Automotive plate and production method thereof

A production method and board technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of non-woven fabric size deformation, large deviation of board physical properties, difficult product physical properties, etc., and achieve simple processing technology , high strength, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

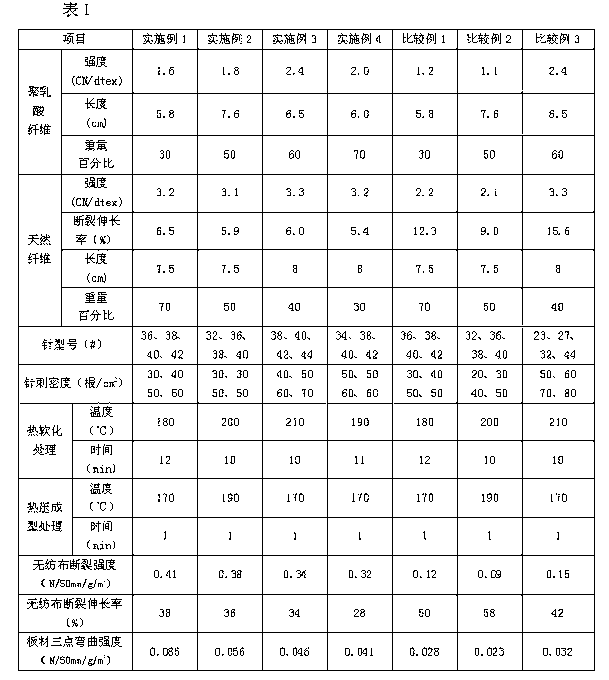

Embodiment 1

[0026] The strength is 1.6CN / dtex, the length is 5.8cm polylactic acid fiber and the strength is 3.2CN / dtex, the elongation at break is 6.5%, and the length is 7.5cm The kenaf fiber is mixed with a weight ratio of 30:70. The mixed fibers are put into the opening machine for opening and mixing, and then sent to the cotton box; the opened and mixed fibers stored in the cotton box are transported to the needle carding machine for carding; the carded fibers are sent to the web-laying machine Middle cross-laid net; the laid net is folded and sent to the needle punching machine to be needled into felt. The needle punching process adopts four reinforcement methods up and down, and the needle models of the four reinforcement methods are 36# and 38 respectively. #, 40#, 42#, the acupuncture density is 30 needles / cm 2 , 40 pieces / cm 2 , 50 pieces / cm 2 , 50 pieces / cm 2 , to obtain a natural fiber reinforced polylactic acid composite felt, that is, a natural fiber reinforced polylactic...

Embodiment 2

[0028]The strength is 1.8CN / dtex, length is 7.6cm polylactic acid fiber and strength is 3.1CN / dtex, elongation at break 5.9%, the length is 7.5cm Apocynum fiber is mixed with weight ratio as 50:50, will mix The good fibers are put into the opening machine for opening and mixing, and then sent to the cotton box; the opened and mixed fibers stored in the cotton box are transported to the needle carding machine for carding; the carded fibers are sent to the web-laying machine Cross-laid net; the laid net is folded and then sent to the needle punching machine for needle felting. The needle punching process adopts four reinforcement methods up and down, and the needle models of the four reinforcement methods are 32# and 36# respectively. , 38#, 40#, the acupuncture density is 30 needles / cm 2 , 30 pieces / cm 2 , 50 pieces / cm 2 , 50 pieces / cm 2 , to obtain a natural fiber reinforced polylactic acid composite felt, that is, a natural fiber reinforced polylactic acid nonwoven fabric,...

Embodiment 3

[0030] The strength is 2.4CN / dtex, the length is 6.5cm polylactic acid fiber and the intensity is 3.3CN / dtex, the elongation at break is 6.0%, the abaca fiber that length is 8cm is mixed with weight ratio as 60:40, will mix The good fibers are put into the opening machine for opening and mixing, and then sent to the cotton box; the opened and mixed fibers stored in the cotton box are transported to the needle carding machine for carding; the carded fibers are sent to the web-laying machine Cross-laid net; the laid net is folded and sent to the needling machine for pre-needling to form a felt. The needling processing method adopts four reinforcement methods up and down, and the needle models of the four reinforcement methods are 38# and 40 respectively. #, 42#, 44#, the acupuncture density is 40 needles / cm 2 , 50 pieces / cm 2 , 60 pieces / cm 2 , 70 pieces / cm 2 , to obtain a natural fiber reinforced polylactic acid composite felt, that is, a natural fiber reinforced polylactic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com