Used paper diaper processing method and used paper diaper processing device

A processing method and technology of a processing device are applied in the field of used paper diaper processing and used paper diaper processing device, which can solve the problems of large installation space, difficult and difficult installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] used disposable diaper disposal device 1

[0101] 〔Composition of the device〕

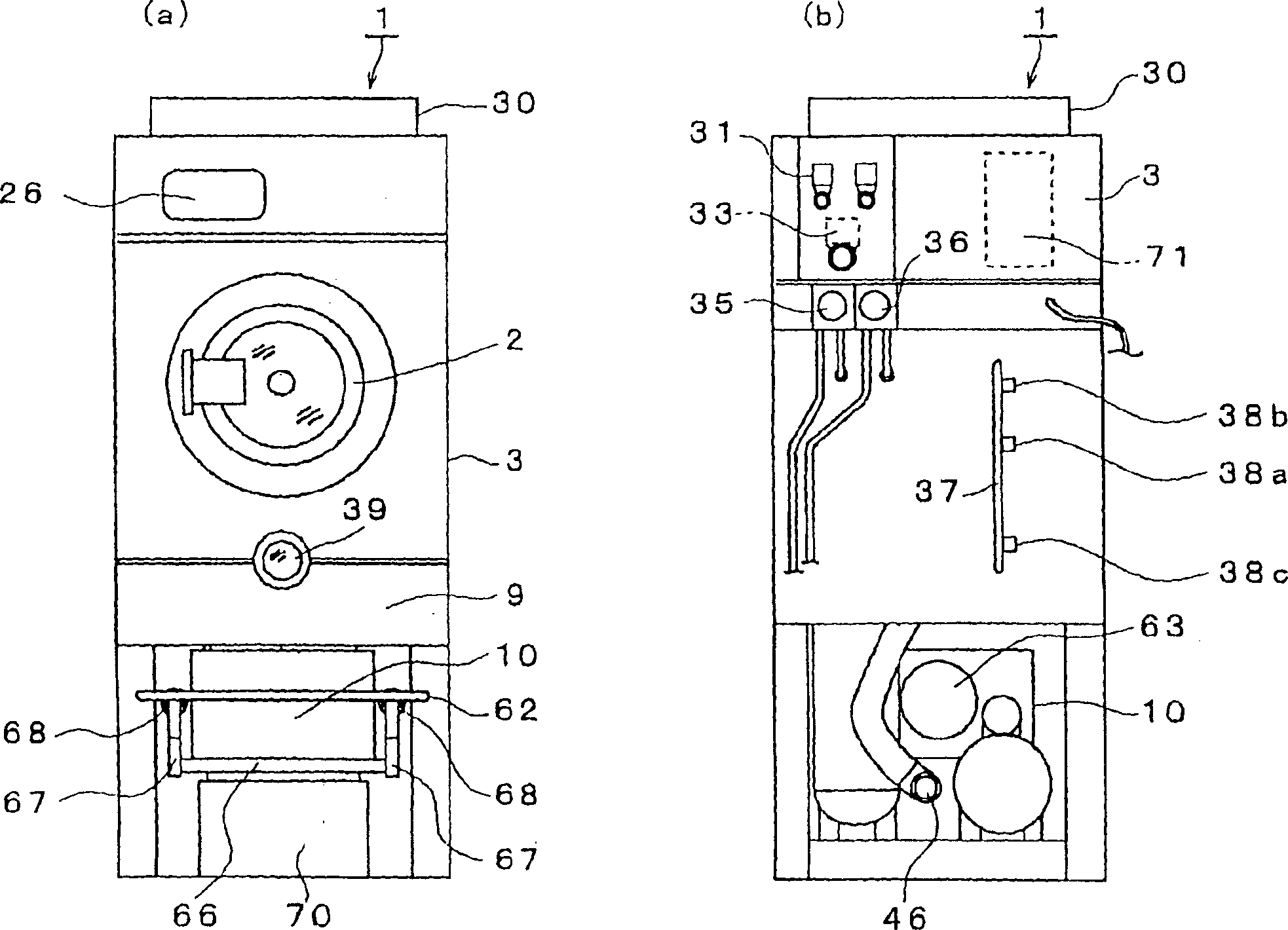

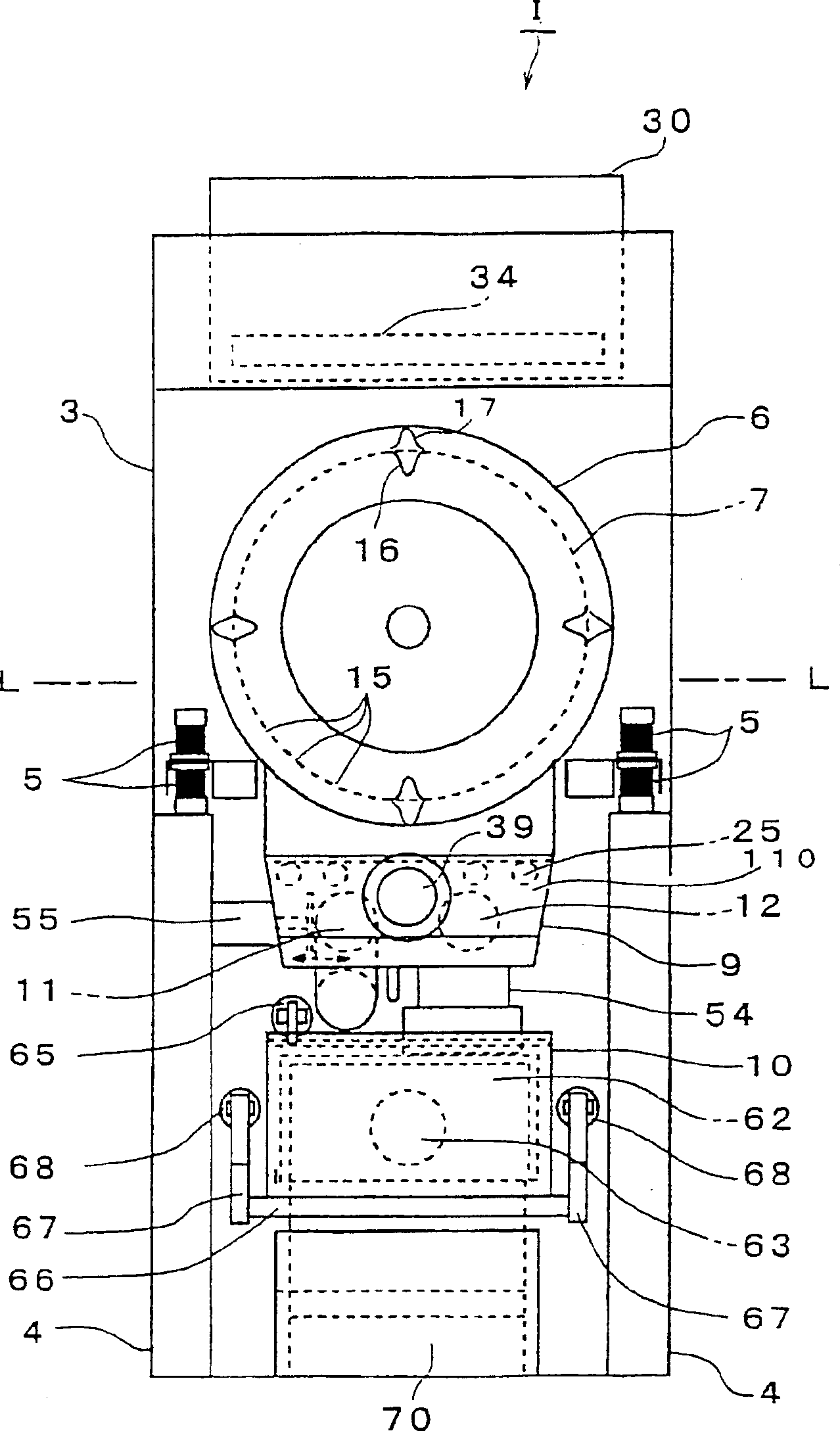

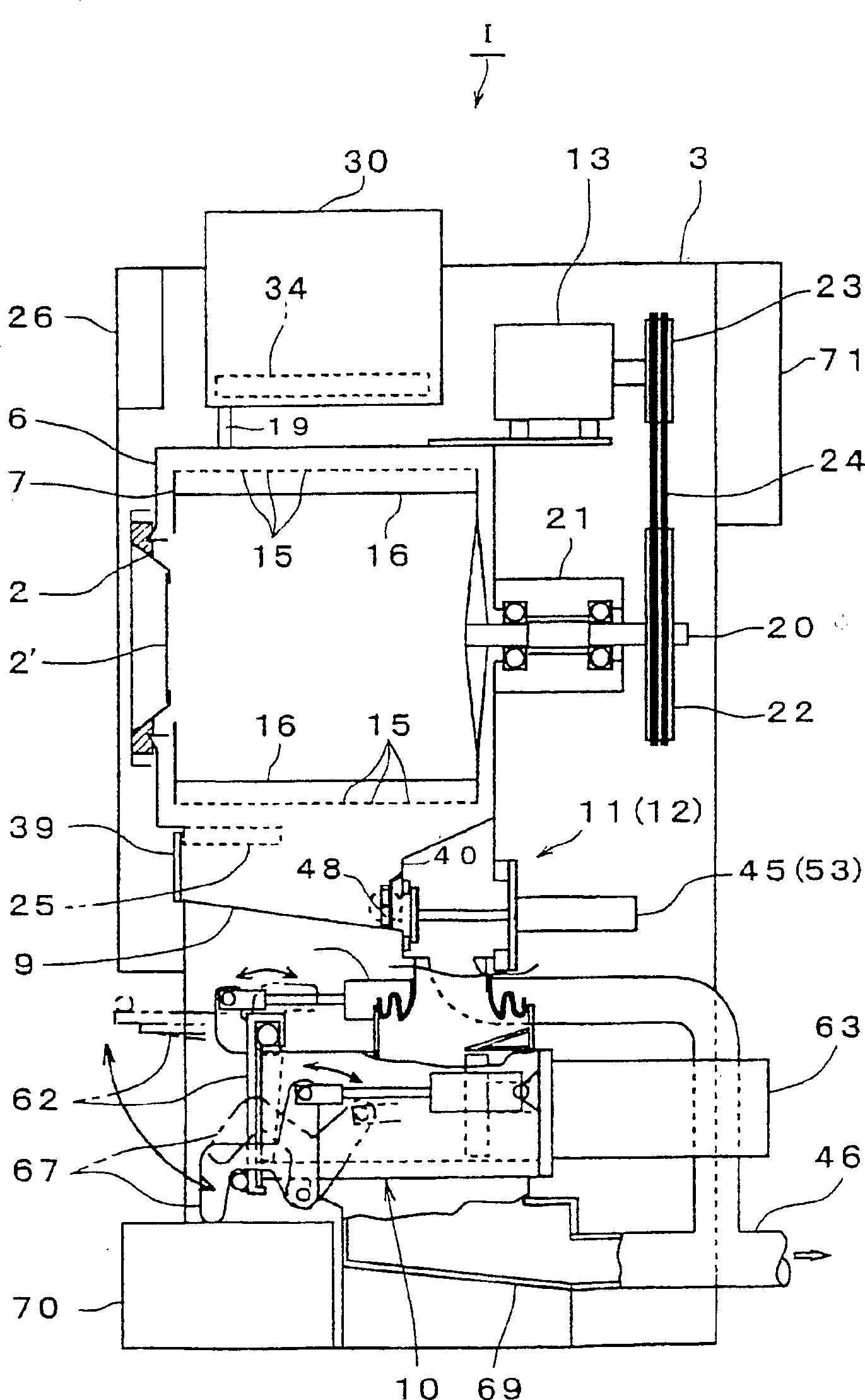

[0102] figure 1 (a) is a front view of an example of the disposable diaper disposal device 1, figure 1 (b) is its rear view, figure 2 is a schematic diagram of the internal structure viewed from the front, image 3 It is a sectional view of the internal structure seen from the right side.

[0103] The disposable diaper disposal device 1 has: an outer cylinder 6 provided on a base 4 with a vibration absorbing material 5 interposed therebetween inside a frame body 3 having an opening and closing door 2 on the front; , the rotating drum 7 that accommodates used paper diapers; the storage tank 9 that is arranged at the bottom of the outer cylinder 6 and can accommodate the disassembled absorbent material and dirt of the disassembled paper diapers; Filtration and separation mechanism 10; treatment liquid supply means 19 for supplying the treatment liquid to the outer cylinder 6; filter dis...

Embodiment 2

[0164] Used disposable diaper disposal device II

[0165] 〔Composition of the device〕

[0166] The front view and rear view of the used diaper disposal unit II are the same as the used diaper disposal unit I, as shown in figure 1 (a), figure 1 (b) shown. On the other hand, a schematic diagram of the internal structure of the used paper diaper disposal device II viewed from the front is shown in Image 6 As shown, the cross-sectional view of the internal structure of the used paper diaper disposal device II viewed from the right side is shown in Figure 7 shown.

[0167] As shown in these figures, the disposable diaper disposal device 1 of the present embodiment is briefly composed of a frame 3 with an opening and closing door 2 on the front, and is provided on a base 4 with a vibration absorbing material 5 interposed therebetween. The outer cylinder 6; the rotating drum 7 that can be freely rotatably arranged in the outer cylinder 6 at predetermined intervals and accommo...

Embodiment 3

[0213] Used disposable diaper disposal device III

[0214] 〔Composition of the device〕

[0215] Figure 9 It is a side sectional view which shows the internal structure of still another form of a disposable diaper disposal apparatus.

[0216] like Figure 9 As shown, the disposable diaper disposal apparatus 1 of the third embodiment is different from the used diaper disposal apparatus II of the second embodiment in that the filter liquid discharge means 140 is arranged at the rear lower part of the outer tube 6 .

[0217] Specifically, the first branch pipe 463 with the above-mentioned overflow liquid drainage means 120 is branched and connected to the main drainage pipe 46 extending toward the sewage treatment facility side, and the filter liquid drainage means 140 is arranged on the branch connected to the first branch pipe 46. On the upstream side base end portion 464a of the second branch pipe 464 on the branch pipe 463, the upstream side base end portion 464a is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com