A reciprocating glue cleaning device for brush gluing

A cleaning device and reciprocating technology, applied in the repair of ink pens, printing, writing utensils, etc., can solve the problem of cleaning without glue, and achieve the effect of preventing offset and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

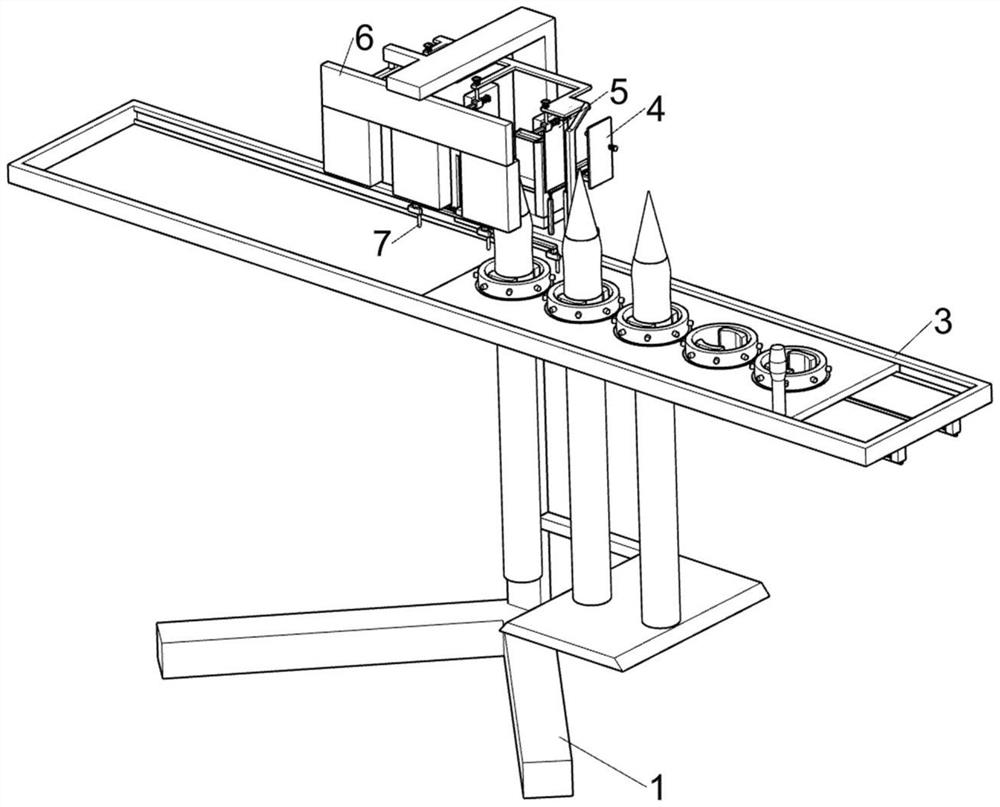

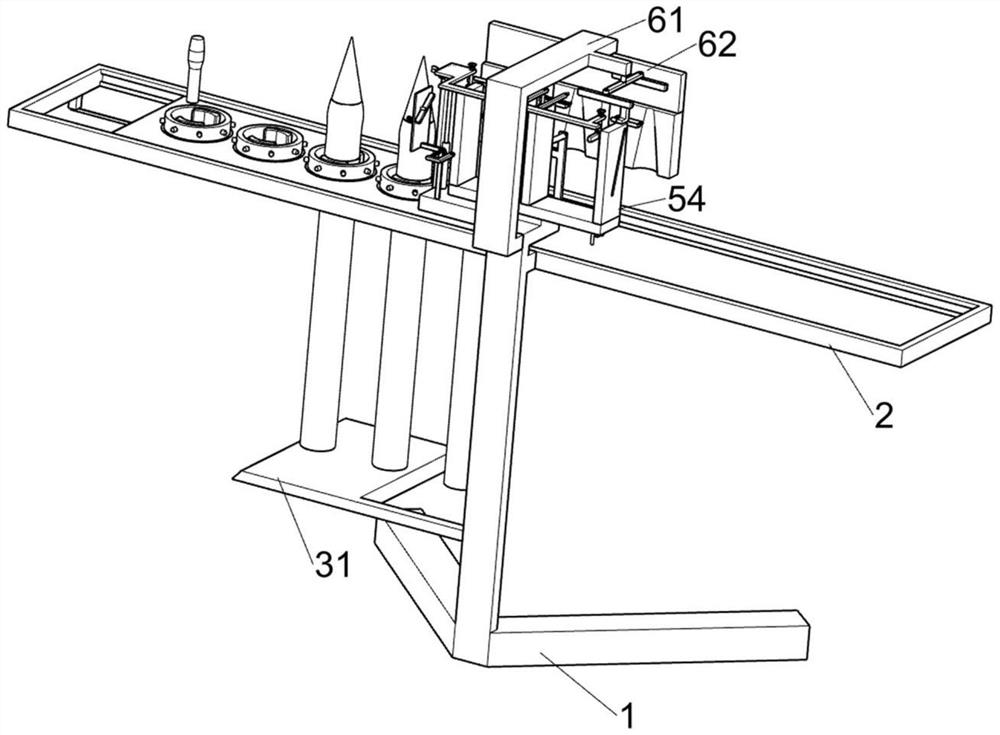

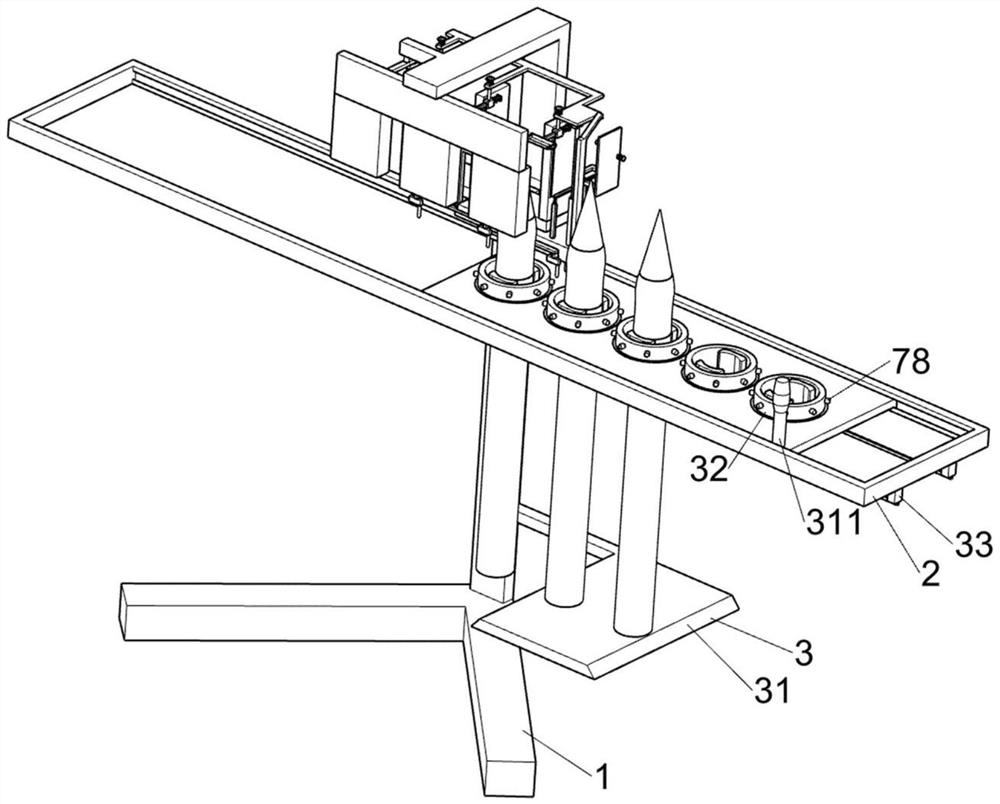

[0025] A reciprocating glue cleaning device for brush gluing, such as Figure 1-8 As shown, it includes a first support frame 1, a sliding support frame 2, a brush fixing assembly 3, a push assembly 4, a glue wiper assembly 5 and a brush limit assembly 6, and the first support frame 1 is fixed on the sliding support frame. 2. The writing brush fixing component 3 is arranged on the sliding support frame 2, and the pushing component 4 is arranged above the first supporting frame 1. The top of the first supporting frame 1 is slidably connected with a glue scraping brush assembly 5, which is used for the glue scraping brush assembly 5. In order to scrape off the glue on the tip of the brush, the brush limiting component 6 is arranged above the first support frame 1 , and the brush limiting component 6 is used to limit the brush.

[0026] The brush fixing assembly 3 includes a placing plate 31 , a sliding plate 311 , a rotating ring 32 , a spreading bar 33 , a clamping plate 34 and...

Embodiment 2

[0037] On the basis of Example 1, as Image 6 As shown, a rotating assembly 7 is also included. The first support frame 1 is slidably connected with a rotating assembly 7. The rotating assembly 7 is used to control the rotation of the rotating ring 32. The rotating assembly 7 includes a push rod 71 and a third sliding support frame 72. , the seventh spring 73, the rotating push frame 74, the second torsion spring 75, the guide bar 76, the third torsion spring 77 and the second clamping column 78, the second support frame 43 is fixed with a push rod 71, the first support frame 1 is slidably connected with a third sliding support frame 72 , a seventh spring 73 is connected between the third sliding support frame 72 and the first support frame 1 , and three rotating push frames 74 are connected in a distributed manner on the third sliding support frame 72 , the rotating push frame 74 is used to push the second clamping column 78, a second torsion spring 75 is connected between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com