In-mold injection mold for integrally molding refrigerator decorative bar

A technology for in-mold injection molding and refrigerator trim, applied in the direction of coating, etc., can solve problems such as product process defects, high assembly costs, and low efficiency, and achieve the effects of reducing mold manufacturing costs, reducing injection molding production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

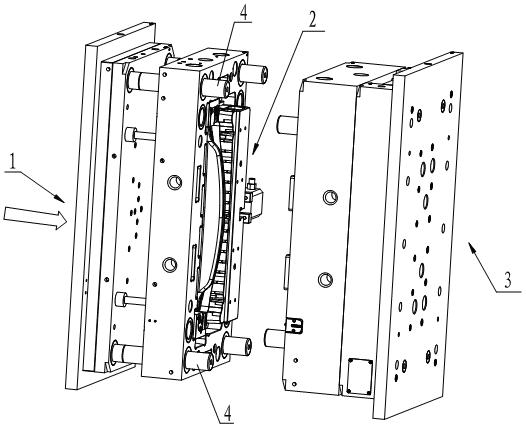

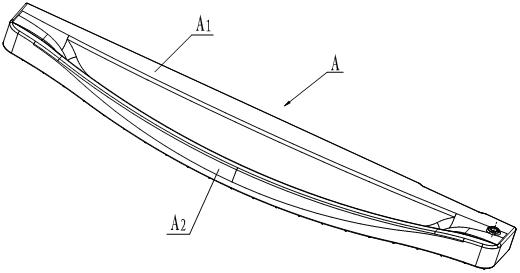

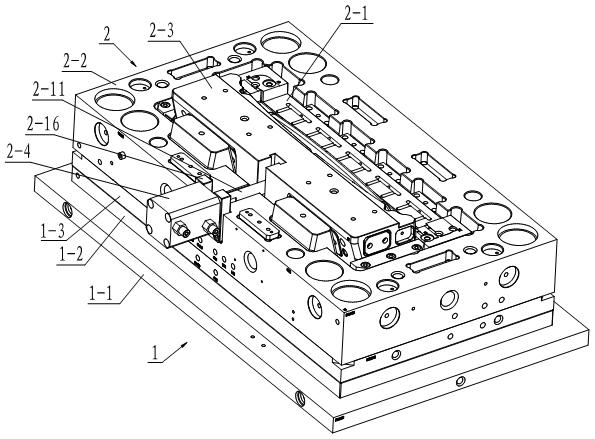

[0019] In this embodiment, the in-mold injection mold for the integrated molding of the refrigerator decorative strip is used for the integrated in-mold injection molding such as figure 2 The refrigerator trim A shown is the trim body A 1 and diaphragm trim A 2 Integral molding, diaphragm decoration A 2 Located in trim body A 1 on the side. The mold is along the injection molding direction, i.e. figure 1 The direction indicated by the middle arrow includes the static mold assembly 1, the positioning and locking assembly 2, and the moving mold assembly 3. In this embodiment, the trim body A 1 The upper surface of the mold is molded on the static mold assembly 1, the lower surface is molded on the movable mold assembly 3, and the diaphragm decoration A 2 In trim body A 1 The side of the film, after the film, the decorative strip body A 1 The upper surface of the refrigerator decorative strip A forms the entire appearance surface.

[0020] like figure 1 , Figure 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com