Gas turbine control method and controller

By setting up a database and exploration control unit in the gas turbine, adjusting fuel and air flow, and predicting load changes, the problem of multi-frequency band combustion vibration is solved, the combustion stability and design state are maintained, and the operating efficiency and life of the gas turbine are improved. .

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] First, using the Figure 12 , The sectional view used to explain the general composition of the burner is Figure 13 The gas turbine 2 will be briefly described. Should Figure 12 The gas turbine 2 shown has: a compressor 22 having an inlet guide vane 26; The combustion gas introduction pipe 38 supplies combustion gas to the turbine 24 and discharges the combustion gas to the outside through piping.

[0050] The rotation of the turbine 24 is transmitted to the compressor 22 through the rotary shaft 39, and the external intake air 25 is taken in from the intake port provided with a filter to generate compressed air, and the compressed air is supplied to the burner 23 from the compressed air introduction part 27 for combustion. For the inlet guide vane 26 provided in the compressor 22, the angle of the rotor vane 26 of the inlet guide vane 26, that is, the valve opening is controlled by the rotary vane on the air introduction side of the compressor 22, so that even if...

Embodiment 2

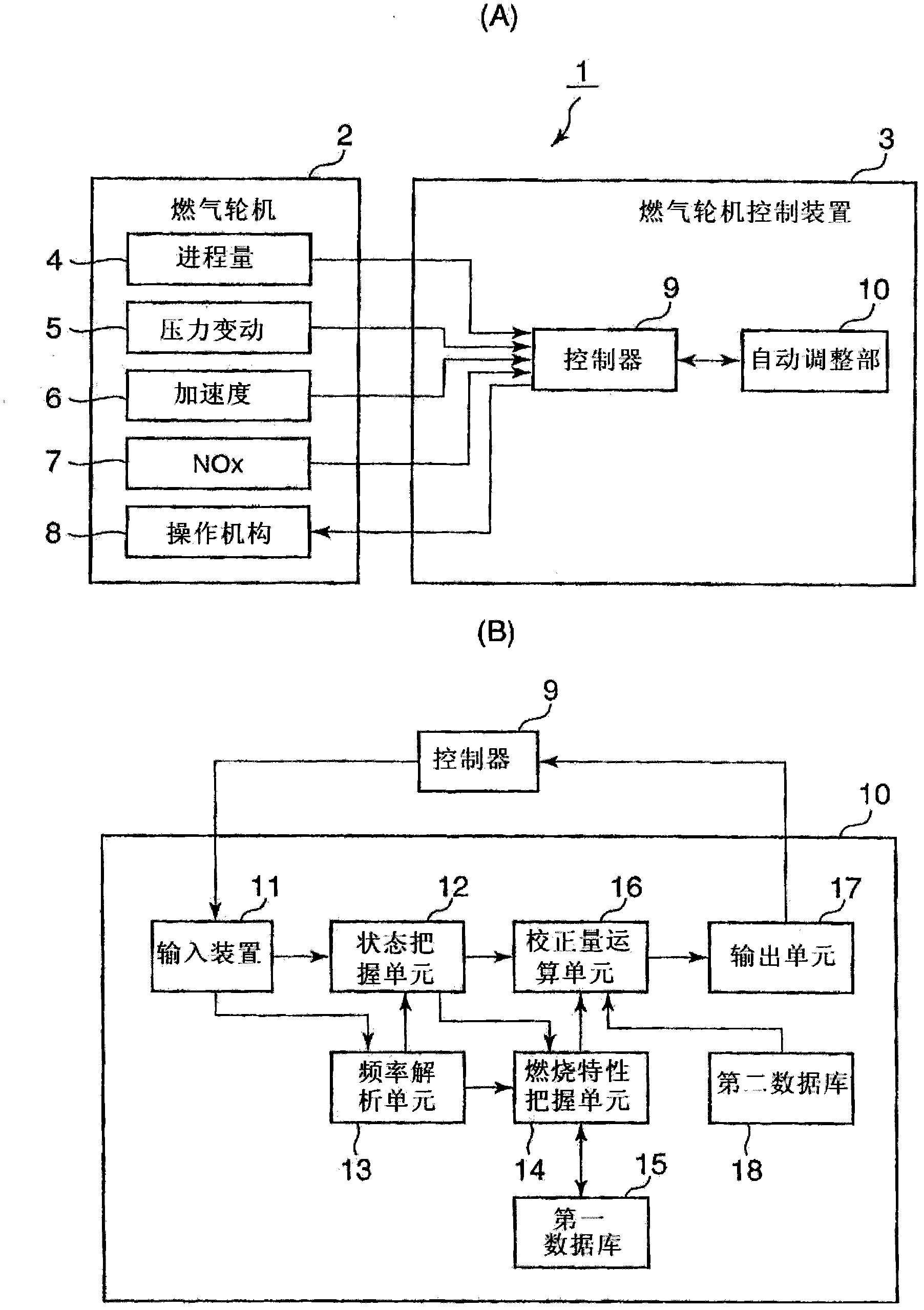

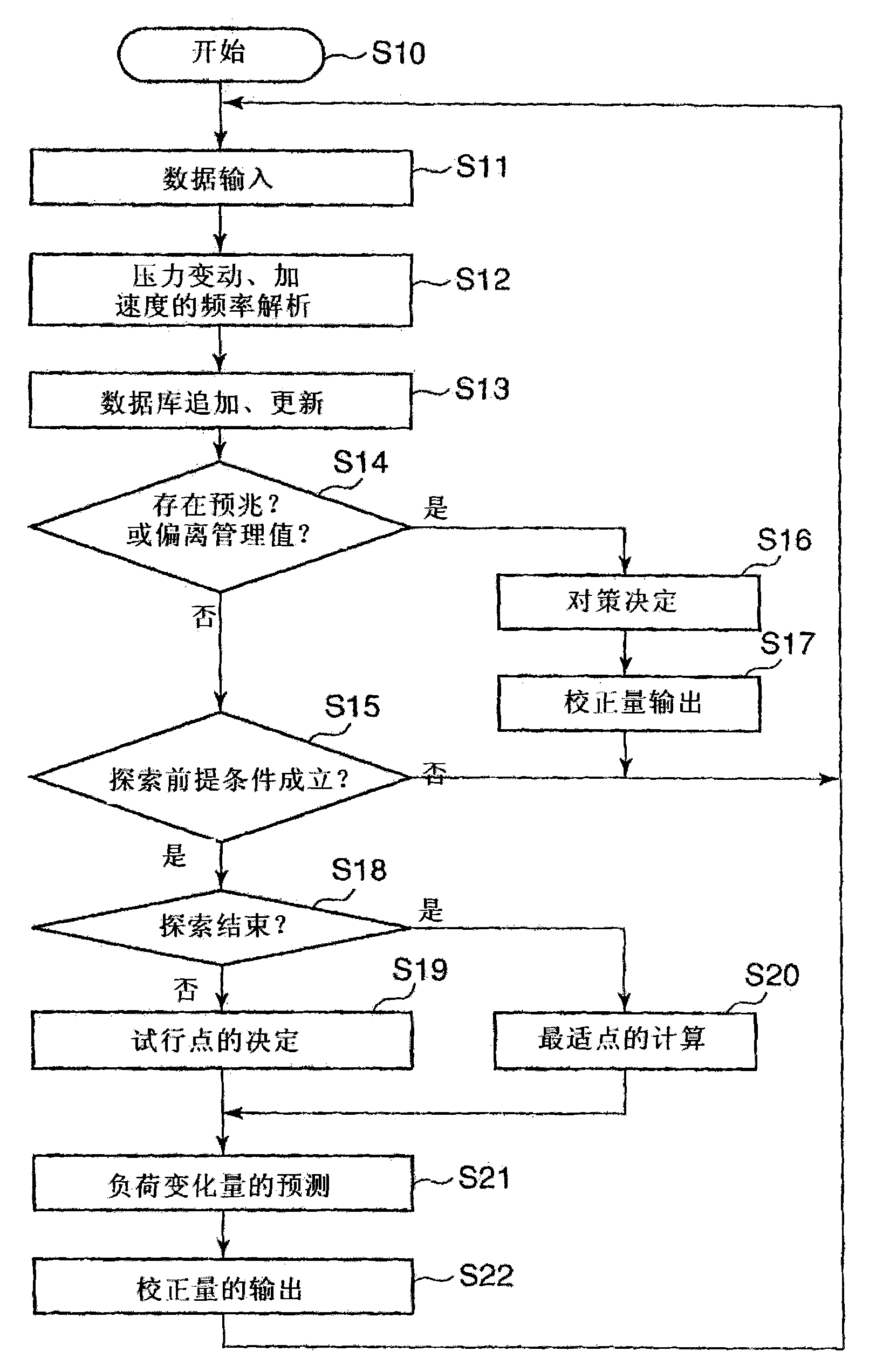

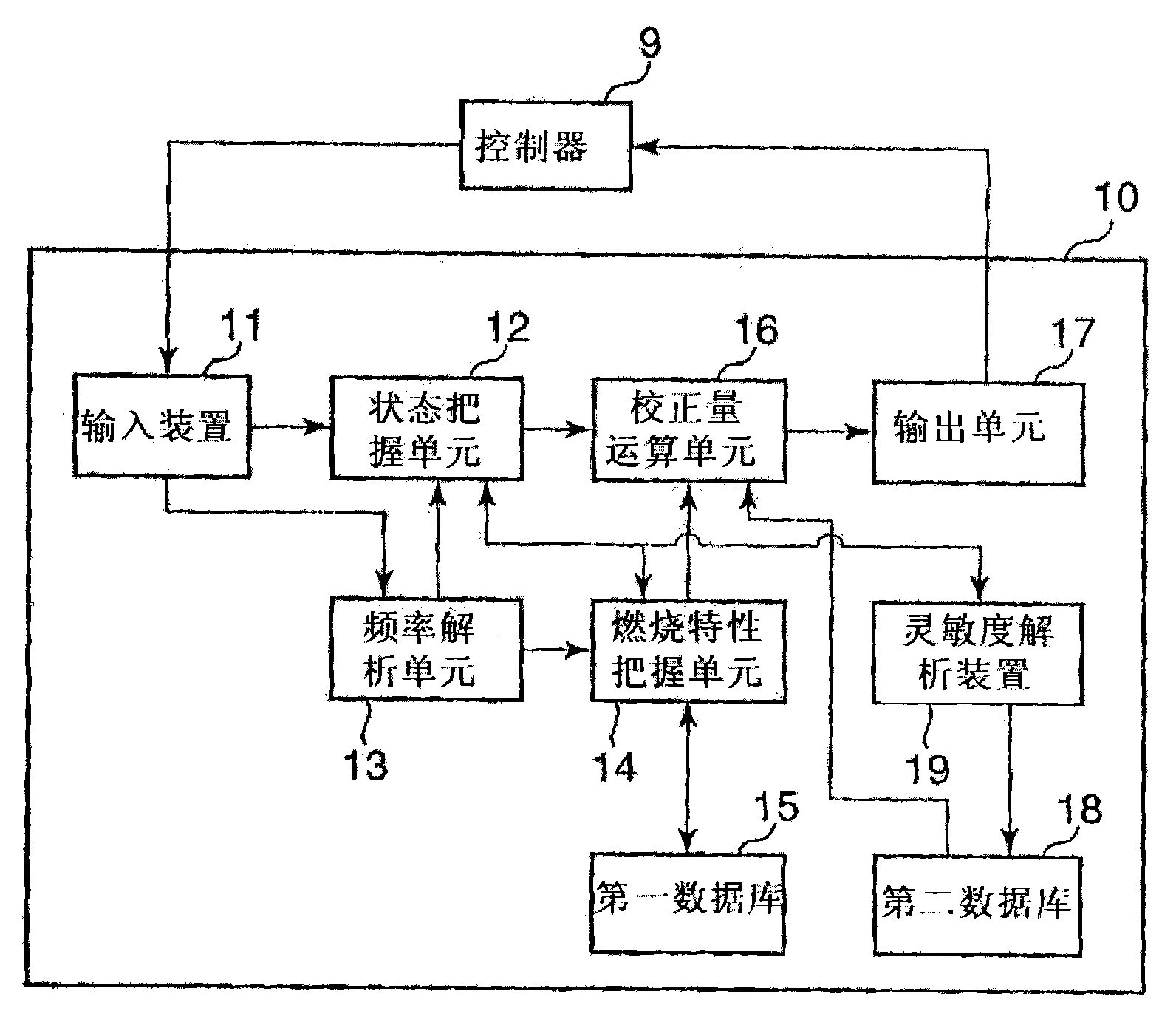

[0125] Next, use image 3 , Figure 4 , Figure 9 Example 2 of the present invention will be described. image 3 is to implement the gas turbine control method of the present invention figure 1 The block diagram of the device shown in (A), the detailed block diagram of the embodiment 2 of the automatic adjustment unit 9, Figure 4 is a flowchart of Embodiment 2 of the gas turbine control method of the present invention, Figure 9 This is an example of the configuration of the database used in Embodiment 2 of the present invention.

[0126] In the first embodiment described above, the load sensitivity data is collected by preliminaries such as trial operation, and the value obtained by this is stored in the second database 18 for use. However, in this method, it is necessary to manually calculate the sensitivity and store it, and since the content will not change unless the data is re-collected and rewritten, even if the performance of the compressor deteriorates or the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com