A filter press cleaning device

A technology of cleaning device and filter press, which is applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problems such as the decline of filter press effect, achieve the effect of reducing gaps, expanding the beating area, and improving the effect of filter press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

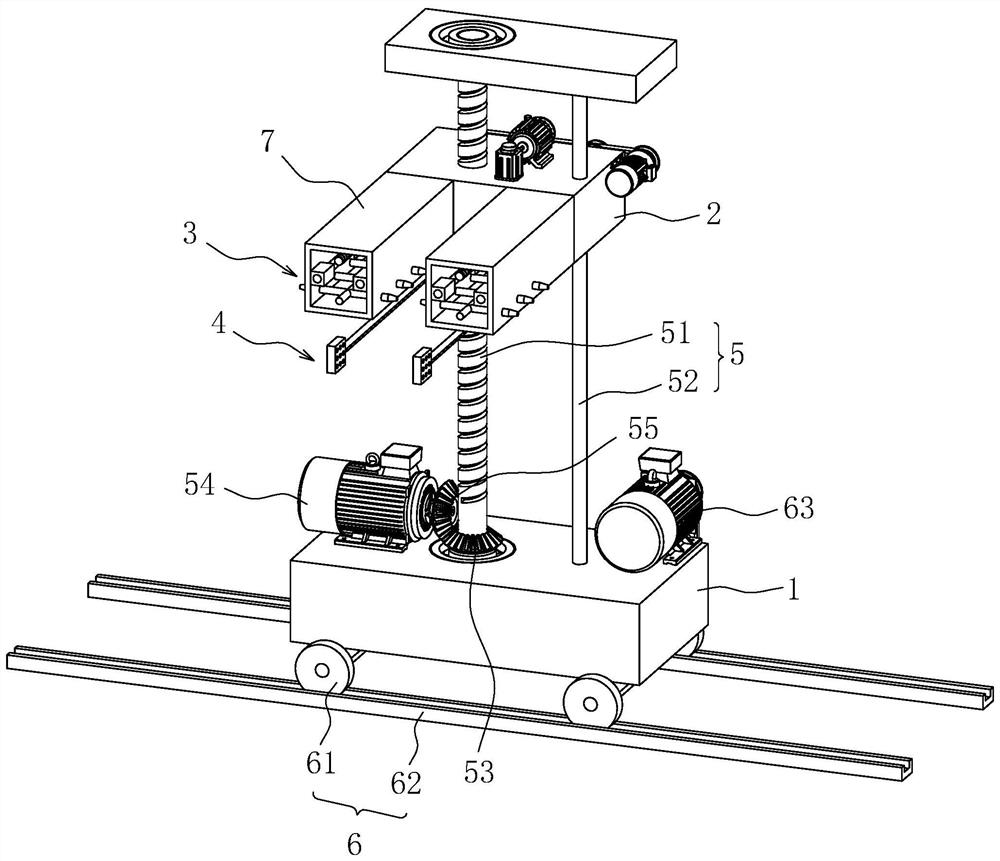

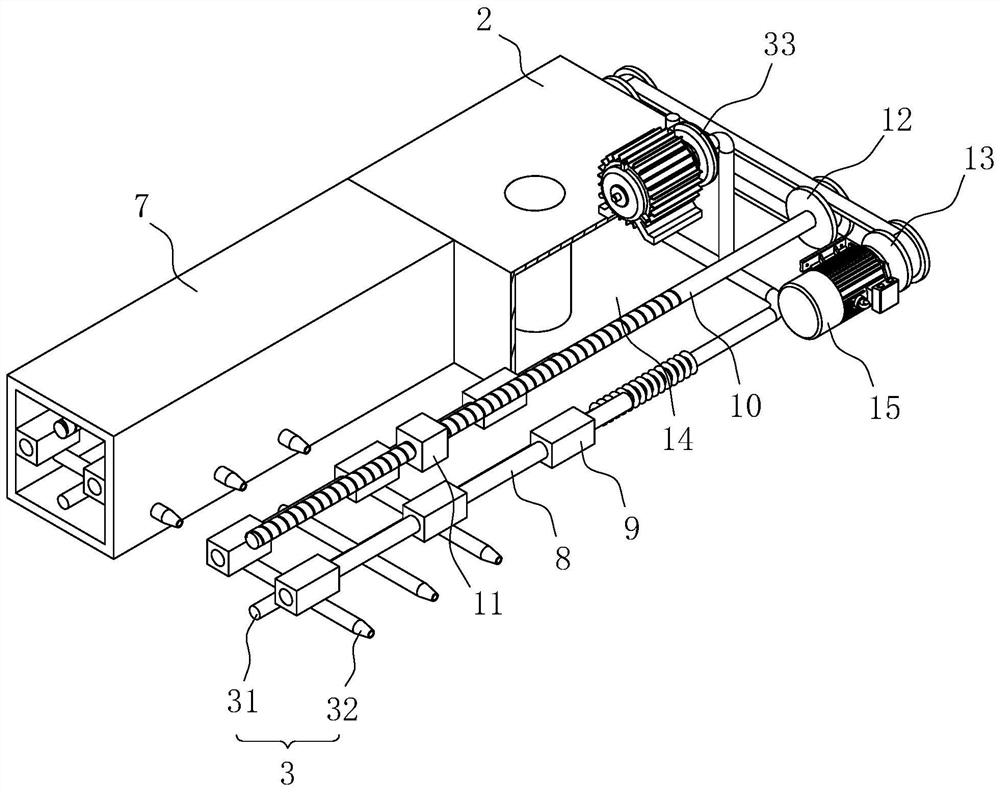

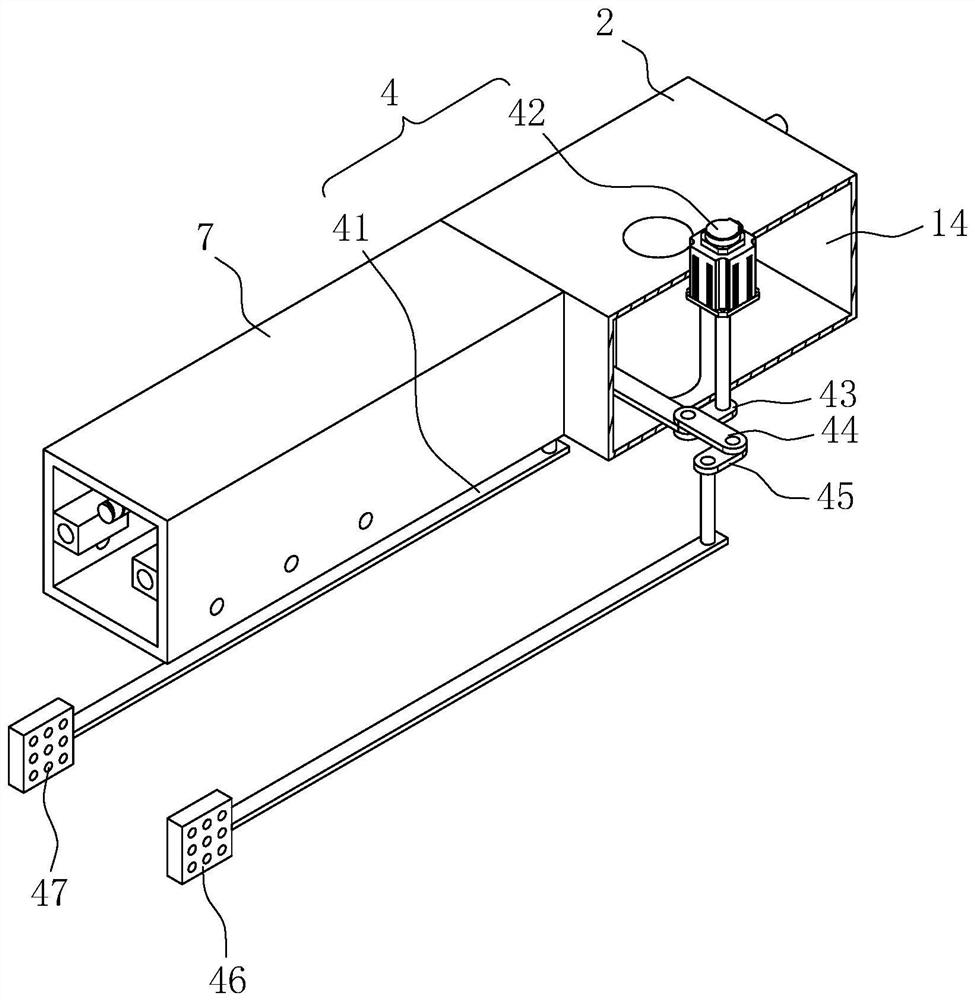

[0037] The following is attached Figure 1-3 The application is described in further detail.

[0038] The embodiment of the present application discloses a filter press cleaning device. refer to figure 1The filter press cleaning device includes a base 1, a mounting base 2 connected to the base 1, a lifting assembly 5 for lifting the mounting base 2 is provided between the base 1 and the mounting base 2, and an installation cavity 14 is provided in the mounting base 2. A flushing assembly 3 is provided in the chamber 14 , a beating assembly 4 for beating the filter plate is provided on the bottom surface of the mounting base 2 , and a driving assembly 6 for driving the base 1 to move is provided on the bottom surface of the base 1 . The flushing assembly 3 flushes the filter plate, the lifting assembly 5 drives the mounting base 2 to move up and down in the vertical direction, and the mounting base 2 drives the flushing assembly 3 and the beating assembly 4 to move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com