Lining band type filter press with press rolls for fixing mud

A press roll and filter press technology, which is applied in presses, filter separation, and mobile filter element filters, etc., can solve the problems of small gaps in the polyester flat woven filter belt, abnormal operation of the filter press, and slow water filtration, etc. , to achieve the effect of improving the effect of pressing and dehydration, maintaining the best working condition and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

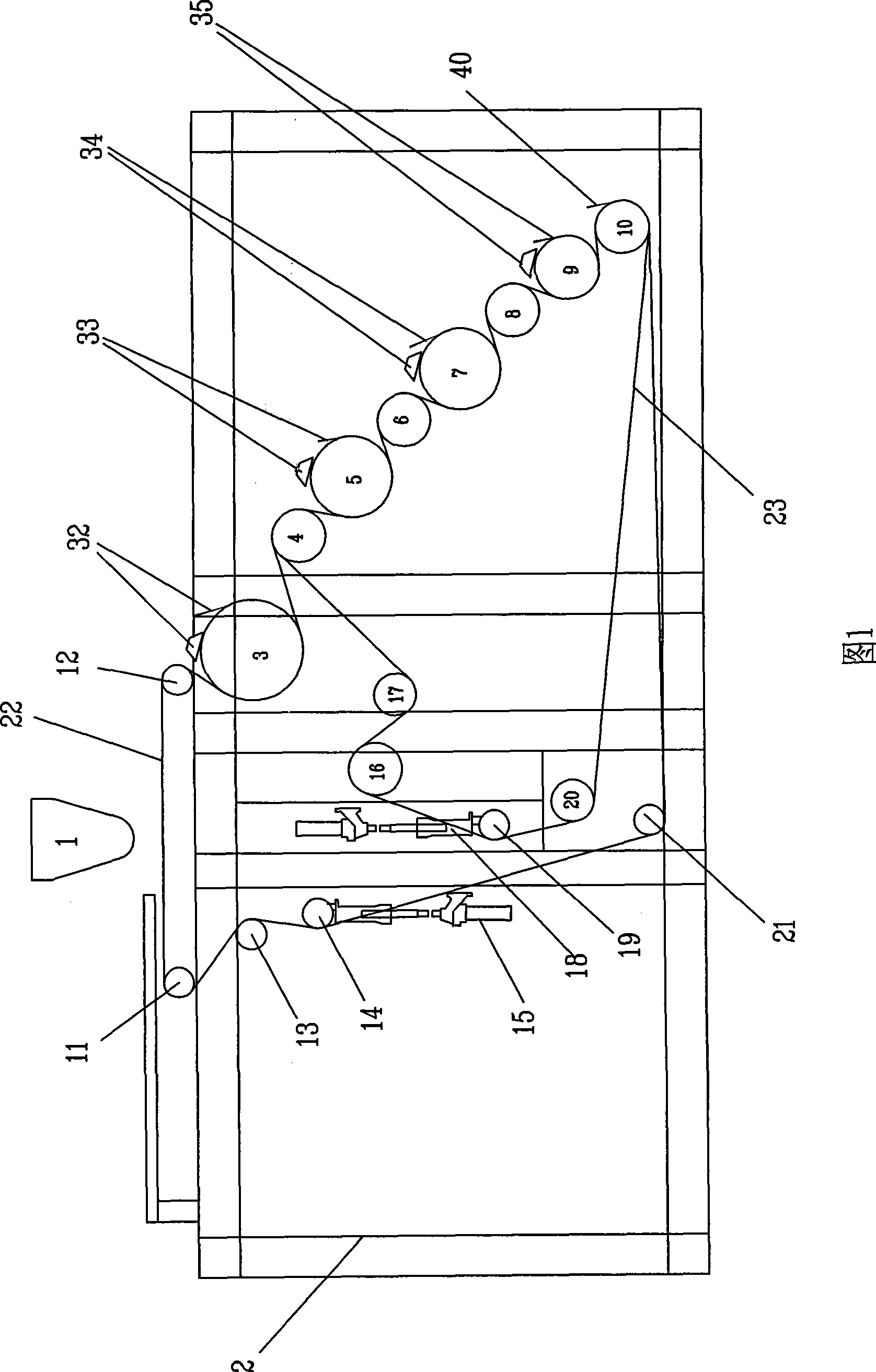

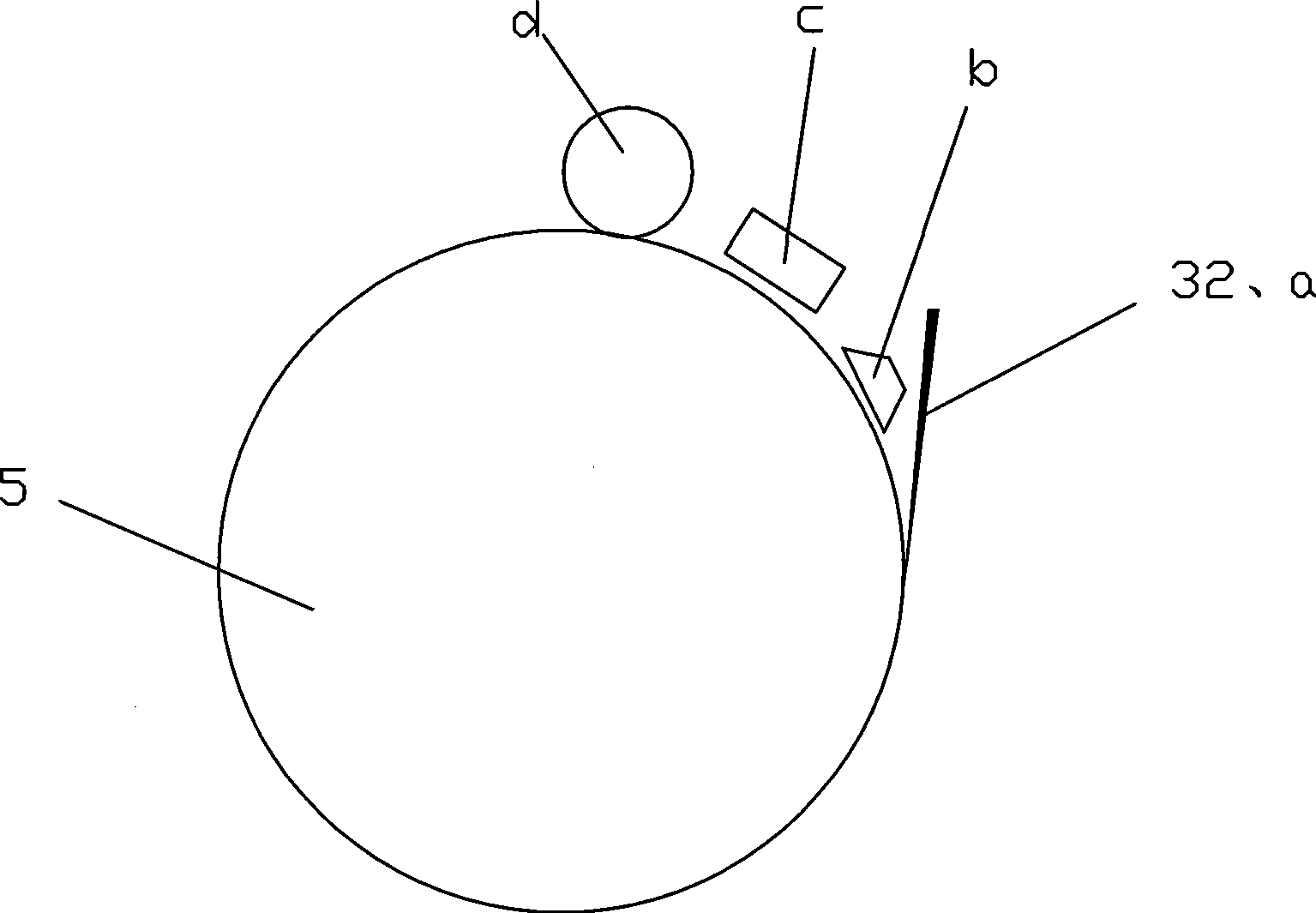

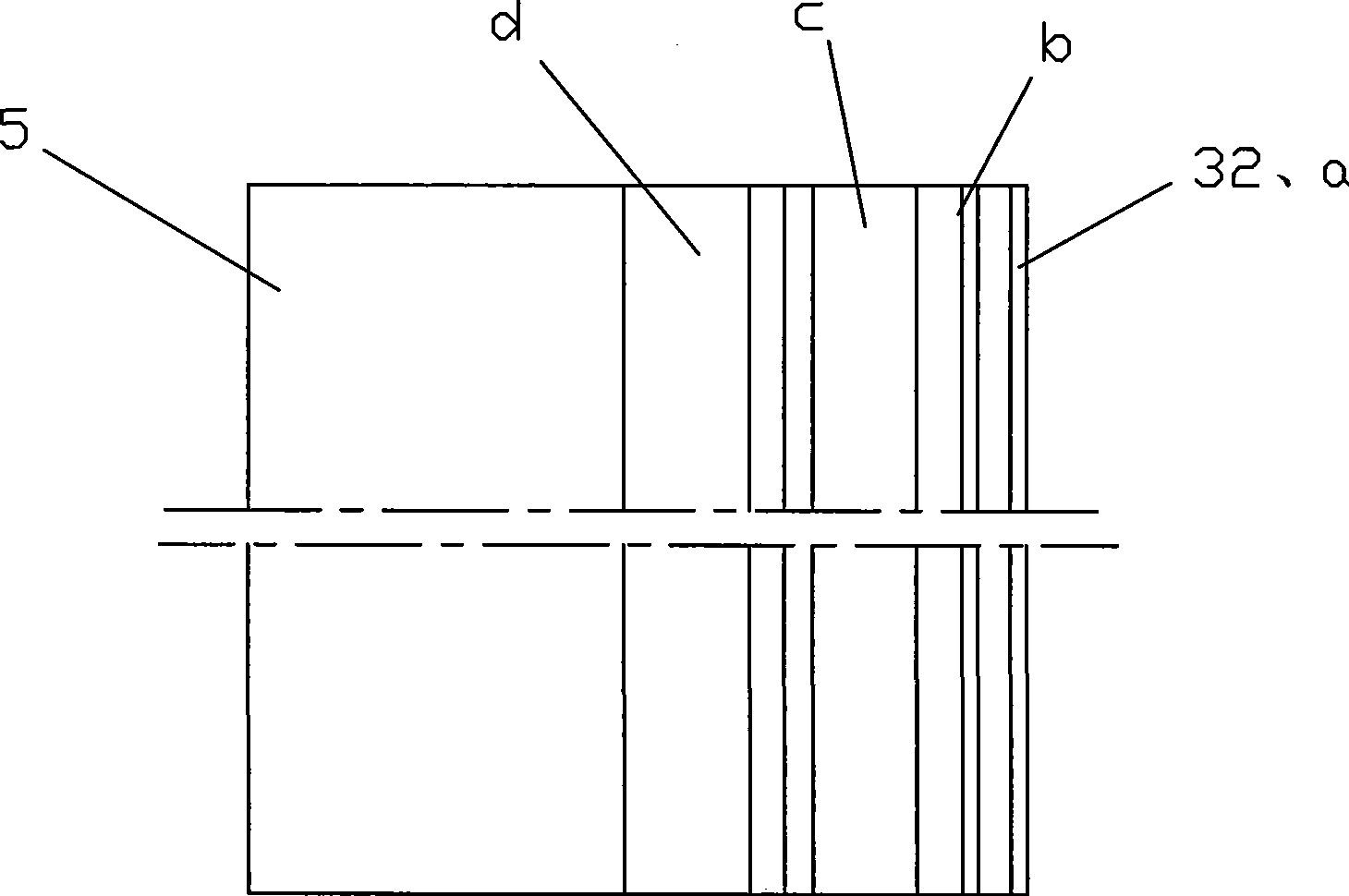

[0018] Referring to Fig. 1, the lined belt filter press with a solid mud press roller includes a frame 2, a driving device, a feeding device, a pressing area and auxiliary devices. Among them, the driving device includes an electric motor, a gearbox and a transmission mechanism. The feeding device includes a conveying mechanism and a hopper 1, and the hopper 1 is installed above the filter belt 22. The press area includes 1#, 2#, 3#, 4# solid mud squeeze rollers 3, 5, 7, 9, 1#~7# rollers 4, 6, 8, 10, 13, 16, 17, 1#~ 3# Guide rollers 12, 20, 21 and pressurized lining belt 23; the solid mud press roll is a press roll with a solid mud layer wrapped on the surface of the roller. The solid mud layer is made of high elasticity, high recovery, high friction coefficient, and convenient and dewatering The material for material separation, the solid mud layer material can be a kind of in wool fiber filter belt, rubber belt with holes, sponge, and the present embodiment solid mud pressi...

Embodiment 2

[0022] The pressing area of this embodiment is different from the integrated structure of the pressing area in Example 1, and adopts a segmented pressing area. The pressing area is divided into front and rear pressing areas. The front and rear pressing areas are equipped with independent front and rear filters bring. According to the requirements of the use, the pressurized backing belt can be superimposed under the filter belt in the front section of the press zone, or the pressurized backing belt can not be superimposed. In this embodiment, the pressurized backing belt is not used in the front section of the press section, and the filter belt 60 can be a traditional polyester filter belt. , such as polyester plain woven filter belt, can also be made of the same material as the solid mud layer of the solid mud press roll, and has a fiber-planted wool filter belt with a solid mud effect, and can be obtained by cooperating with the solid mud press roll Better solidification e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com