Bio-organic fertilizer raw material stirring device capable of uniformly stirring

A bio-organic fertilizer and uniform stirring technology, which is applied to mixers, mixer accessories, mixers and other directions with a rotating mixing device, can solve the problem of reducing the practicability of the mixing device, blocking the surface of the filter net, and reducing the cleaning convenience inside the mixing device, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

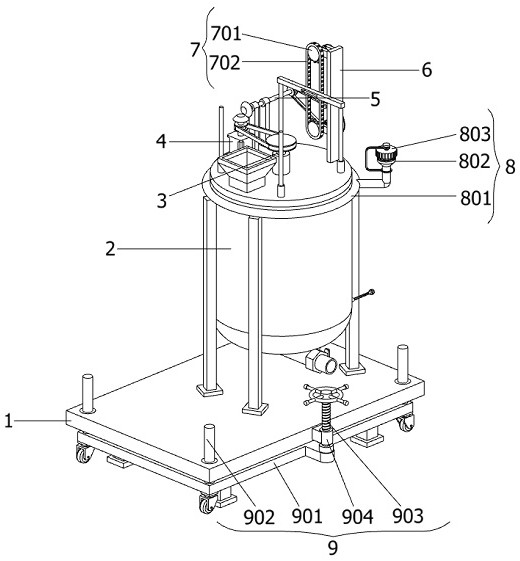

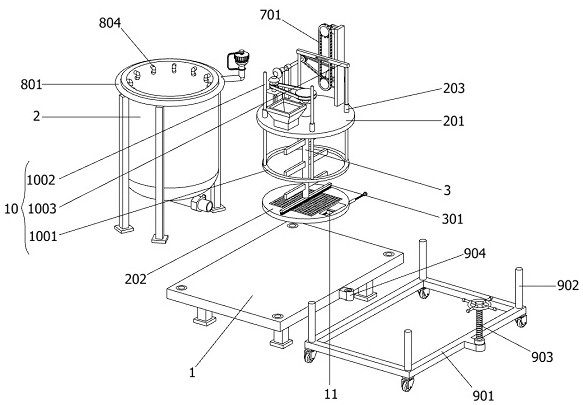

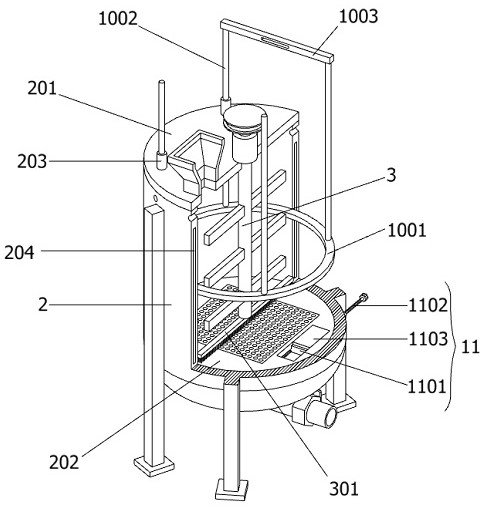

[0032]Appendfigure 1 AdherentFigure 7Down:

[0033]The present invention provides a bio-organic fertilizer raw material mixing apparatus that is stirred, including: moving base 1, moving base 1, moving base 1, can be mounted on the right side, can body 2 including top cover 201, filter plate 202, limited sliding The cylinder 203 and the heating sheet 204, the top cover 201 is provided with a top cover 201, and the inside of the can body 2 is provided with a filter plate 202, and the filter plate 202 is fixed to the upper surface of the filter, and the upper end surface of the filter plate 202 is opened. The opening, and the front and rear sides of the rectangular opening are open, and the upper end surface of the top cover 201 is provided with a ring array in the upper surface of the tank, and the can body 2 is provided with a heating sheet 204, tank. 2 There is a discharge opening at the bottom, and a valve is attached to the discharge port; the center of the can body 2 is rotated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com