Kitchen wastewater oil-water separation device

A technology of oil-water separation device and kitchen waste water, which is applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc. It can solve the problems of complex structure of oil-water separator, cumbersome and complicated gas source system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

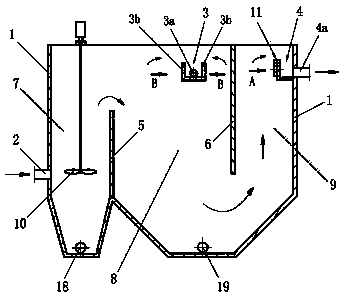

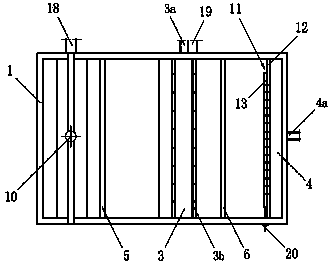

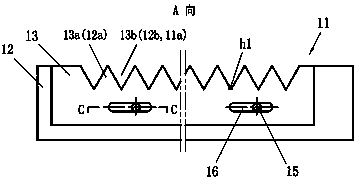

[0052] See attached picture.

[0053] The present invention includes a housing 1, an oil collecting tank 3 and a water collecting tank 4. There is a water inlet pipe 2 on the wall of the housing 1, the oil collecting tank 3 has an oil outlet 3a, and the water collecting tank 4 has a water outlet 4a; the housing 1 shown in the figure is a cuboid structure.

[0054] The shell 1 is provided with a first vertical plate 5 and a second vertical plate 6, and the first oil-water separation area 7, the second oil-water separation area 8, and the water collection area 9 are sequentially formed in the shell 1; The top of the first oil-water separation zone 7 communicates with the top of the second oil-water separation zone 8, i.e. the waste water passage; the bottom of the second oil-water separation zone 8 communicates with the bottom of the catchment area 9, i.e. the water flow channel;

[0055] The bottom of the first oil-water separation zone 7 is a lower cone structure, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com