Manufacturing method of V-type-channel microchannel plate

A technology of microchannel plate and manufacturing method, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems, and can solve problems such as loss of gain, contact surface damage, and reduction of gain amplification coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

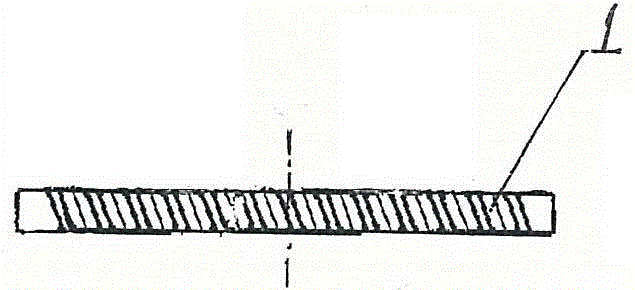

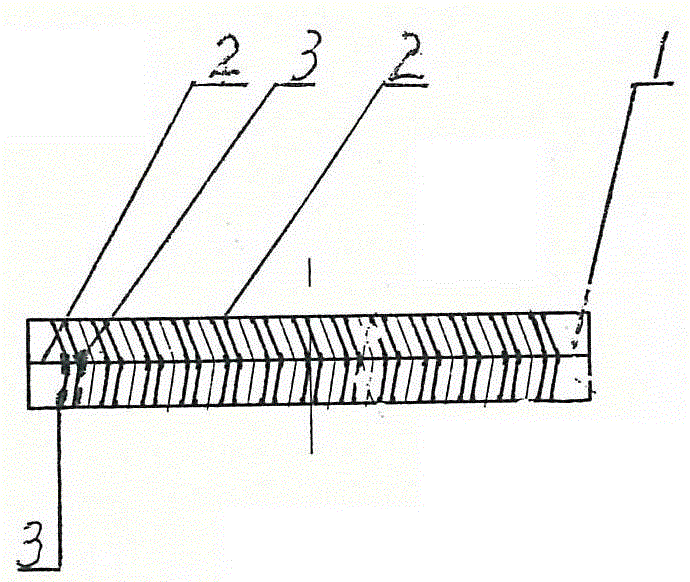

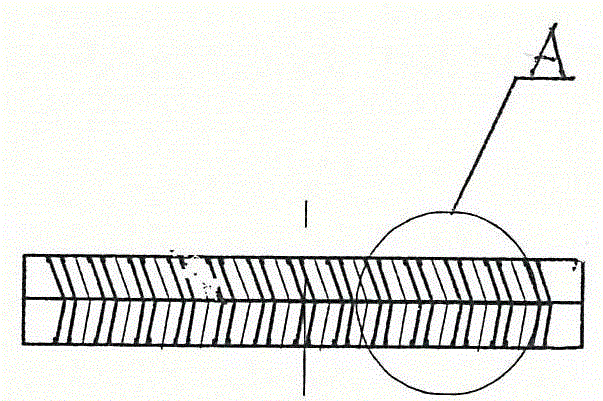

Image

Examples

Embodiment 1

[0026] Embodiment 1, taking the outer diameter of the MCP whiteboard as F25mm, the channel aperture as 8 μm, the bevel angle as 6 °, and the thickness as an example of the thermal bonding process operation steps of the V-channel microchannel plate production: other steps are the same, so The difference is that in step c, the first piece of MCP whiteboard is put into the sunken table of the graphite base 5, the depth X of the sunken table is 0.6 mm, and the diameter is Φ25.1 mm; in step f, the graphite sheet A stainless steel load 7 weighing 20 g is lightly placed on the upper surface of 6; in step g, the temperature control process is to raise the temperature of the vacuum furnace to 512° C. within 1 hour.

Embodiment 2

[0027] Embodiment 2, taking the outer diameter of the MCP whiteboard as F33mm, the channel aperture as F10μm, the bevel angle as 6°, and the thickness as the V-shaped channel microchannel plate as an example. The operation steps of the thermal bonding process: other steps are the same, so The difference is that in step c, the first piece of MCP whiteboard is put into the sunken table of the graphite base 5, the depth X of the sunken table is 0.8 mm, and the diameter is Φ33.1 mm; in step f, the graphite sheet A stainless steel load 7 weighing 45g is lightly placed on the upper surface of 6; in step g, the temperature control process is to raise the temperature of the vacuum furnace to 515° C. within 1 hour.

Embodiment 3

[0028] Embodiment three, take the outer diameter of MCP whiteboard as Φ20mm, the channel aperture as F6mm, the bevel angle as 6°, and the thermal bonding process operation steps of the production of V-shaped channel microchannel plate as example: other steps are the same, so The difference is that in step c, the first piece of MCP whiteboard is put into the sunken table top of graphite base 5, with a diameter of Φ20.1 mm; in step f, a weight of 8g of stainless steel load 7; in step g, the temperature control process is to raise the temperature of the vacuum furnace to 510° C. within 1 hour.

[0029] Except for the three embodiments above, the present invention is also used for thermal bonding of MCP whiteboards of various other specifications and models to produce V-shaped channel microchannel plates required for low-light image intensifiers and photomultiplier tubes, all of which can satisfy The demand for the product it belongs to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com