Sailor's cap on the hat mouth bayonet mouthpiece

A technology of bayonet strips and sailor caps, applied in textiles and papermaking, cloth feeding mechanisms, cloth pressing mechanisms, etc., can solve the problems of no sailor caps, waste of time, waste of materials, etc., and is suitable for popularization and use and flexible operation , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

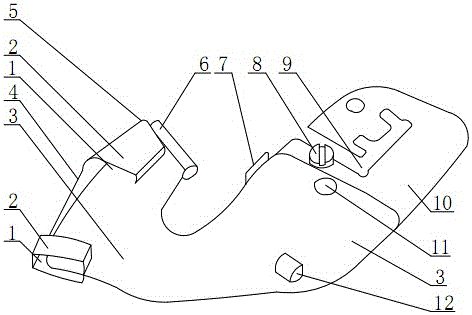

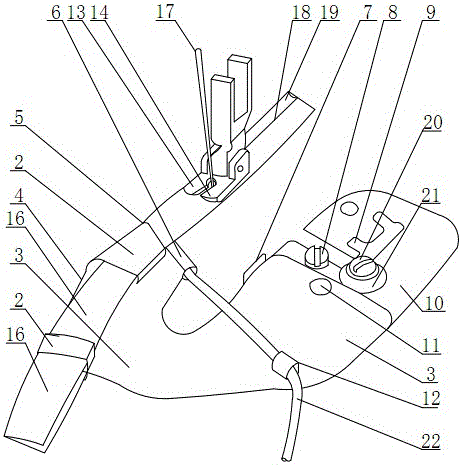

[0024] A mouthpiece with a bayonet on the top of a sailor's hat, see figure 1 , 2 , Shown in 3 and 4, comprise cloth arrangement mechanism and presser foot, cloth arrangement mechanism comprises cloth arrangement channel 1 and threading pipe 6. The cloth channel 1 is used for combing the cloth 16; the rope pipe 6 is used for combing the thread 22.

[0025] The left side of the cloth-arranging board 3 is provided with a cloth-arranging channel 1 whose cross-section is an inverted "U" shape, and the cloth-arranging channel 1 has a "U" shape in cross-section. ""-shaped cloth unpacking channel shell 2 and the cloth unscrambling plate 3 inserted into the cloth unscrambling channel shell 2 to the left are fixedly connected. The design of this cloth unscrambling channel 1 is convenient for combing the folded cloth 16, reducing the original bayonet The step of double-layer folding and ironing of the wrapping cloth is required in the production of strips, which saves the number of ...

Embodiment 2

[0034] A sailor cap with a bayonet mouthpiece, the difference from Embodiment 1 is that the outlet of the rope-threading pipe 6 is provided with an elbow with the outlet facing the cloth outlet direction.

Embodiment 3

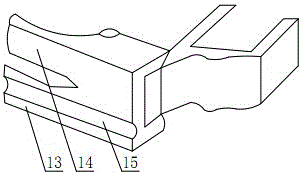

[0036] The utility model relates to a mouthpiece for a sailor cap with a bayonet mouth, which comprises a fabric unscrambling mechanism and a presser foot. The left side of the cloth-arranging board 3 is provided with a cloth-arranging channel 1 whose cross-section is an inverted "U" shape, and the cloth-arranging channel 1 has a "U" shape in cross-section. ”-shaped cloth arranging passage shell 2 and the cloth arranging board 3 inserted into the cloth arranging passage housing 2 to the left are fixedly connected to form. The cloth arranging board 3 is provided with a threading pipe 6, and the outlet of the threading pipe 6 is located at the outlet of the cloth arranging passage The left part of 5. The cloth arranging plate 3 is provided with holes, and the cloth arranging mechanism is fixed on the sewing machine worktable by the screws passing through the above-mentioned holes; There is a rope-pressing groove 15, and the direction of the rope-pressing groove 15 is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com