A feeding mechanism for brush carding robot

A feeding mechanism and robot technology, applied in the repair of ink pens, nibs, writing utensils, etc., can solve the problems of low efficiency and waste of manpower in manual carding, and achieve high carding efficiency and uniform carding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

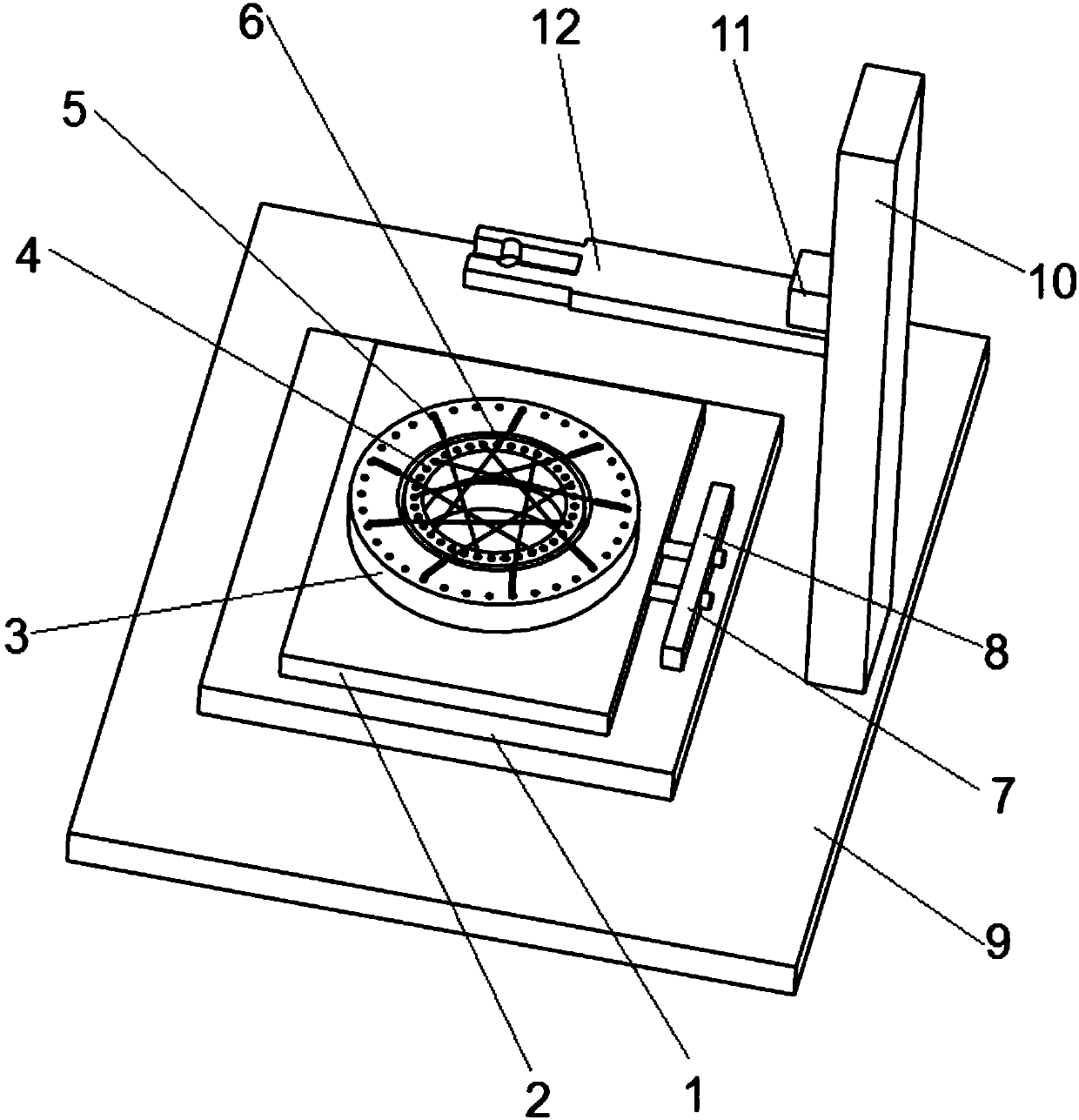

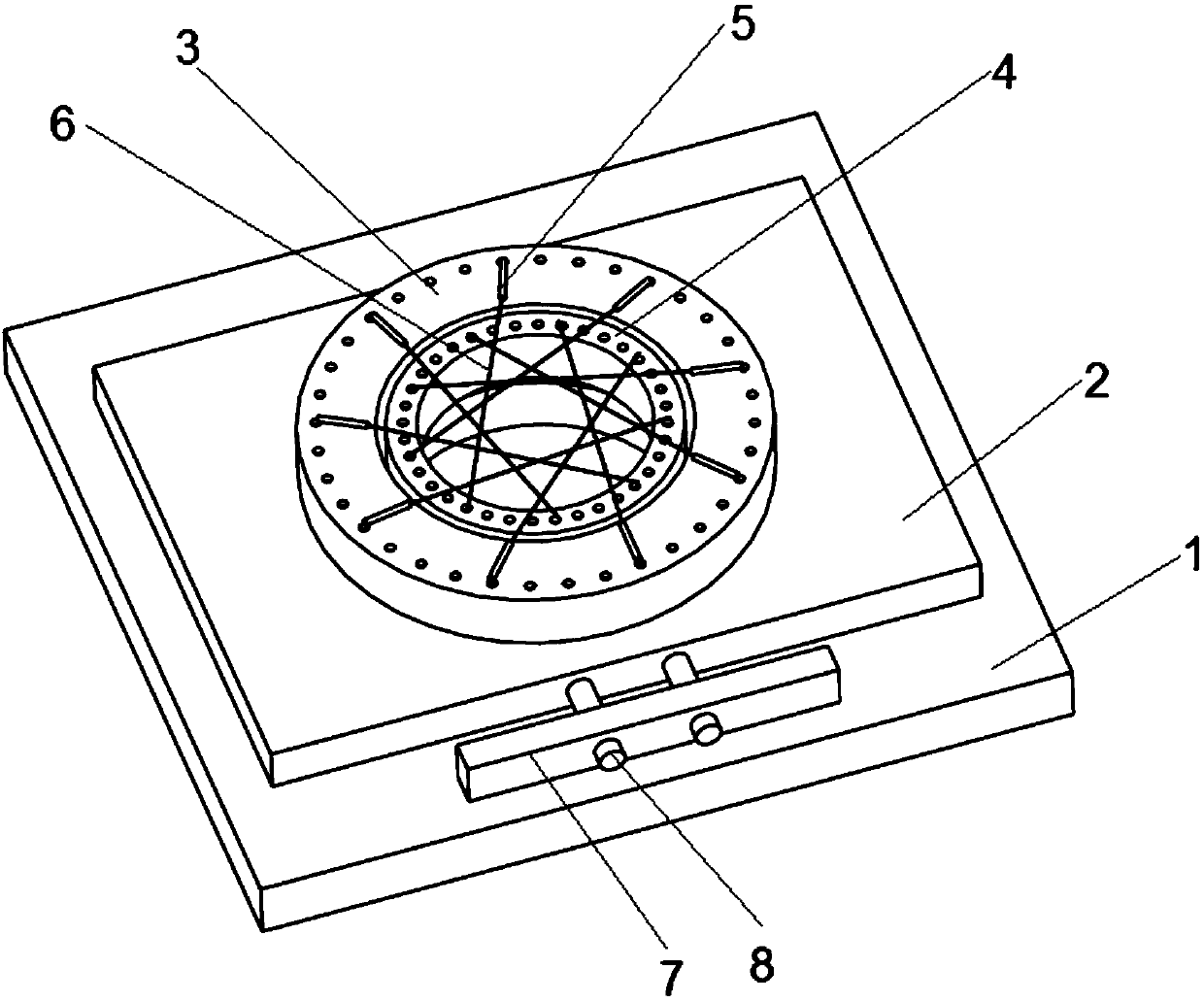

[0027] See figure 1 with figure 2 , A feeding mechanism for pen combing robot, with:

[0028] Fixed disk

[0029] The turntable is set in the middle of the fixed disk and can rotate;

[0030] Carding belt, the carding belt includes a spring and a rope. The spring and the rope have one end connected to each other, and the other ends are connected to the fixed disc and the turntable respectively;

[0031] The carding belt has at least three groups, which are distributed at different positions on the outer periphery of the fixed plate;

[0032] Conveying mechanism, including:

[0033] Upright

[0034] The sliding seat can slide up and down on the column; the power source can be an air cylinder or a hydraulic cylinder.

[0035] The clamping jaw is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com