Rapid water seepage concrete and preparation method thereof

A concrete and fast technology, applied in the field of concrete, can solve the problems of low water seepage speed, weak wear resistance, weak pressure bearing capacity, etc., to achieve smooth pore water seepage, improve mechanical strength, and avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of fast permeable concrete: it comprises the following steps:

[0030] Step 1, weigh 80 parts of water, 30 parts of Portland cement, 50 parts of gravel, 4 parts of stearyl chloride, 5 parts of sulfamate-based high-efficiency water reducer, 5 parts of non-agglomerating steel fiber and coupling agent 0.5 copies;

[0031] Step 2, put water, portland cement and non-agglomerated steel fibers into the mixing tank for stirring; the stirring rate is 50 rpm, stirring for 10 minutes;

[0032] Step 3, put crushed stone, stearyl chloride, sulfamate-based high-efficiency water reducer and coupling agent into the stirring tank for stirring; the stirring rate is 100 rpm, stirring for 30 minutes;

[0033] Step four, discharge.

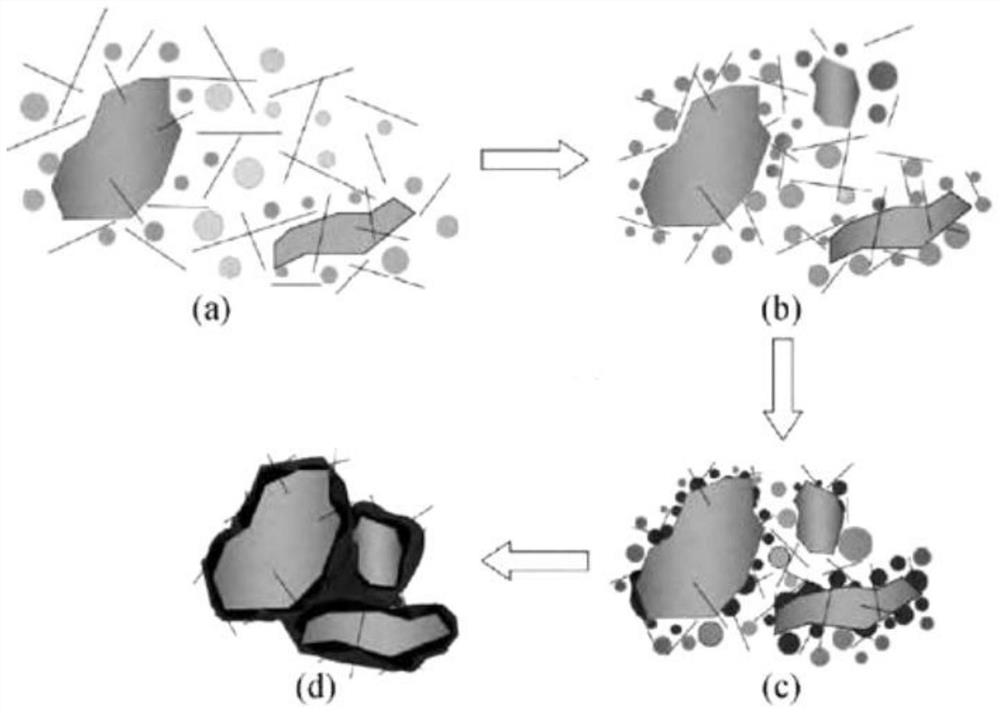

[0034] The preparation method of described non-clustering steel fiber comprises the following steps:

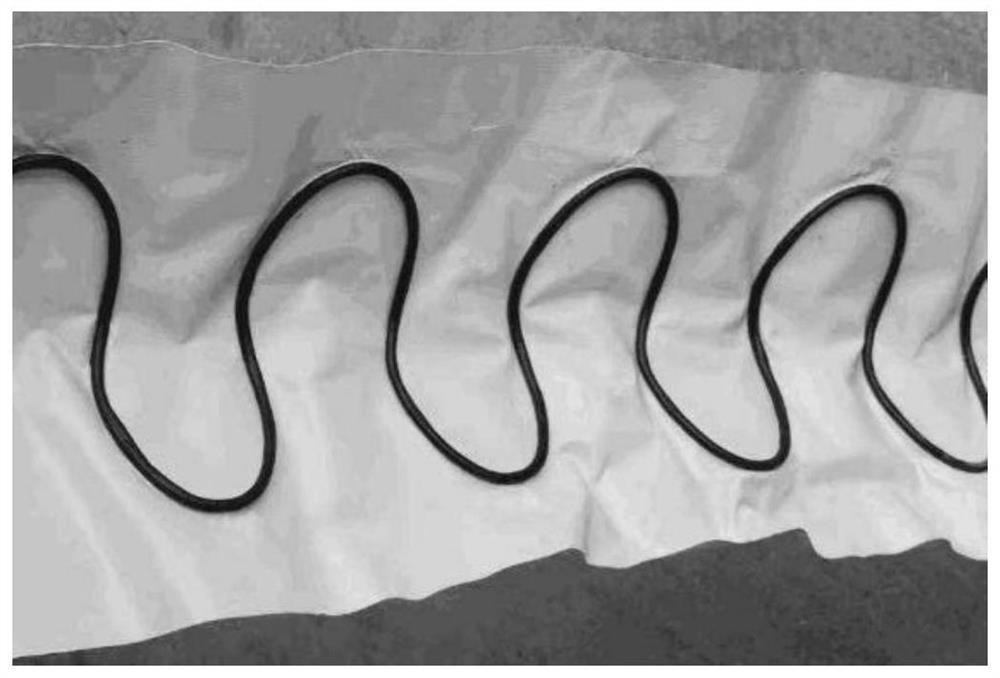

[0035] S1 extruder extrudes wavy steel wire;

[0036] S2 Place the steel wire on the nylon paper cut into strips, and fix the...

Embodiment 2

[0044] A kind of preparation method of fast permeable concrete: it comprises the following steps:

[0045] Step 1, weigh 80 parts of water, 30 parts of Portland cement, 50 parts of gravel, 4 parts of stearyl chloride, 5 parts of sulfamate-based high-efficiency water reducer, 5 parts of non-agglomerating steel fiber and coupling agent 0.5 copies;

[0046] Step 2, put water, portland cement and non-agglomerated steel fibers into the mixing tank for stirring; the stirring rate is 50 rpm, stirring for 10 minutes;

[0047] Step 3: Put gravel, octadecanoyl chloride, sulfamate-based high-efficiency water reducer and coupling agent into the mixing tank for stirring, and at the same time put 5 parts of glass fiber into it; the stirring rate is 100 rpm, and stir for 30 minutes ;

[0048] Step four, discharge.

[0049] The preparation method of described non-clustering steel fiber comprises the following steps:

[0050] S1 extruder extrudes wavy steel wire;

[0051] S2 Place the ste...

Embodiment 3

[0054] A kind of preparation method of fast permeable concrete: it comprises the following steps:

[0055] Step 1, weigh 80 parts of water, 30 parts of Portland cement, 50 parts of gravel, 4 parts of stearyl chloride, 5 parts of sulfamate-based high-efficiency water reducer, 5 parts of non-agglomerating steel fiber and coupling agent 0.5 copies;

[0056] Step 2, put water, portland cement and non-agglomerated steel fibers into the mixing tank for stirring; the stirring rate is 50 rpm, stirring for 10 minutes;

[0057] Step 3: Put gravel, octadecanoyl chloride, sulfamate-based high-efficiency water reducer and coupling agent into the mixing tank for stirring, and at the same time put 7 parts of glass fiber and 2 parts of fluorescent pigment; the stirring speed is 100 rpm minutes, stirring for 30 minutes;

[0058] Step four, discharge.

[0059] The preparation method of described non-clustering steel fiber comprises the following steps:

[0060] S1 extruder extrudes wavy ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com