Chamfering and tapping machine for cover plate

A technology of tapping machine and cover plate, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low tapping processing efficiency, and achieve the effect of eliminating repeated processing, improving consistency, and efficient and stable feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

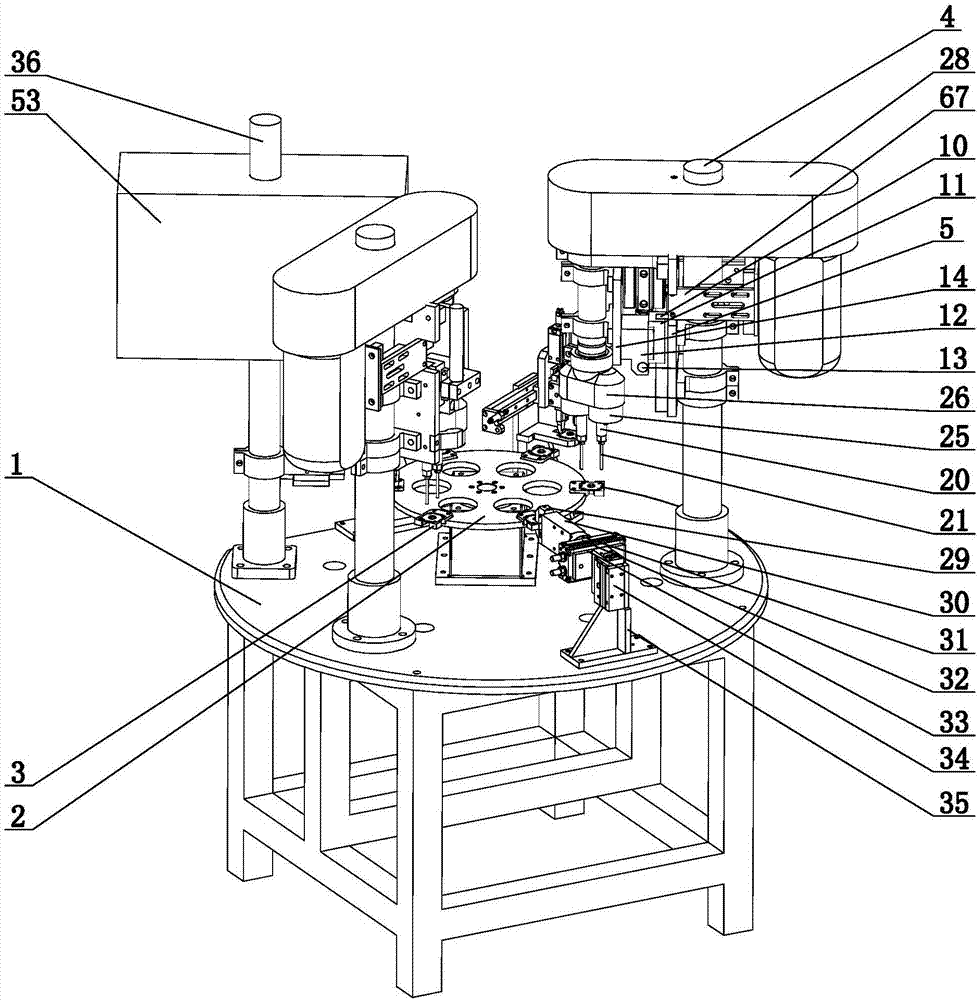

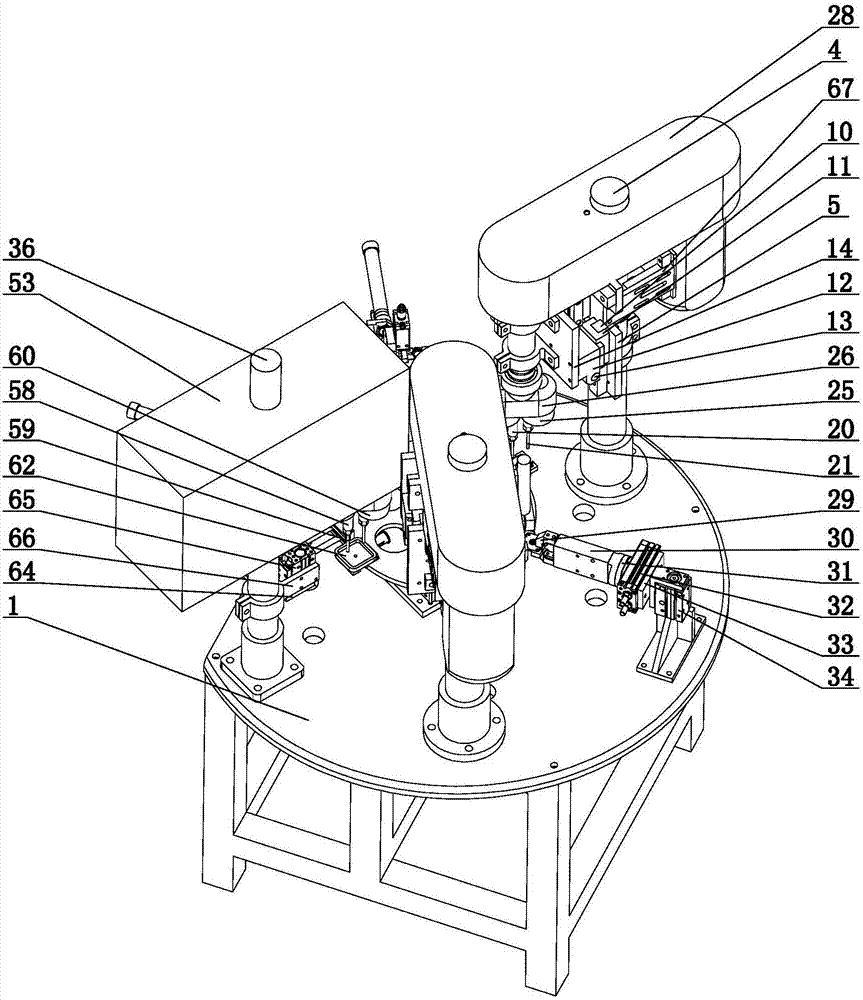

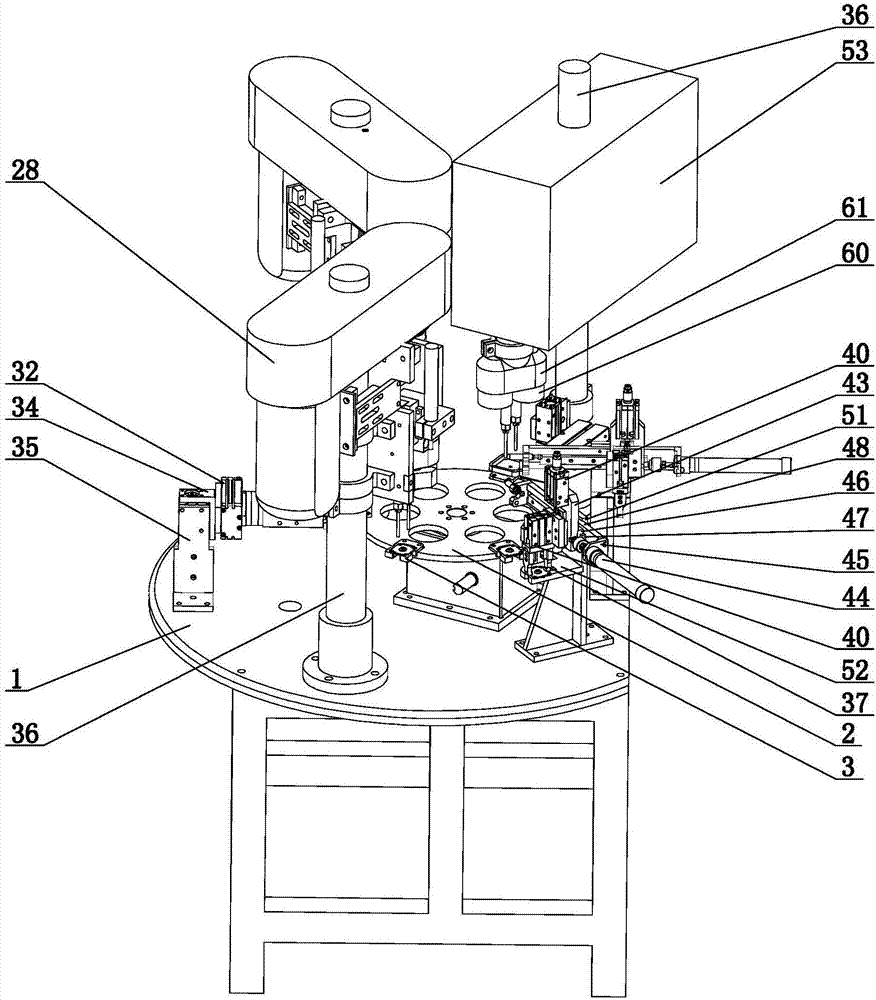

[0035] Such as Figure 1~17 The chamfering tapping machine for a cover plate shown includes a bottom platform 1, which is circular as a whole, and has a straight edge on the side of the cover plate blanking machine structure, which is convenient for erecting a receiving container. There is a turntable structure in the middle of the surface of table 1. The turntable structure includes a turntable 2 and a divider. The turntable 2 is rotated and set on the divider. The turntable 2 is installed on the output shaft of the divider. One end of the divider input shaft is connected to the stepping motor of the turntable. , the other end of the input shaft of the divider is connected to a signal wheel, the signal wheel rotates once, and the outer diameter gradually changes from small to large, a sensor is provided on one side of the signal wheel, and a signal is provided to the sensor at the largest outer diameter of the signal wheel, and the input force The shaft rotates one circle, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com