Exhaust purification device for internal combustion engine

一种排气净化装置、内燃机的技术,应用在排气装置、排气处理装置的电控、排气处理装置的诊断装置等方向,能够解决难以完全防止微粒过滤器熔损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

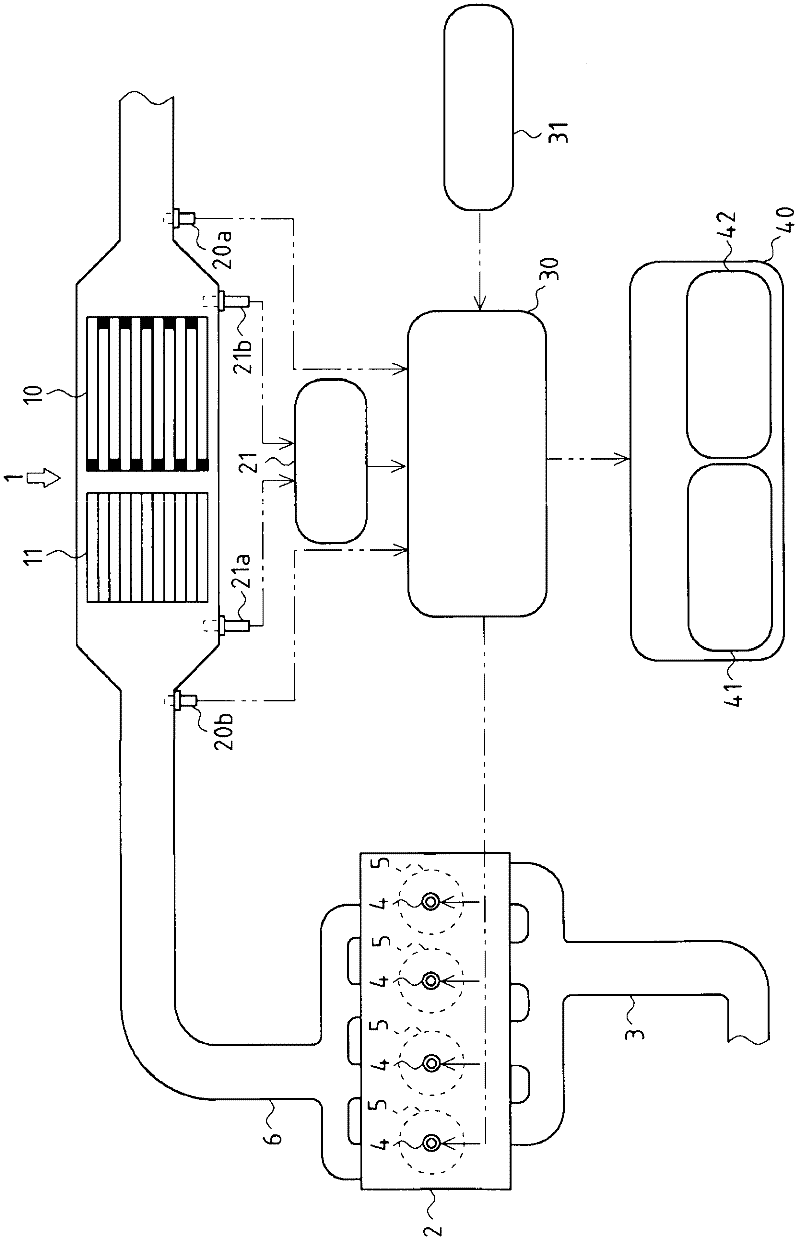

[0023] Below, use figure 1 An exhaust gas purification device 1 as an embodiment of the exhaust gas purification system of an internal combustion engine according to the present invention will be described.

[0024] Such as figure 1 As shown, the exhaust gas purification device 1 is used to purify and discharge the exhaust gas generated in the internal combustion engine 2 . The exhaust purification device 1 is provided in an internal combustion engine 2, and has a particulate filter 10, an oxidation catalyst 11, a downstream side temperature sensor 20a as an exhaust temperature detection means, a filter temperature sensor 20b as a filter temperature detection means, and an exhaust gas temperature sensor 20b as an exhaust gas temperature detection means. The exhaust pressure difference detection device 21 as pressure difference detection means, the ECU 30 as a control means, the notification device 40 as a notification means, and the like.

[0025] The internal combustion eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com