Water-permeable ground system and pavement method

A ground system and permeable technology, applied in the direction of pavement details, roads, road repair, etc., can solve problems such as poor water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

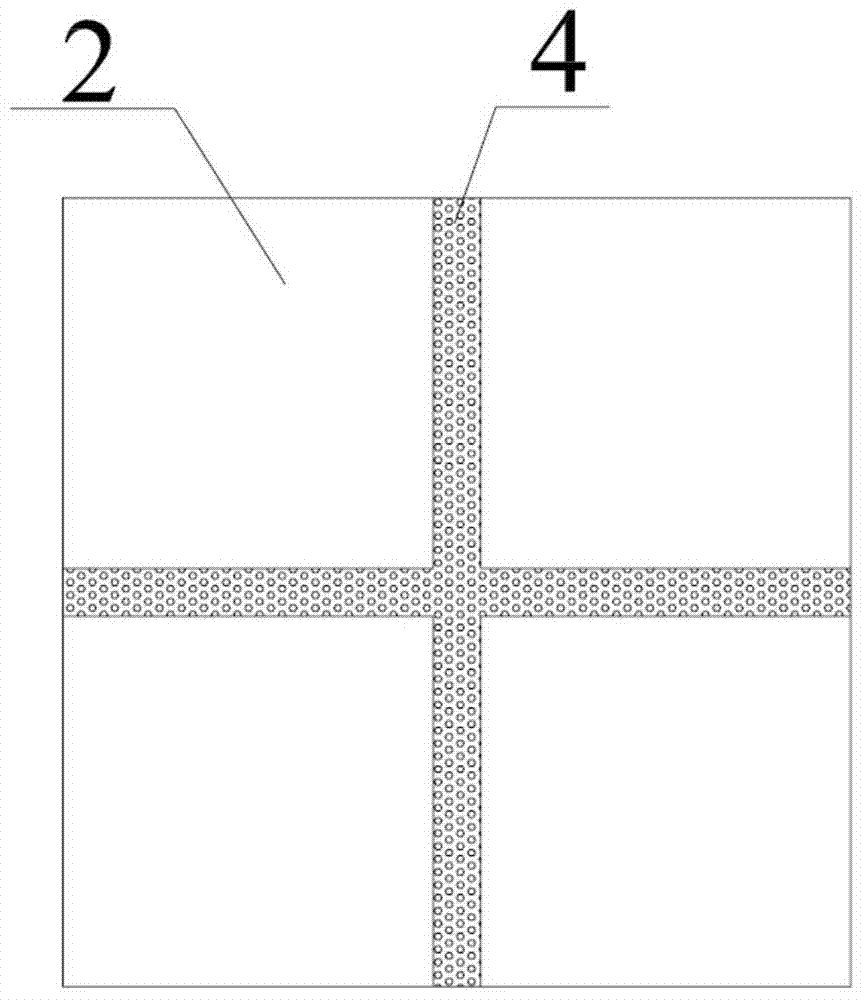

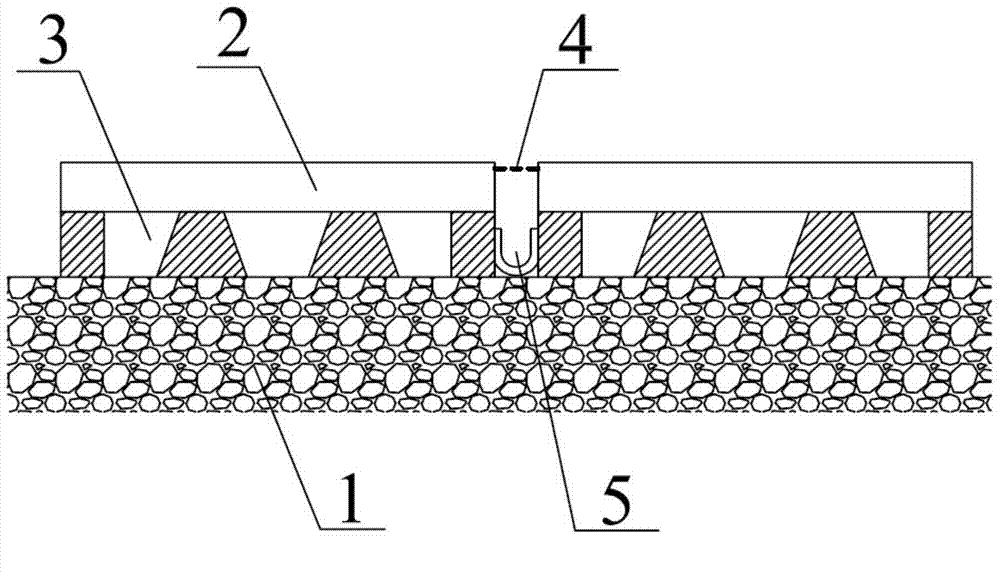

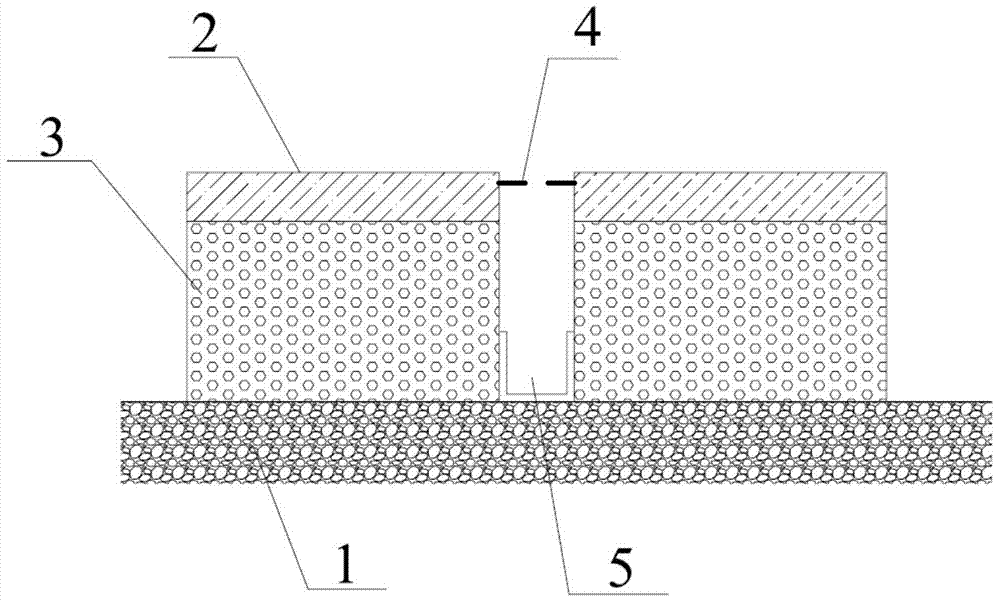

[0044] figure 1 A top view of a water-permeable ground system provided by an embodiment of the present invention; figure 2 A cross-sectional view of a water-permeable ground system provided by an embodiment of the present invention; image 3 A cross-sectional view of a water-permeable ground system provided by an embodiment of the present invention; Figure 4 A block flow diagram of a pavement method for a permeable ground provided in an embodiment of the present invention; Figure 1-4 As shown, a water-permeable ground system provided in this embodiment includes a water-permeable base layer 1, and a plurality of decorative modules are arranged on the water-permeable base layer 1;

[0045] The decorative module includes a decorative surface layer 2, the bottom of the decorative surface layer 2 is provided with a support layer 3, the support layer 3 is connected to the permeable base layer 1, and gaps are provided between adjacent decorative modules, and a permeable module i...

Embodiment 2

[0050] figure 1 A top view of a water-permeable ground system provided by an embodiment of the present invention; figure 2 A cross-sectional view of a water-permeable ground system provided by an embodiment of the present invention; image 3 A cross-sectional view of a water-permeable ground system provided by an embodiment of the present invention; Figure 4 A block flow diagram of a pavement method for a permeable ground provided in an embodiment of the present invention; Figure 1-4 As shown, a water-permeable ground system provided in this embodiment includes a water-permeable base layer 1, and a plurality of decorative modules are arranged on the water-permeable base layer 1;

[0051] The decorative module includes a decorative surface layer 2, the bottom of the decorative surface layer 2 is provided with a support layer 3, the support layer 3 is connected to the permeable base layer 1, and gaps are provided between adjacent decorative modules, and a permeable module i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com