Quick grouting device and grouting method thereof

A fast, grouting hole technology, applied in the direction of construction, infrastructure engineering, etc., to achieve the effect of eliminating scrap, reducing labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

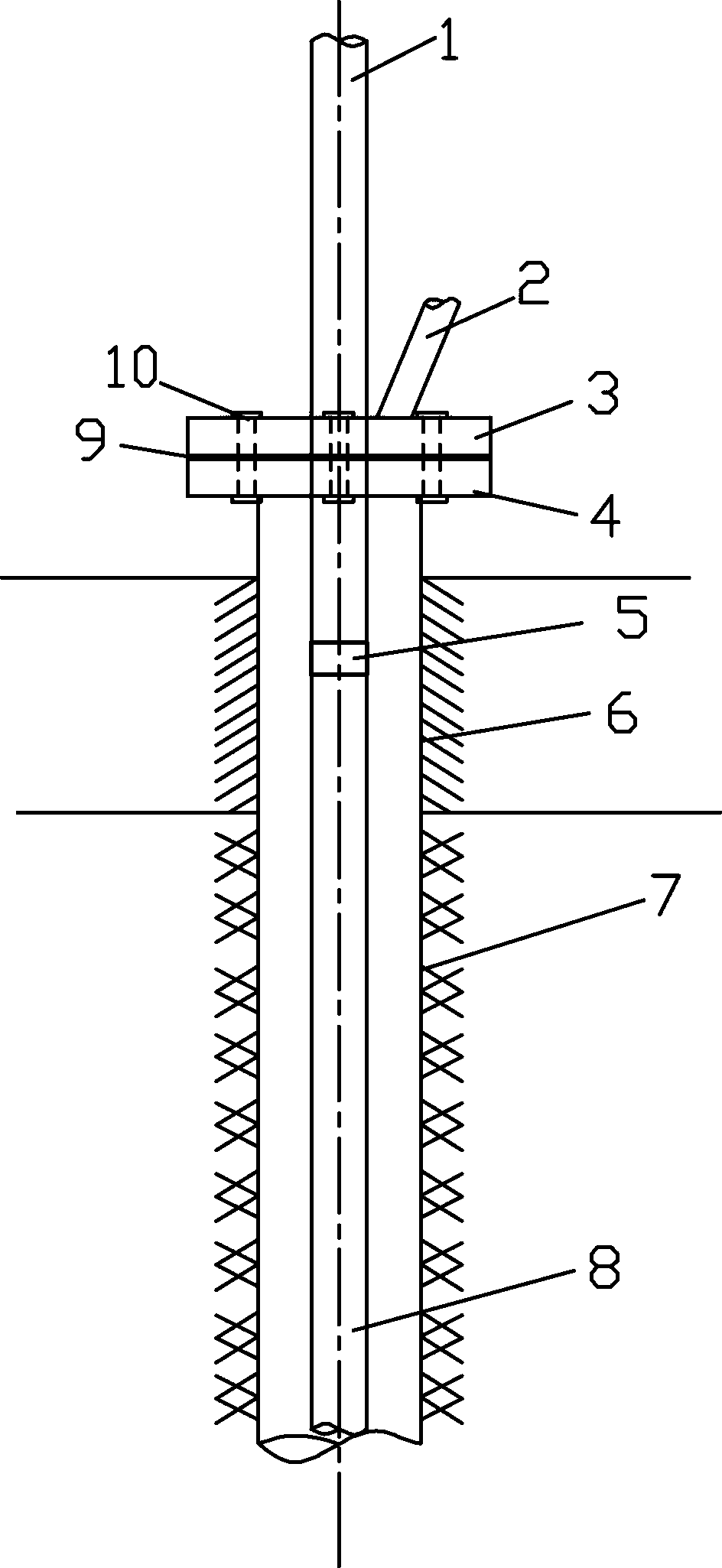

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a quick grouting device, a flange 4 is fixedly installed on the pre-buried orifice pipe 6, the grout inlet pipe 1 passes through the gland plate 3 and is fixedly connected with the gland plate 3, the flange plate 4 and the gland The plates 3 are connected by bolts 10, the grout return pipe 2 is fixedly installed on the gland plate 3, and the polyethylene thin-walled grout pipe 8 communicates with the grout feed pipe 1 through the grout pipe interface snap ring 5;

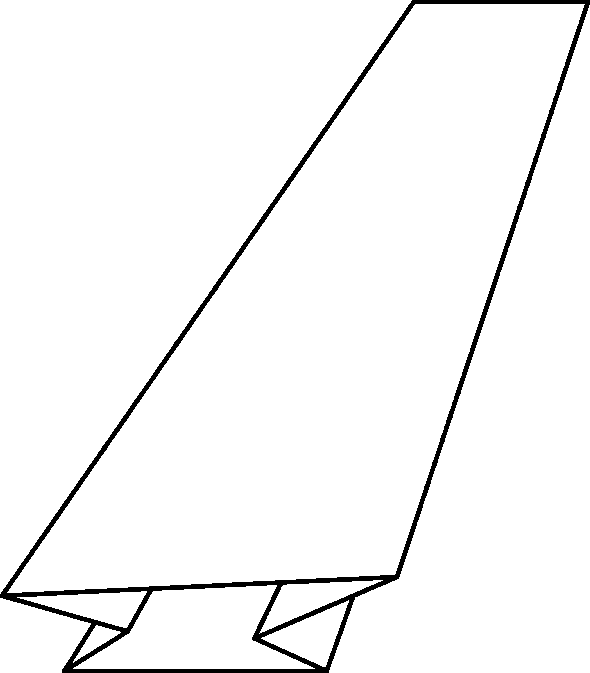

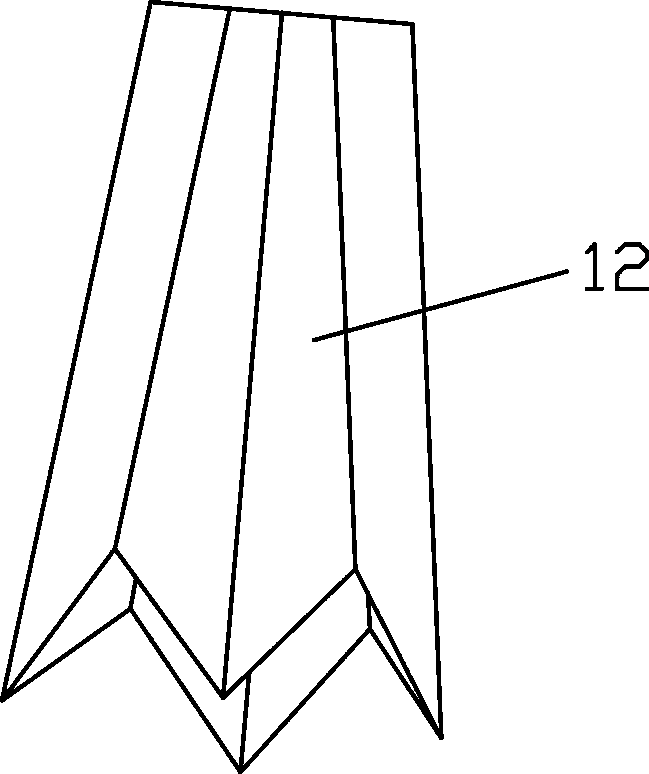

[0034] The polyethylene thin-walled grouting pipe 8 is a strip-shaped pipe body with both sides folded inward symmetrically, and the shape of the slurry outlet 12 of the polyethylene thin-walled grouting pipe 8 is a double "V" shape.

[0035] A rubber pad 9 is provided between the flange plate 4 and the gland plate 3 .

[0036] The polyethylene thin-walled grouting pipe 8 has a wall thickness of 0.5-1 mm and a raised diameter of 3-5 cm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com