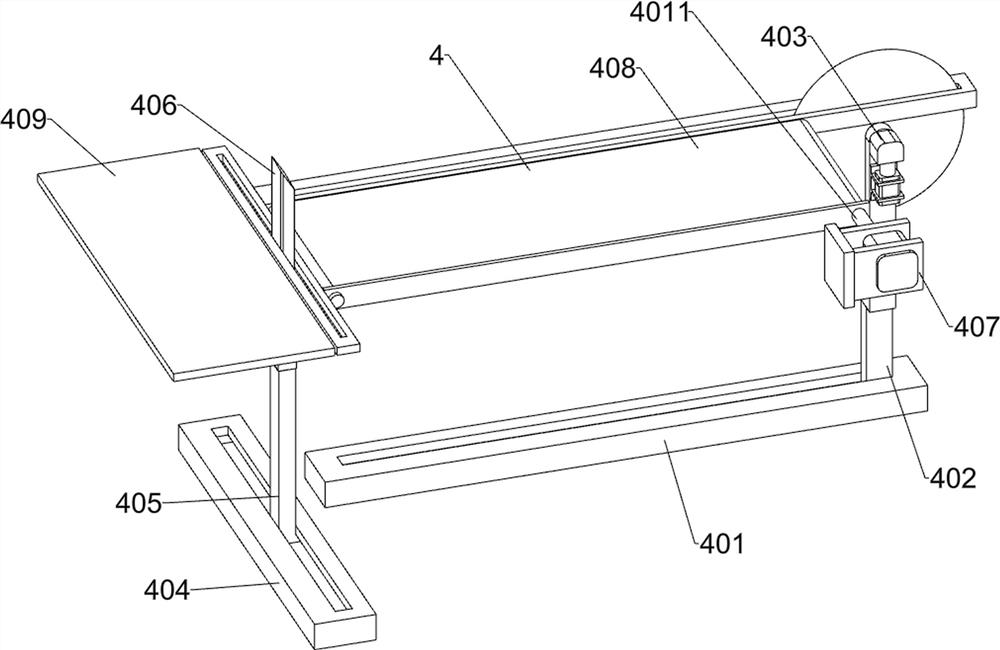

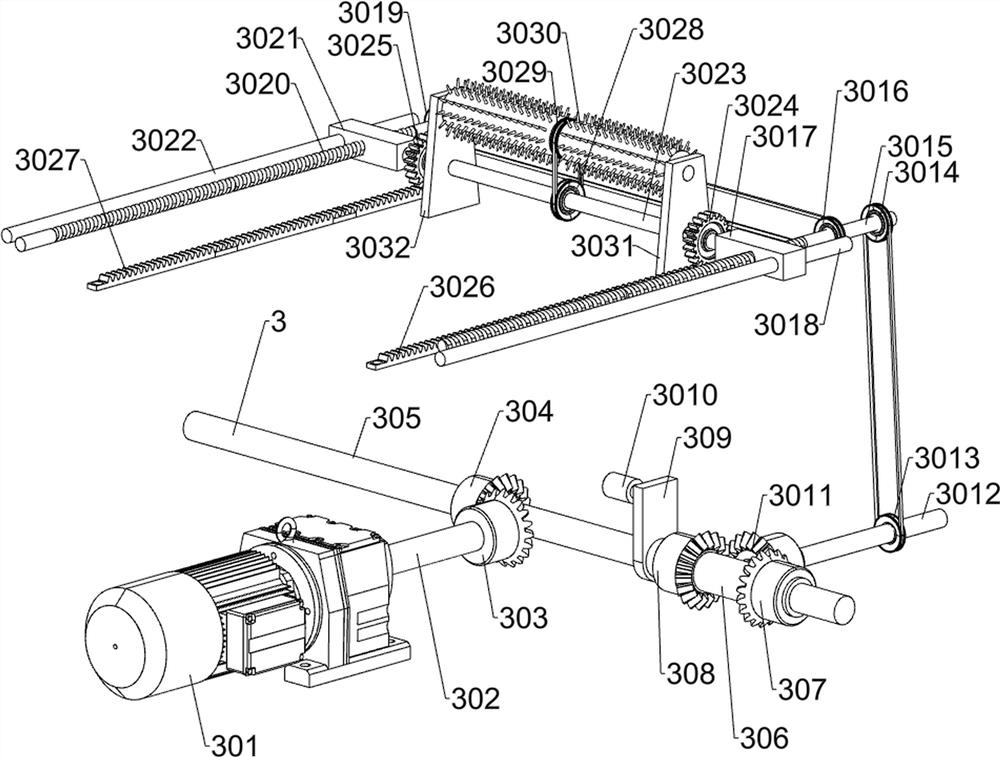

Hydroponic sponge separation device capable of carding root systems

InactiveCN112586330ARealize cardingAvoid damageAgriculture gas emission reductionCultivating equipmentsAgricultural engineeringMaterial transfer

The invention relates to the field of sponge, in particular to a hydroponic sponge separation device capable of carding root systems. The invention aims to provide the hydroponic sponge separation device capable of carding the root systems. According to the technical scheme, the hydroponic sponge separation device capable of carding the root systems comprises a bottom frame, a material transferring unit, an arranging unit, a dividing unit and a control screen; the bottom frame is connected with the material transferring unit; the bottom frame is connected with the arranging unit; the bottom frame is connected with the dividing unit; the bottom frame is connected with the control screen; and the material transferring unit is connected with the arranging unit. The device realizes carding ofthe sponge seedling root systems, can prevent the root systems from being damaged during cutting, replaces manual treatment and greatly improves the efficiency.

Owner:杨云飞

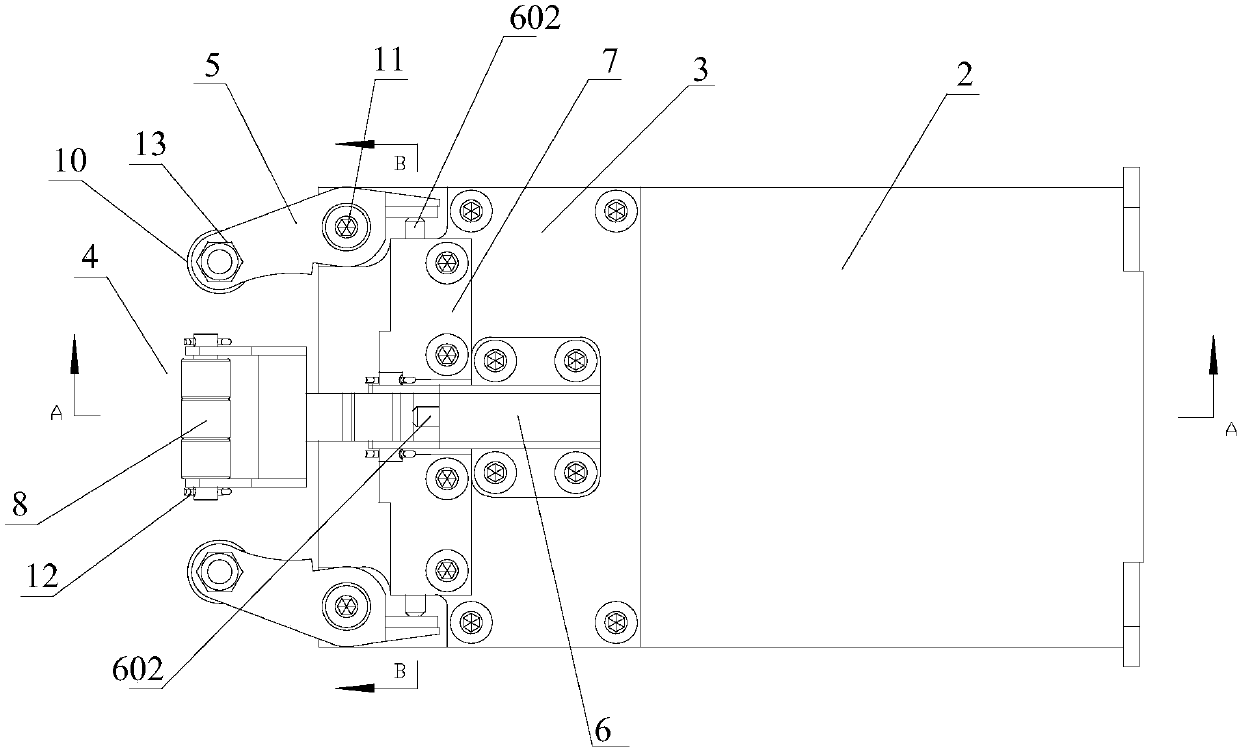

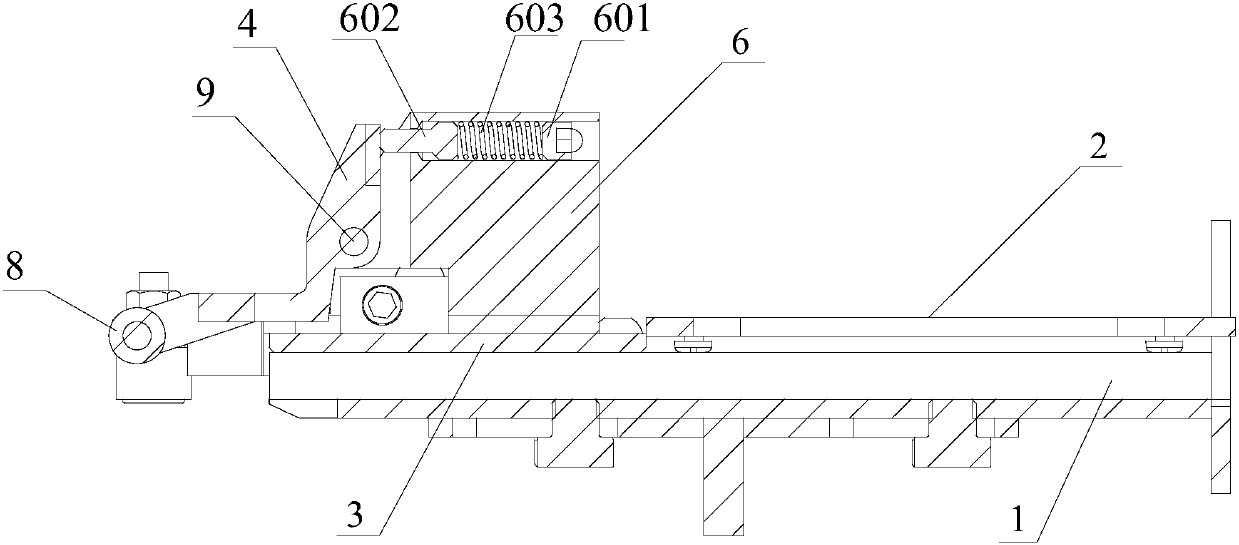

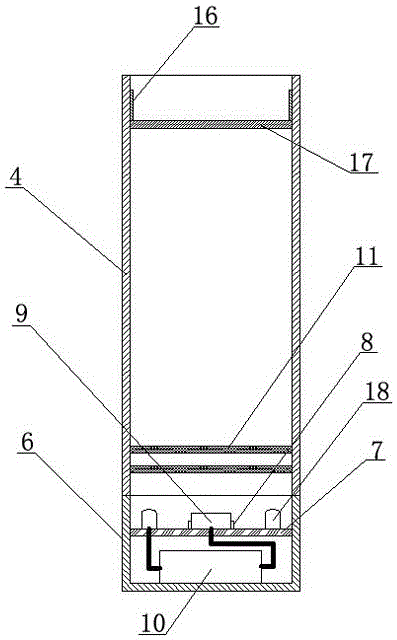

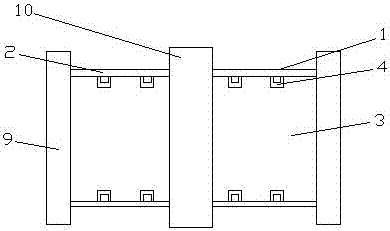

Continuous cap feeding device

ActiveCN106144991AReduce frictionImprove efficiencyConveyorsFlanged caps applicationEngineeringBottle cap

The invention provides a continuous cap feeding device which comprises a cap sliding trough, a cover plate, a fixing plate, a front swing arm and lateral swing arms, wherein the cover plate and the fixing plate are arranged on the cap sliding trough. The front swing arm is located in the middle of the output direction of the cap sliding trough, and the lateral swing arms are mounted on the two sides of the output direction of the cap sliding trough correspondingly and distributed symmetrically. A first spring seat is arranged in the middle of the fixing plate, and second spring seats are arranged on the two sides of the fixing plate correspondingly. A first spring reset mechanism is arranged in the first spring seat, and second spring reset mechanisms are arranged in the second spring seats. A plurality of first wheels rotating in the horizontal direction are arranged at the front end of the front swing arm, and the rear end of the front swing arm is connected with the first spring reset mechanism. Second wheels rotating in the vertical direction are arranged at the front ends of the lateral swing arms, and the rear ends of the lateral swing arms are connected with the second spring reset mechanisms. According to the continuous cap feeding device provided by the invention, bottle caps are not damaged and are smoothly settled, the bottle cap percent of pass is increased, and production efficiency is improved.

Owner:海口尚维科技有限公司

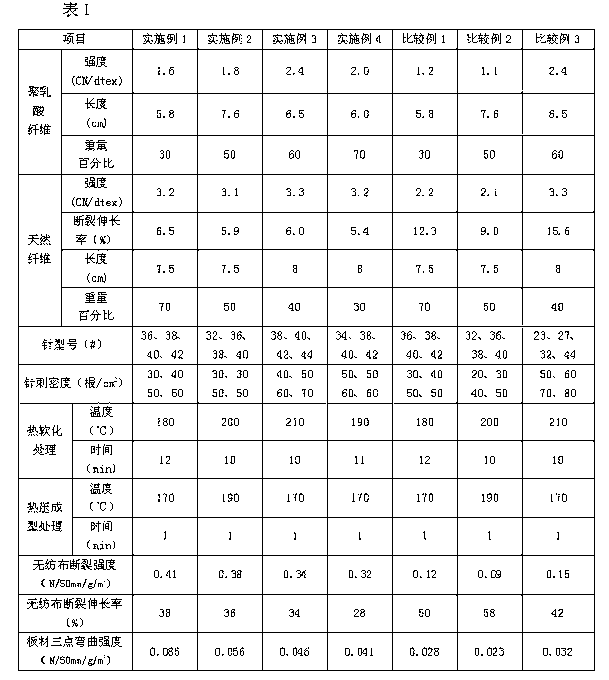

Automotive plate and production method thereof

InactiveCN103255580AHigh strengthGood dimensional stabilityHeating/cooling textile fabricsNon-woven fabricsFlexural strengthNonwoven fabric

The invention discloses an automotive plate and a production method thereof. The plate is made of non-woven fabrics formed by mixing polylactic acid fibers with natural fibers, the strength of the polylactic acid fibers is higher than 1.4CN / dtex, the strength of the natural fibers is higher than 3.0CN / dtex, and the three-point bending strength of the plate is higher than 0.04N / 50mm / g / m<2>. The automotive plate has the advantages of high strength, fine dimensional stability, no environmental pollution and simple processing technology.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Screw conveyer for pullout seedling roots of shallow-mud field water chestnuts

The invention provides a screw conveyer for pullout seedling roots of shallow-mud field water chestnuts. The screw conveyer comprises a rotary drum, pulling teeth and a hair brush rotary drum, whereinradial pulling teeth are arranged on the external surface of the rotary drum; multiple seedling root conveyors are arranged in front of the rotary drum; a supporting frame is arranged behind and above the rotary drum, and the hair brush rotary drum is arranged on the supporting frame; oblique-line-segment tail parts of the seedling root conveyors extend above the middle part of the hair brush rotary drum, radial gaps are reserved among hair brushes on the hair brush rotary drum; a scraper rod is arranged behind the hair brush rotary drum, and scraper plates are arranged on the scraper rod andare over against the gaps reserved among the hair brushes and extend into the gaps; the supporting frame is fixed onto connecting plates at the left and right sides; lower ends of the connecting plates are rotatably connected with a rolling shaft through bearings; an arc-shaped stock guider is arranged behind the supporting frame; and a seedling root cleaning rotary drum is arranged on the arc-shaped stock guider. According to the screw conveyer, water chestnut seedlings can be excellently cleaned and conveyed, the blockage of the seedlings cannot be caused, and the combing is more smooth.

Owner:芜湖乐佳自动化机械有限公司

A mobile oiling device for high-grade crocodile skin smooth texture

ActiveCN110331235BEasy to processOil evenlySkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentElectric machineFishery

The invention discloses high-grade crocodile leather oiling equipment moving with texture. The equipment comprises a machine body, wherein a moving cavity opening downward is formed in the machine body; a processing device which is used for conditioning the crocodile leather texture and oiling crocodile leather is arranged in the moving cavity; and a plug is rotated firstly, maintenance oil is added into an oil tank, and then a power motor is started, so that a power shaft, a long sliding key and a third bevel gear are driven to rotate. Compared with processing equipment of other leather materials, the high-grade crocodile leather oiling equipment is more suitable for combing the texture of the crocodile leather and oiling the crocodile leather; and combing the crocodile leather texture and oiling the crocodile leather are achieved through a heatable roller, so that each piece of the leather is uniformly oiled and combed, and it is convenient for people to process the crocodile leatherinto leather bags, leather shoes and the like.

Owner:江苏世丰企业管理咨询有限公司

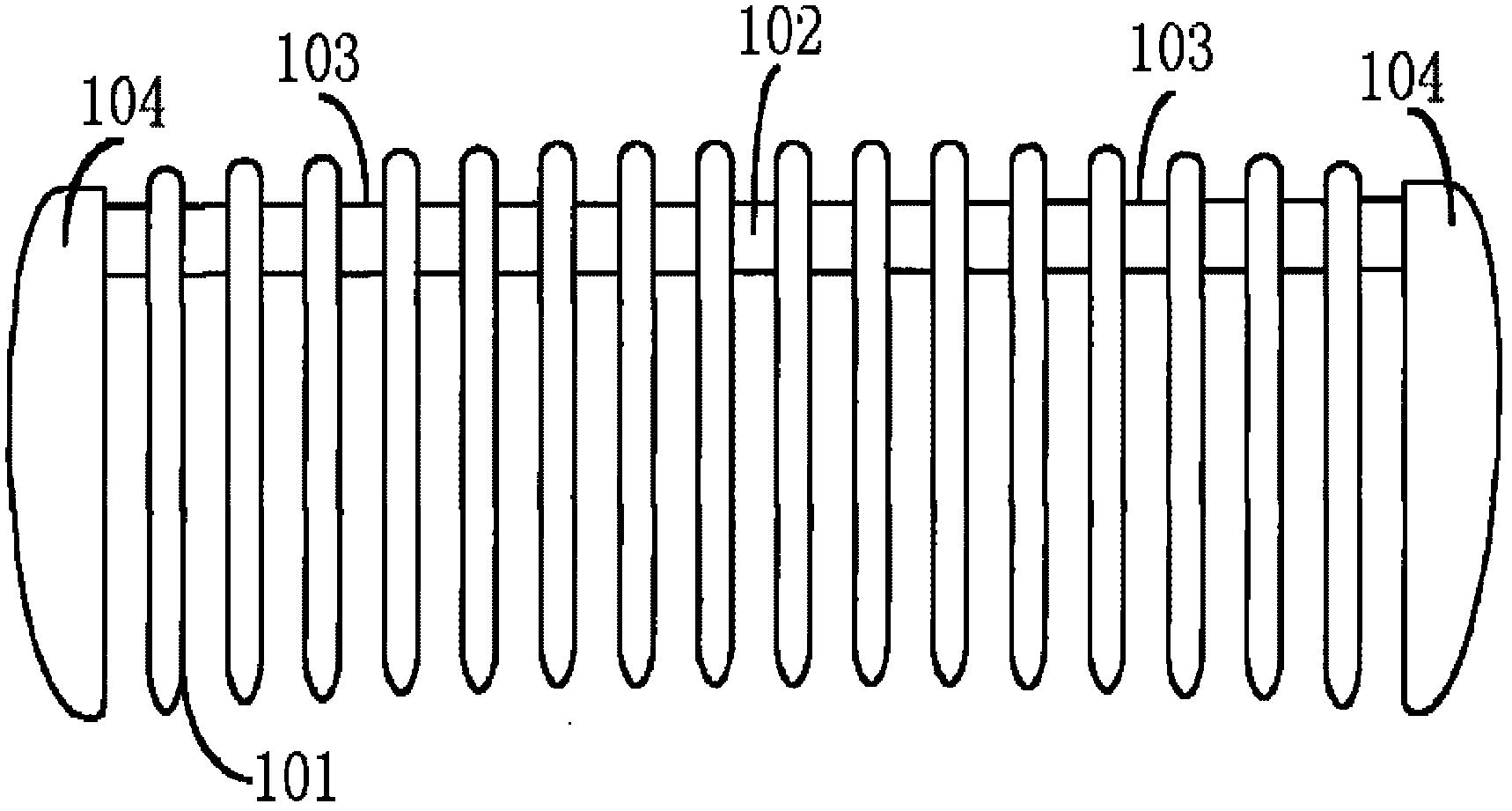

Fiber for artificial hair with improved processability and hair accessory using the same

An artificial hair which is composed of synthetic fibers such as acrylic fibers or vinyl chloride fibers and which is characterized in that the cross section of each fiber has a shape consisting of one major axis and at least two minor axes nearly perpendicular to the major axis and that the single-fiber fineness is 25 to 70 dtex. This artificial hair is soft to the touch and bulky (voluminous) to impart a good feel to hair accessories and exhibits excellent combing properties and braidability, thus giving hair accessories (such as wigs, hairpieces, braids, extension hair and doll hair) which have excellent feel and settability.

Owner:KANEKA CORP

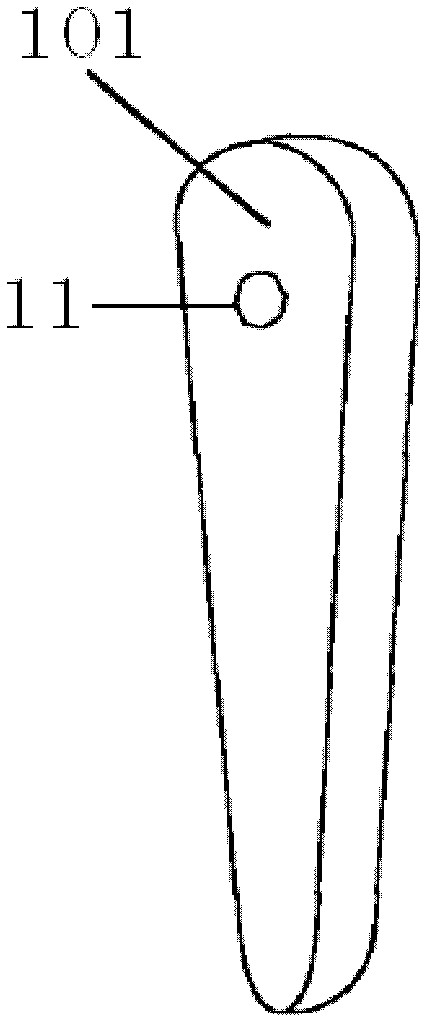

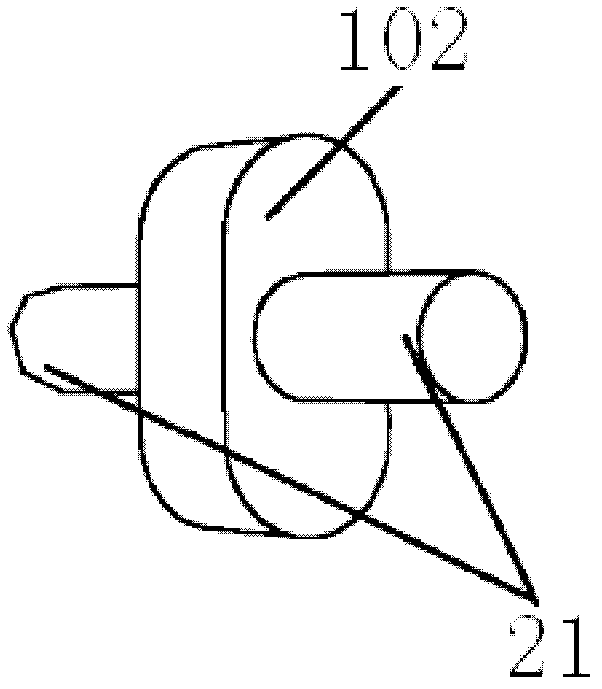

Comb

The invention discloses a comb, which comprises a connecting shaft, comb teeth, auxiliary teeth, spacers, fasteners and a positioning shaft. The comb teeth, the auxiliary teeth and the spacers are respectively provided with first connecting holes, second connecting holes and third connecting holes; the comb teeth and the auxiliary teeth are arranged in the middle and two ends of the connecting shaft via the first connecting holes; the spacers are disposed on the connecting shaft via the third connecting holes, and each spacer is located between two corresponding adjacent comb teeth or between the corresponding comb tooth and the corresponding auxiliary tooth which are adjacent; the fasteners are disposed at two ends of the connecting shaft; the comb teeth, the spacers and the auxiliary teeth are respectively provided with first limiting holes, second limiting holes and limiting grooves, and the positioning shaft is respectively connected with the comb teeth, the spacers and the auxiliary teeth via the first limiting holes, the second limiting holes and the limiting grooves. Components of the comb are connected reliably, the problem that the components of the comb are separated during usage of the comb can be avoided, and the comb can deform according to change of combing resistance, and realizes smooth combing.

Owner:重庆谭木匠工艺品有限公司

Comb provided with teeth with holes

The invention relates to a comb, in particular to a comb provided with teeth with holes, and belongs to the field of articles for daily use. The comb mainly comprises a comb handle, a comb back and comb teeth, wherein the comb handle is in a hollow cylinder shape, a handle cover is arranged at the tail end of the comb handle, and a canned hair care solution with pressure is contained in the comb handle; a round hole for facilitating hanging is formed in one end, which is far away from the comb handle, of the comb back; the comb teeth consist of long teeth and short teeth which are arranged alternately; holes are formed in tooth tops of the short teeth, the short teeth are hollow, and a pipeline is arranged in the comb back and communicated with all the holes of the short teeth; the pipeline extends to the comb handle end to be connected with the canned hair care solution, and the hair care solution is controlled by a button type valve capable of resetting automatically to flow out or not. The tail end of the handle cover is flat, so that the comb can be vertically placed conveniently. The comb teeth are made of plastic or ceramic. A button is pressed by fingers to enable the hair care solution to flow out of the holes of the short teeth, hair caring while hair combing is facilitated, and the hair care solution is evenly used. The comb is very convenient to use, hang and place.

Owner:王志成

Device capable of packing and compacting rural straws

InactiveCN110202817ASolve the problem of not being able to effectively pack and compact in high densityImproved compaction of high-density balesPressesHigh densityVolumetric Mass Density

The invention provides a device capable of packing and compacting rural straws. The device comprises a teasing roller, a roller pressing chamber, double pressing rollers, a conveying chamber, a forming chamber, a spring rod, a teasing motor, a roller pressing motor, a spiral conveyor motor and a spiral conveyor shaft, wherein the teasing roller is arranged inside a feeding groove, the teasing motor is arranged on the rear side of the teasing roller, the roller pressing chamber is formed in the lower side of the feeding groove, the double pressing rollers are arranged inside the roller pressingchamber, the roller pressing motor is installed on the rear sides of the double pressing rollers, the conveying chamber is formed in the lower side of the roller pressing chamber, the spiral conveyorshaft is arranged inside the conveying chamber, the spiral conveyor motor is installed on the left side of the spiral conveyor shaft, the forming chamber is formed in the right side of the conveyingchamber, and the spring rod is arranged on the right side of a discharging door. According to the design, the problem that an original straw packaging and compacting machine cannot effectively realizehigh-density packaging and compaction is solved, the structure of the device is reasonable, and the straws can be conveniently packed and compacted in a high-density manner.

Owner:王星

Production method of silk pupa mask paper

The invention discloses a production method of silk pupa mask paper, comprising fiber, cotton opening, cotton blending, carding, web paving, spunlace, draining, drying, coiling and cutting. Before the carding step, a static electricity removing device is added, a humidifier is adopted to cause the humidity of a whole space to be kept within 65-70%, the revolving speed of a carding machine cylinder is reduced in the carding process to cause the revolving speed to be maintained within 600-700rpm, the cylinder rotates to generate airflow in the carding process, a screen is adopted to disperse the airflow, four sets of disordered rollers are arranged to strip mulberry silk in the cotton stripping process, wherein the revolving speed of the disordered rollers is maintained within 300-350rpm, a 27-roll drawing roller is adopted, high-density cotton-type card clothing is used, the angle of the card clothing is not greater than 45 degrees, by arranging an L-shaped arc screen at the bottom of the cylinder, mulberry silk can uniformly form a web, and the whole space is uniformly humidified by utilizing the static electricity removing device and adopting the humidifier, thereby removing static electricity generated in the carding process of the mulberry silk.

Owner:郑伟明

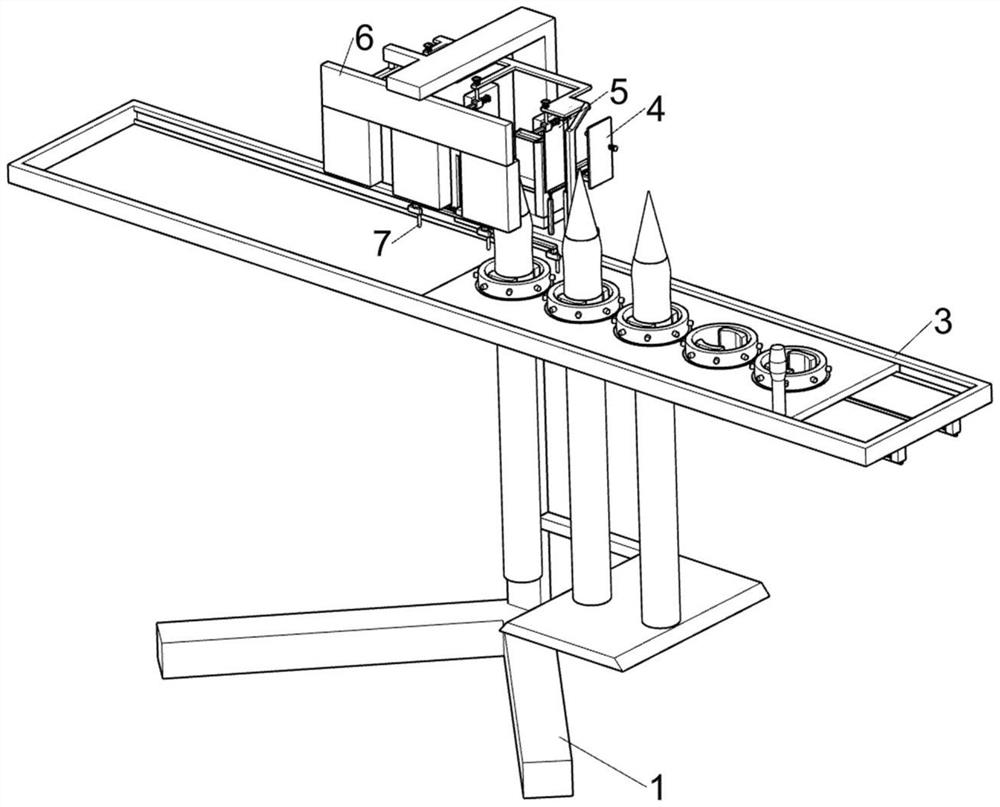

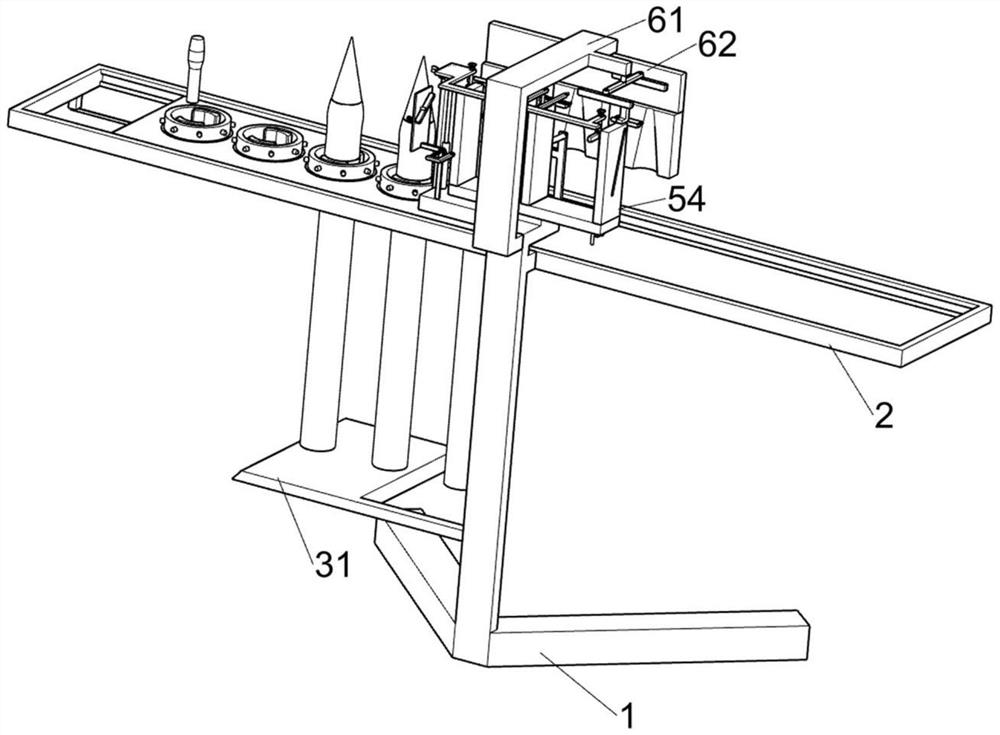

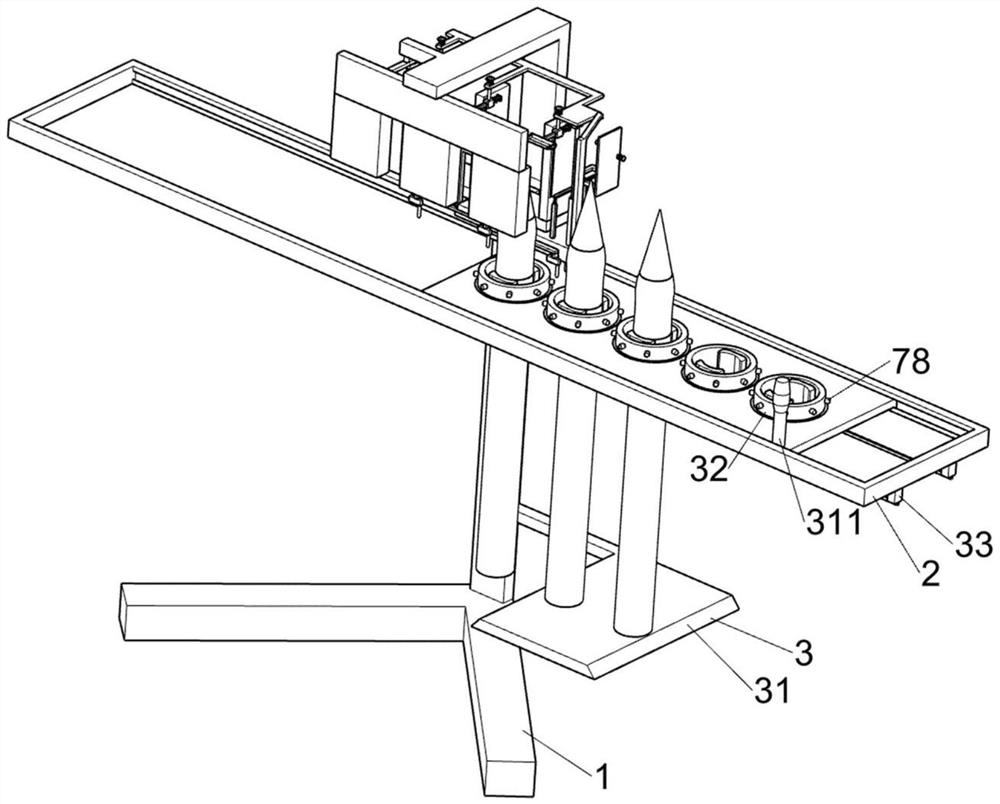

A brush combing robot

ActiveCN105946395BPlay the role of squeezing the tip of the penImprove carding efficiencyPen repairingNibsEngineeringRobot

Owner:ANHUI ZHONG XIN MOLD IND DEV CO LTD

Ceramic comb

The invention relates to a ceramic comb and belongs to the technical field of ceramic production. The comb comprises a comb body and comb teeth, which are integrated, wherein the comb body and the comb teeth are both made of ceramics and integrally formed with a high-temperature firing method. The ceramic comb has the advantages of high strength, smoothness for combing and high possibility of cleaning; meanwhile, a one-step forming method is adopted, so that the manufacturing process is simplified, the difficulty is lowered, the rejection rate is reduced, and the cost is saved.

Owner:陈锐群

A reciprocating glue cleaning device for brush gluing

The invention relates to the field of brush processing, in particular to a reciprocating glue cleaning device for brush gluing, which includes a first support frame, a sliding support frame, a brush fixing component, a pushing component, etc.; a sliding support is fixed above the first support frame frame, the writing brush fixing component is arranged on the sliding support frame, and the pushing component is arranged above the first support frame. Through the glue scraper assembly, the first scraper moves upward to scrape off the glue on the brush, and the stretched fifth spring returns to drive the first scraper to move toward the second sliding support frame, so that the first scraper The plate scrapes off the glue fully along the tip of the brush, the brush plate moves upward to comb the tip of the brush smoothly, the second scraper fully smooths the tip of the brush, and the slotted slide rail plate limits the second scraper to prevent the brush from The pen is curved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

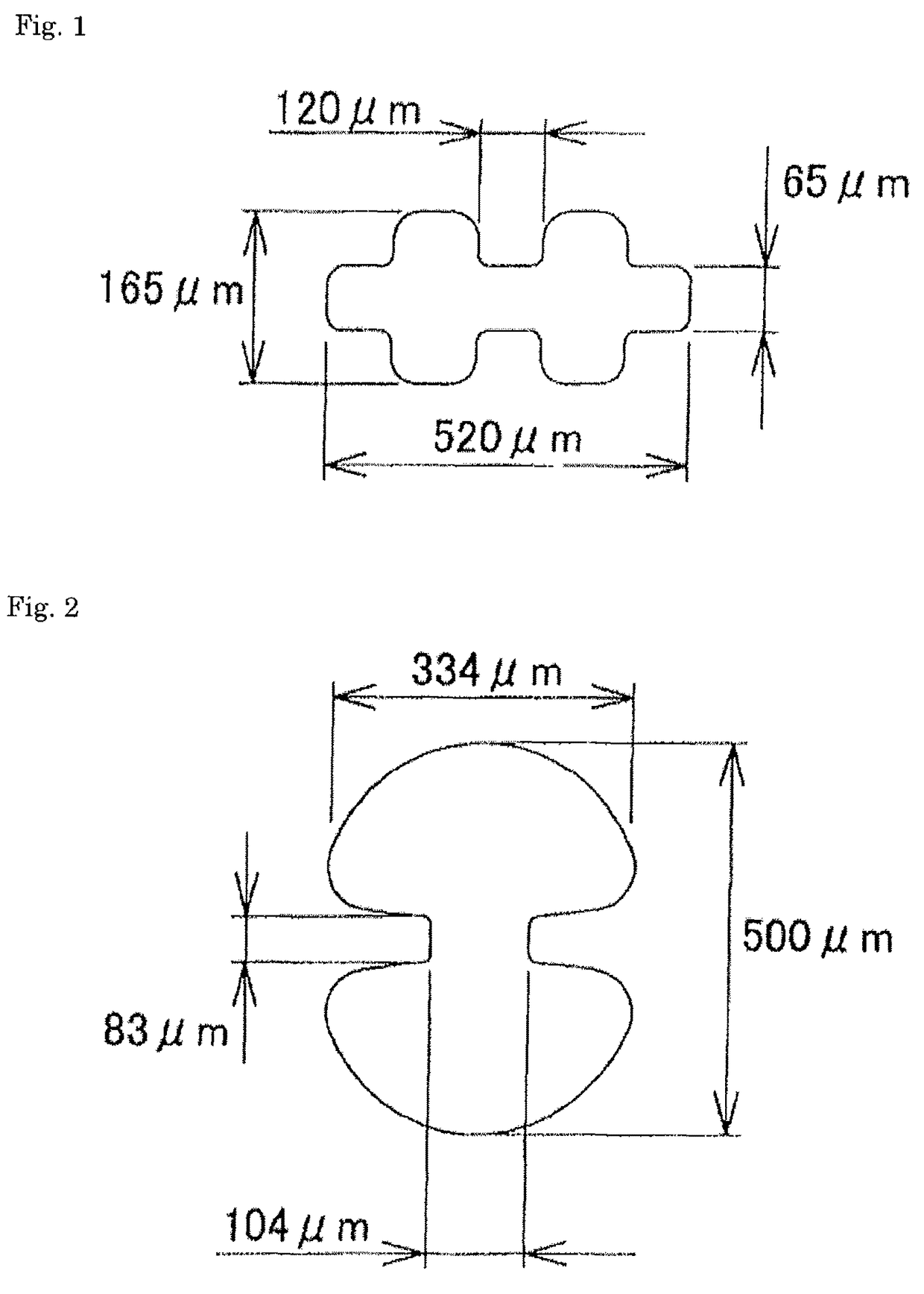

Apparatus on a carding machine for processing textile fibres, for example cotton, synthetic fibres and the like, with a cylinder

An apparatus on a carding machine for processing textile fibres, with a cylinder, has, in the preliminary carding zone, after carding zone and / or underneath carding zone, covering elements which lie opposite the cylinder clothing. A fixed carding element is associated with at least one cover element. The spacing of the cylinder clothing from the clothing of the fixed carding element is smaller than the spacing from the cover element. In order to reduce nep formation, to allow improved carding work and to give a better carding result, between at least one clothing strip of the fixed carding element and a cover element arranged upstream and / or downstream thereof, there is arranged an air guide element the spacing of which with respect to the cylinder clothing gradually decreases or increases.

Owner:TRUTZSCHLER GMBH & CO KG

A continuous cap feeding device

ActiveCN106144991BAvoid the problem of stuck positionReduce frictionConveyorsFlanged caps applicationEngineeringBottle cap

The invention provides a continuous cap feeding device which comprises a cap sliding trough, a cover plate, a fixing plate, a front swing arm and lateral swing arms, wherein the cover plate and the fixing plate are arranged on the cap sliding trough. The front swing arm is located in the middle of the output direction of the cap sliding trough, and the lateral swing arms are mounted on the two sides of the output direction of the cap sliding trough correspondingly and distributed symmetrically. A first spring seat is arranged in the middle of the fixing plate, and second spring seats are arranged on the two sides of the fixing plate correspondingly. A first spring reset mechanism is arranged in the first spring seat, and second spring reset mechanisms are arranged in the second spring seats. A plurality of first wheels rotating in the horizontal direction are arranged at the front end of the front swing arm, and the rear end of the front swing arm is connected with the first spring reset mechanism. Second wheels rotating in the vertical direction are arranged at the front ends of the lateral swing arms, and the rear ends of the lateral swing arms are connected with the second spring reset mechanisms. According to the continuous cap feeding device provided by the invention, bottle caps are not damaged and are smoothly settled, the bottle cap percent of pass is increased, and production efficiency is improved.

Owner:海口尚维科技有限公司

Automatic animal fur carding equipment

The invention relates to animal fur treatment equipment, in particular to automatic animal fur carding equipment. The technical problem to be solved by the invention is to provide the automatic animalfur carding equipment which can improve the fur carding efficiency, is uniform in the carding process and is high in automation degree. The automatic animal fur carding equipment comprises a wall-mounted frame, expansion screws, an electric push rod, a chain wheel, a first fixed block, a chain and the like; a plurality of sets of expansion screws are arranged on the wall-mounted frame, the electric push rod is connected to the other side of the wall-mounted frame, the chain wheel is rotationally connected to a telescopic rod of the electric push rod, the first fixed block is connected to theside, close to the wall-mounted frame, of the electric push rod, and the chain is connected to the chain wheel. According to the automatic animal fur carding equipment, fur is fixed to a clamping device to be flattened, and the fur is carded through rotation of a bristle wheel, so that manpower can be liberated in the carding process, and the flattened fur can be evenly carded.

Owner:袁鸿宽

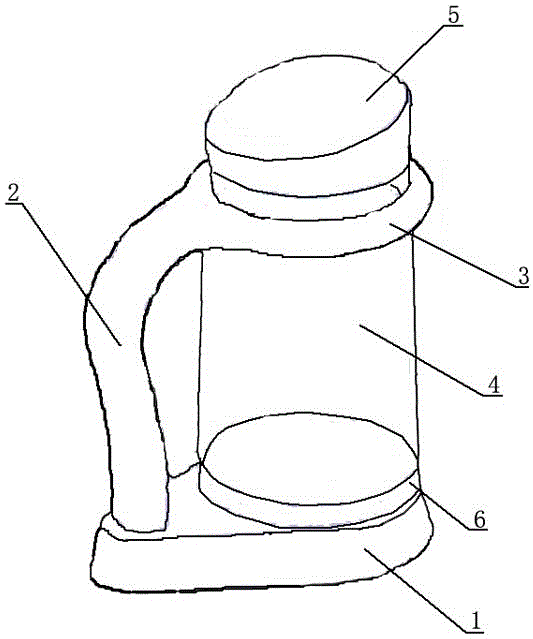

Domestic device for preparing hydrogen-enriched nutritive water

InactiveCN106145280AProtection from electrolysis of harmful substancesEquilibrium hydrogen ion distributionWater/sewage treatment by substance additionWater/sewage treatment apparatusWater storageHydrogen

The invention relates to a domestic device for preparing hydrogen-enriched nutritive water. The domestic device comprises a water storage cylinder body and a pedestal, wherein the water storage cylinder body comprises a cylindrical cup body, a cup cover and a base; an electrode clamping plate is arranged in the base; a lithium battery component is arranged in a lower cavity of the base; two air hole plates are arranged in an upper cavity of the base from top to bottom; a strip-shaped through hole is formed in each air hole plate; a detachable filter element component is also arranged at the upper part of the cup body and comprises an outer ring, an inner ring and a filter element; the outer ring is arranged outside the inner ring in a sleeving manner; in addition, the outer ring and the inner ring are fixed together through three connecting rods which are uniformly distributed; the filter element is arranged in a cavity between the outer ring and the inner ring. According to the domestic device for preparing the hydrogen-enriched nutritive water, disclosed by the invention, the hydrogen-enriched nutritive water can be generated; the filter element is arranged at the front end of the cup body, so that electrolyzed hydrogen-enriched water is healthier.

Owner:许昌百昌纳米科技有限公司

A feeding mechanism for brush carding robot

ActiveCN106166909BPlay the role of squeezing the tip of the penImprove carding efficiencyPen repairingNibsEngineeringMechanical engineering

The invention discloses a pen point combing robot feeding mechanism which comprises a fixed disc, a rotary disc, at least three sets of combing belts and a conveying mechanism. The rotary disc is arranged in the middle of the fixed disc and can be rotated. Each set of combing belt comprises a spring and a rope, wherein one end of the spring is connected with one end of the rope, the other two ends are connected to the fixed disc and the rotary disc respectively, the three sets of combing belts are distributed at different positions on the periphery of the fixed disc, the conveying mechanism comprises a stand column, a sliding base capable of sliding up and down on the stand column and a clamping jaw arranged on the sliding base and capable of clamping a pen. The pen point combing robot feeding mechanism automatically combs a pen point, and is high in combing efficiency and uniform in combing.

Owner:ANHUI ZHONG XIN MOLD IND DEV CO LTD

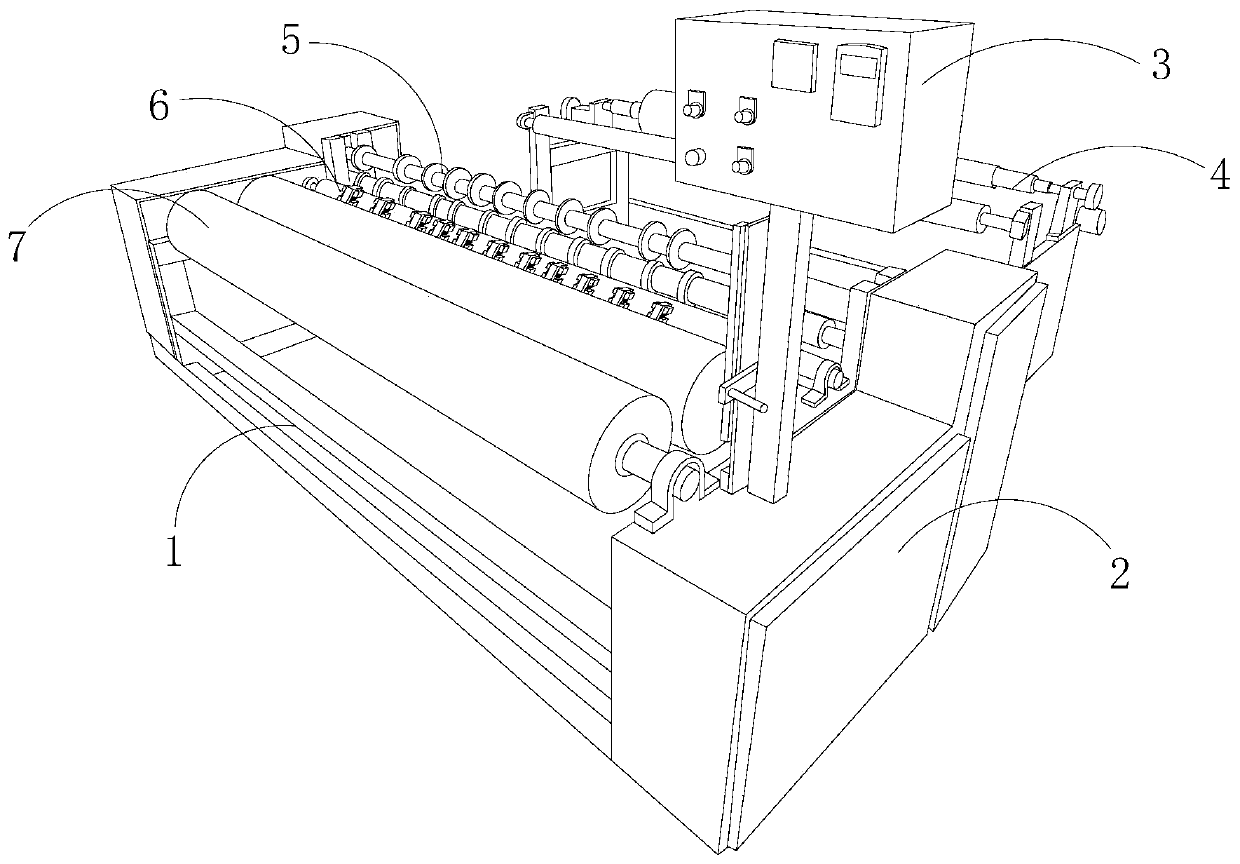

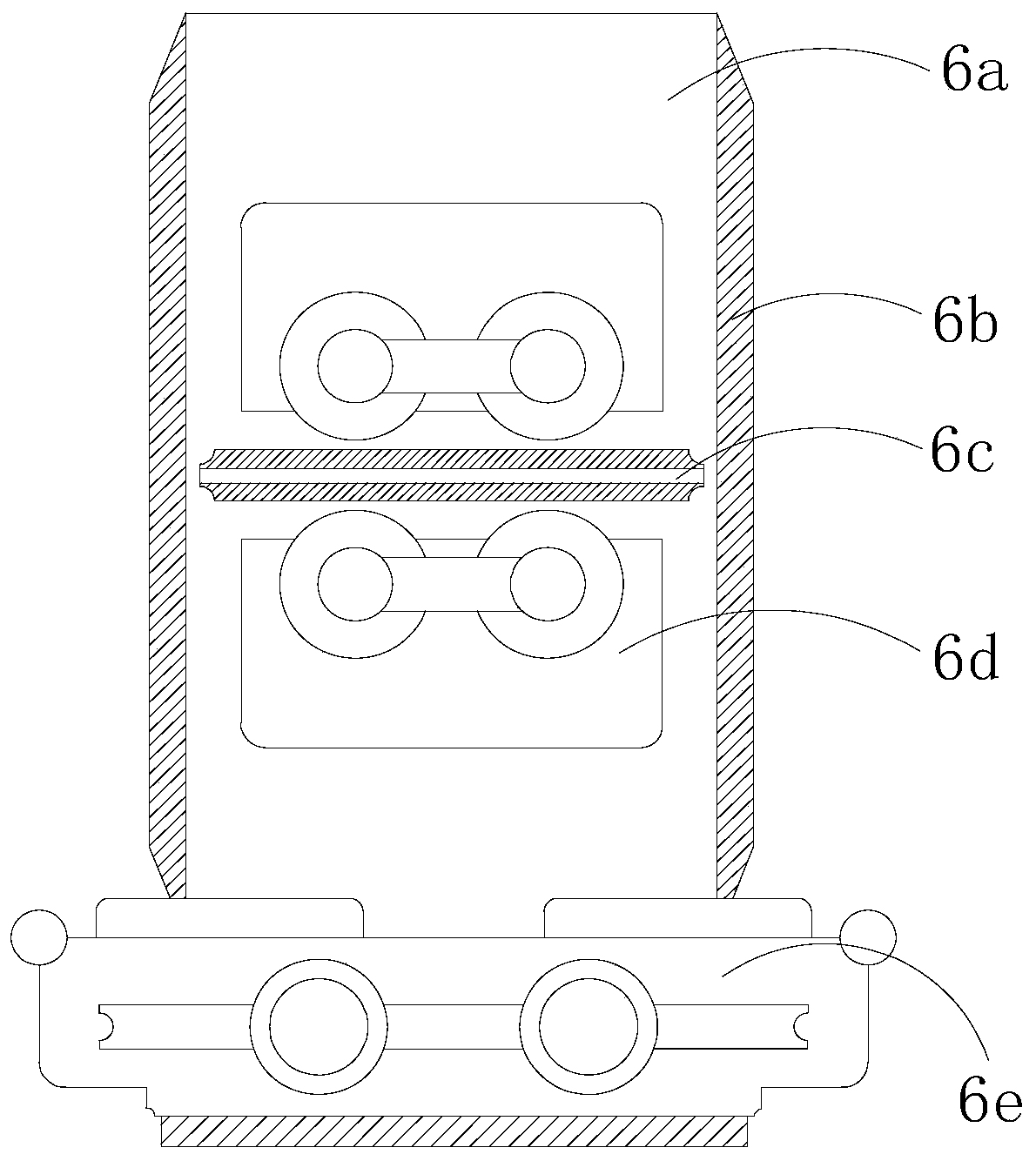

Smooth-combing and entangling and tearing preventing non-woven fabric fast slitting device

The invention discloses a smooth-combing and entangling and tearing preventing non-woven fabric fast slitting device. The smooth-combing and entangling and tearing preventing non-woven fabric fast slitting device structurally comprises an equipment body, a checking box, a controller, a conveying roller shaft, a slitting roller, an entangling preventing device and a rolling roller. The smooth-combing and entangling and tearing preventing non-woven fabric fast slitting device has the beneficial effects that due to cooperation of a clamping plate, a fixed cutting plate and a continuous cutting piece, when non-woven fabric passes through the slitting roller to be slit, initiative tightening and separating of slitting line positions are conducted on the non-woven fabric, and the phenomenon thatthe moment the non-woven fabric is cut, due to dispersion of tightening force on the two edges, the slit non-woven fabric is overlapped due to the force effect, and the that the sizes are not uniformduring subsequent slitting is avoided; the entangling preventing device is used for conducting uniform line smooth combing on velvets generated due to the contact friction between the surface of thenon-woven fabric and the machine under the effect of a scraping and sweeping body; and due to mutual contact between the non-woven fabric and a flat removing assembly, the velvets can be movably flatly cut off, and therefore the phenomenon that during rolling, the two edges of the non-woven fabric are entangled together due to the velvets, and when the non-woven fabric is separated to be used, dueto entangling of the velvets, the overall non-woven fabric is torn up is prevented.

Owner:林瑞婷

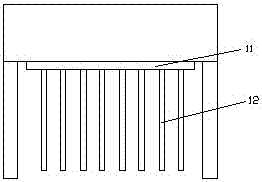

Knitting wool carding machine for woollen blanket

The invention discloses a fleece carding machine for wool blankets, which comprises a wool carding machine body, a conveying platform is arranged on the upper end of the wool carding machine body, a conveyor belt device is arranged on the conveyor belt device, and small pneumatic hydraulic presses are installed on both sides of the conveyor belt device. Disk device, the upper end of the small pneumatic pressure plate device is provided with a cantilever head, the bottom end of the cantilever head is equipped with a cylinder part, the lower end of the cylinder part leads out to the cylinder rod, and the lower end of the cylinder rod is provided with a blanket pressure plate body, the The two ends of the conveying table are equipped with static electricity removers, the center of the conveying table is equipped with a wool carding machine for woolen wool, and the lower end of the carding machine for woolen blankets is equipped with multiple rows of teeth for carding woolen wool. Through the above method, the present invention can be specially used for wool wool carding work, and the wool blanket is firmly attached to the conveyor belt device through a small pneumatic pressure plate device, so that the wool blanket will not move when it passes through the multiple rows of yarn carding teeth of the wool wool carding machine , so that the wool on the blanket can be combed smoothly.

Owner:WUXI TAISHUN FLOCKING MACHINERY FACTORY

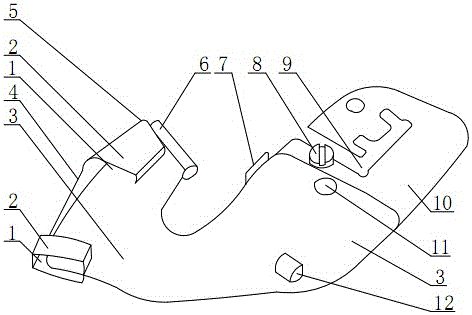

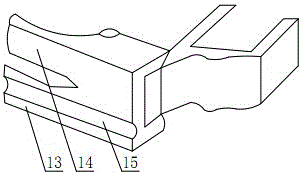

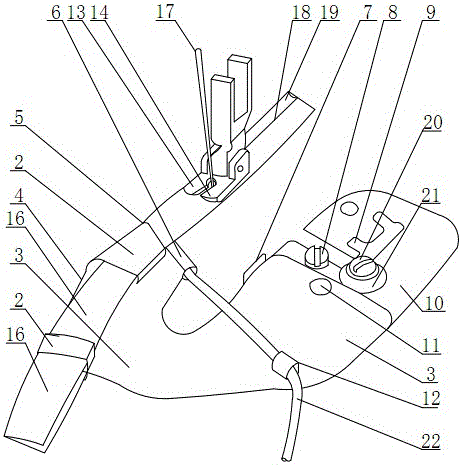

Sailor's cap on the hat mouth bayonet mouthpiece

ActiveCN104342855BSimple structureEasy to manufactureWork-feeding meansPressersEngineeringPressure groove

The invention discloses a fastening strip mouth for a cap opening in a seaman's cap, and relates to the technical field of a cloth feeding or finishing mechanism for a sewing machine. The fastening strip mouth is prepared by the machine comprising a cloth finishing mechanism and a pressure foot, wherein the cloth finishing mechanism comprises a cloth finishing plate, a cloth finishing channel and a threading pipe; the cloth finishing channel with an inverted U-shaped cross section is arranged on the left side of the cloth finishing plate and comprises a cloth finishing channel housing with a rectangular cross section and a cloth finishing plate which is inserted in the cloth finishing channel housing from the left side; the cloth finishing channel housing and the cloth finishing plate are fixedly connected; the threading pipe is arranged on the cloth finishing plate; an outlet of the threading pipe is formed in the left part of the cloth threading channel outlet; the cloth finishing mechanism is fixed on the workbench surface of the sewing machine; the pressure foot comprises a left pressure foot plate and a right pressure foot plate; a rope pressing groove is formed in the lower part of the left pressure foot plate; the direction of the rope pressure groove is identical to the cloth outlet direction. The wrapped fastening strip mouth is uniform, can meet the quality requirement, and can be manufactured by one person, so that the efficiency of labor is increased by 50%, time is saved, and the yield is obviously increased and the quality is obviously improved.

Owner:JIHUA 3534 CLOTHING

Carding machine with function of uniform carding

The invention relates to the technical field of carding machines, and discloses a carding machine with a function of uniform carding. The carding machine comprises a bottom box, wherein the inner bottom wall of the bottom box is fixedly provided with two adjusting columns, the tops of the two adjusting columns are fixedly provided with clamped connection blocks respectively, the two clamped connection blocks are in clamped connection with threaded columns respectively, the sides, back onto each other, of the two threaded columns are in threaded connection with adjusting nuts respectively, a carding roller shaft is fixedly arranged between the opposite sides of the two threaded columns, and the left side and right side of the bottom box are fixedly provided with limiting boxes respectively.The carding machine with the function of uniform carding has the advantages that the limiting boxes are internally provided with anti-falling blocks, cotton winding rollers can be prevented from falling off from the limiting boxes through anti-falling plates, a power motor and a rotating shaft are provided with the anti-falling plates respectively, and the deviation of linkage belts can be avoided through the anti-falling plates, thereby effectively solving the problem that manufactured objects have many impurities due to the fact that carding of some existing carding machines is not very uniform.

Owner:YANCHENG ZHONGLI TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com