Paper pulp dehydration device for decorative base paper production

A technology for decorating base paper and dewatering devices, which is used in pulp dewatering, pulp bleaching, textiles and papermaking, etc., can solve the problems of low dewatering efficiency, single function, and inability to continuously dewater, so as to enhance the dewatering effect, improve functionality, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

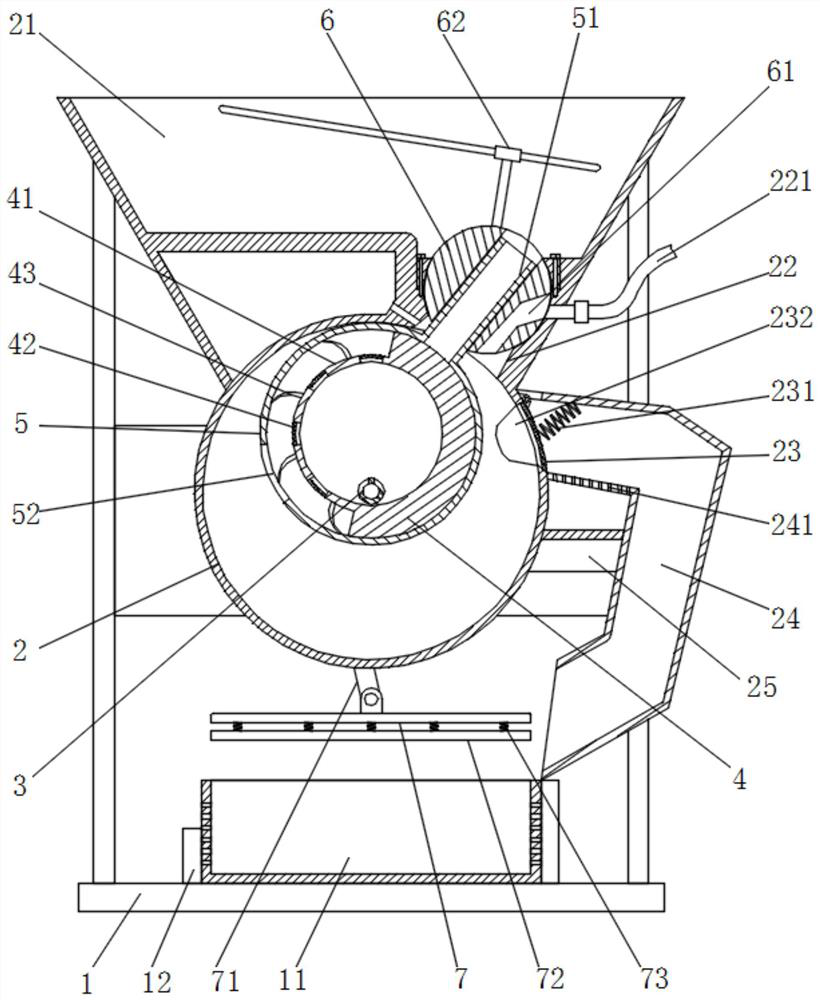

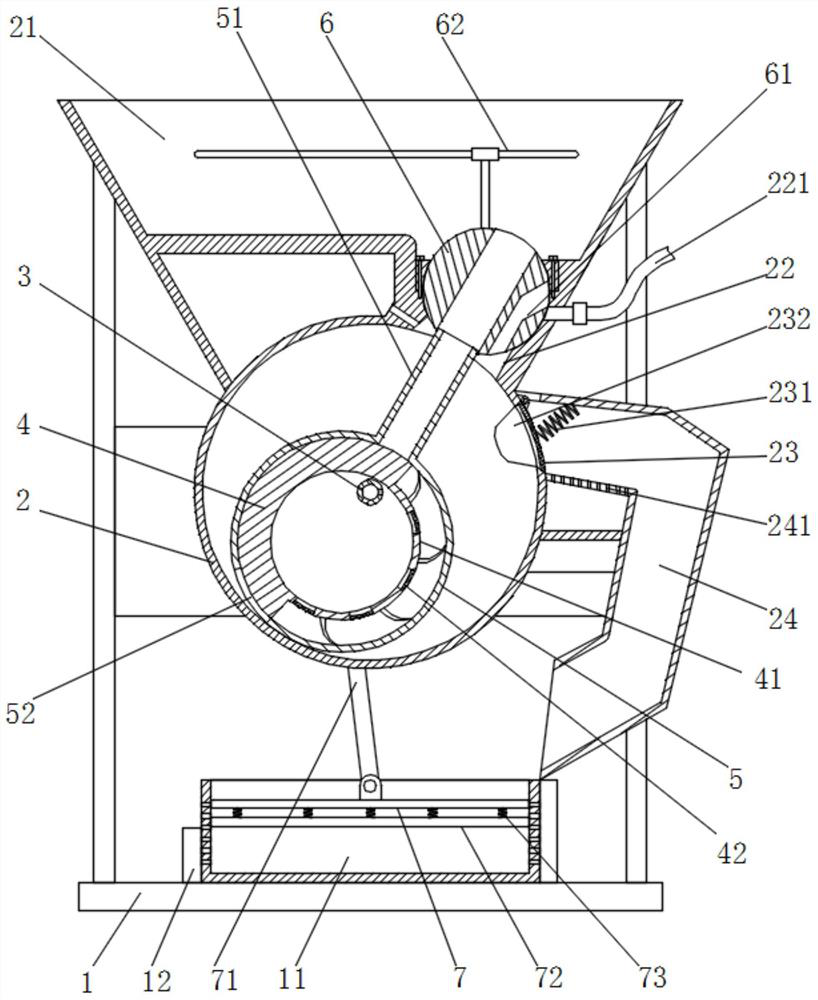

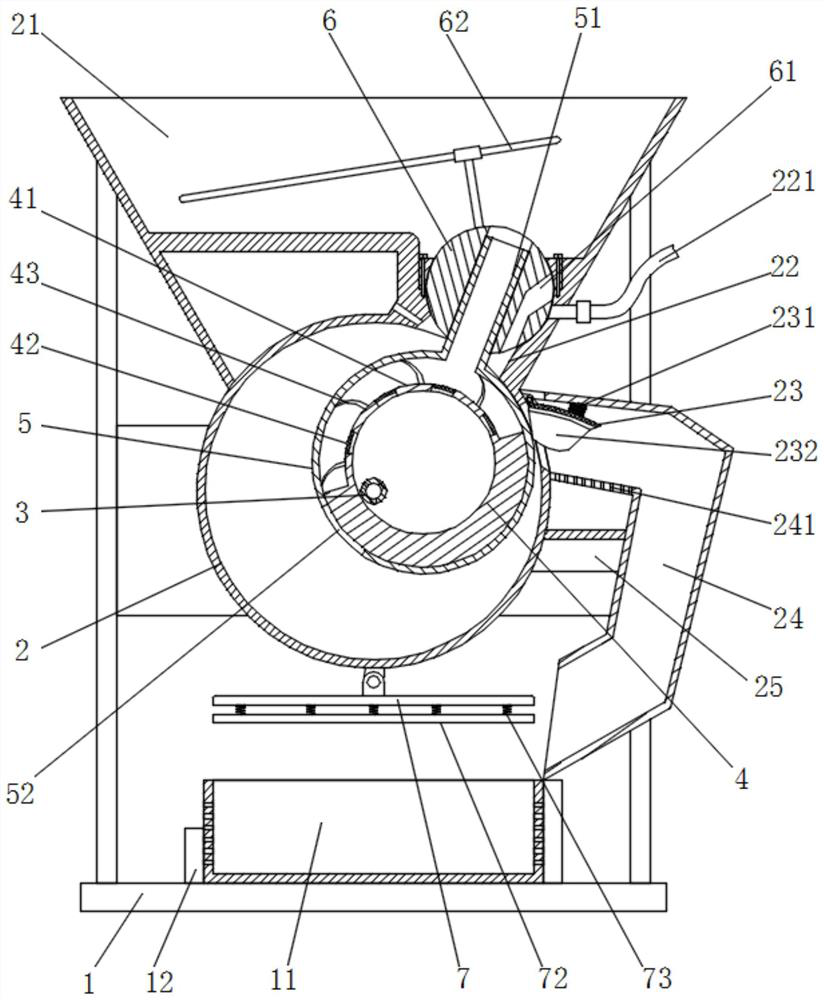

[0024] The present invention provides such Figure 1-5A pulp dewatering device for decorative base paper production as shown, includes a base 1, the top of the base 1 is fixedly installed with a washing and dewatering cylinder 2 through a mounting bracket, and the top of the washing and dehydrating cylinder 2 is fixedly connected with a raw pulp storage tank 21 A connection channel 22 is fixedly installed between the bottom of one end of the raw pulp storage tank 21 and the washing and dehydrating cylinder 2, and the position of the connecting channel 22 near the top of the washing and dehydrating cylinder 2 is provided with air holes, and the washing and dehydrating cylinder 2 The center of the interior is provided with a hollow rotary tube 3, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com