Method for coating material application to substrate and device for coating material application

A coating method and technology for coating devices, which are applied to devices for coating liquid on surfaces, metal material coating processes, coatings, etc., can solve the problem of uneven coating thickness, uneven coating, and lack of hydrophilicity. and other problems, to achieve the effect of easy coating operation, improved productivity, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] [Embodiments of Paint Coating Method and Paint Coating Apparatus to Substrate]

[0070] The paint coating method and paint coating apparatus for a base material of the present invention can coat base materials used in various fields. An example of the paint coating method and paint coating apparatus of the present invention will be described below.

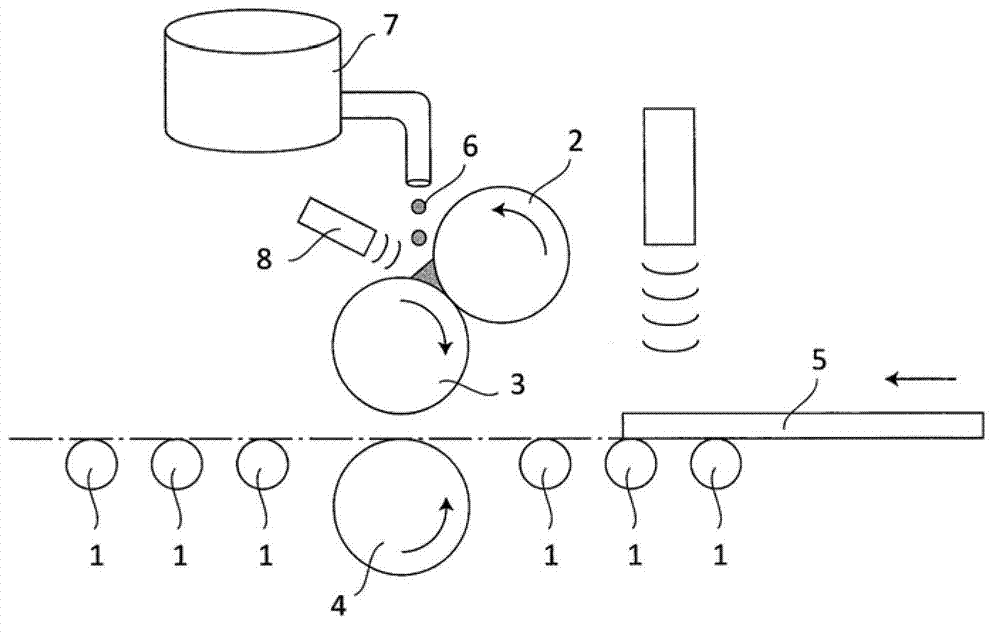

[0071] like figure 1 As shown, the coating coating device of the present invention has a guide roll 1 , a coating amount control roll 2 , a coating roll 3 and a support roll 4 . In this coating device, the rotation of the guide roller 1 guides the substrate 5 in the direction of the arrow ( figure 1 The left side of ) is conveyed, and when conveyed to the top of the backup roller 4, the coating 6 is coated on the top of the substrate 5 with the coating roller 3.

[0072] In the method of coating a coating material on a base material of the present invention, the above-mentioned coating device can be used, but other coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com