Combine

A combine harvester and body technology, applied in the direction of harvesters, cutters, mechanical equipment, etc., can solve problems such as damage and decrease in durability, and achieve the effects of improving durability, preventing grain clogging and promoting drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the first embodiment of the present invention will be described in detail with reference to the drawings. In addition, for ease of understanding, directions are shown for ease of description, but the structure is not limited to this.

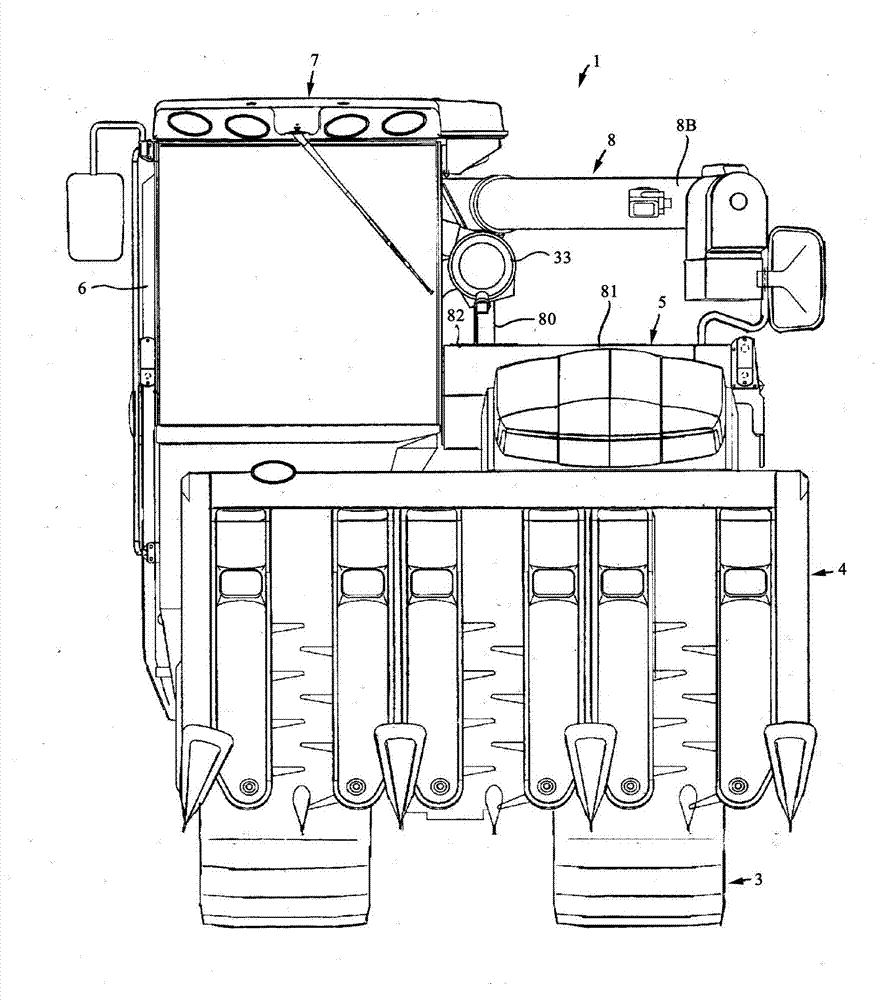

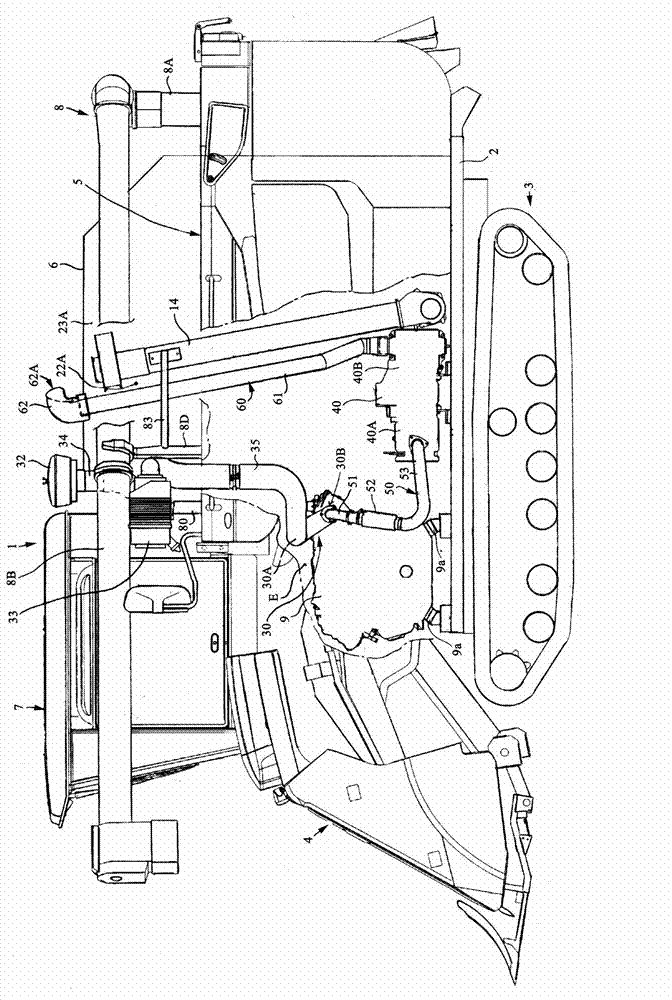

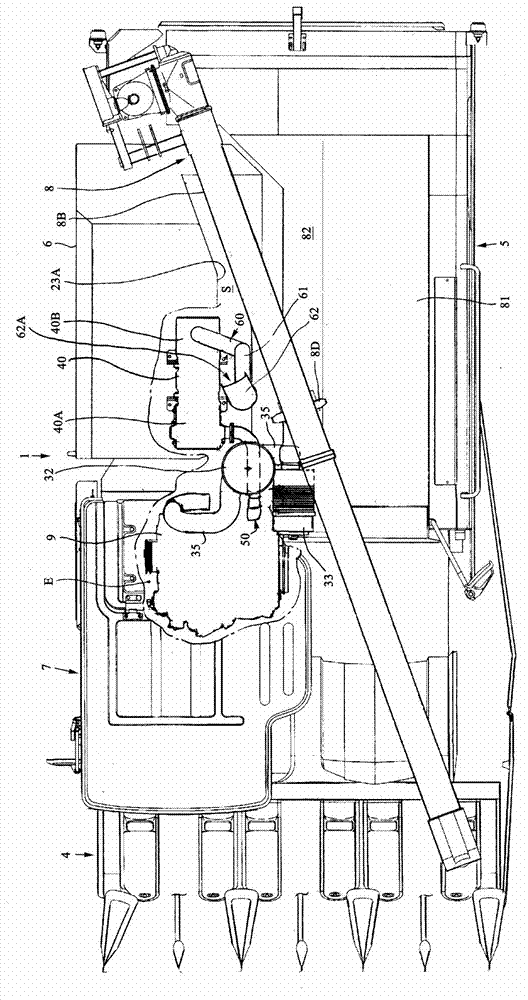

[0053] Such as Figure 1 ~ Figure 4 As shown, the combine harvester 1 is equipped with: a traveling device 3 consisting of a pair of left and right crawlers walking in the farmland; a harvesting device 4 that harvests grain stalks from the farmland at the front end of the machine body; behind it, the grain stalks are threshed and screened The threshing device 5; and a grain container 6 for storing threshing and sieved grains arranged side by side on the right side of the threshing device 5. The front side of the grain container 6 faces the back of the harvesting device 4, and is provided for operation The driver’s cab 7.

[0054] In addition, the rear side of the grain container 6 is provided with a discharge auger 8 that dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com