Three-chamber structure small-test filter-press analog device

A simulation device and pressure testing technology, which is applied in the fields of dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inconvenient operation, high cost, and low efficiency, and achieve Improved filter press effect, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

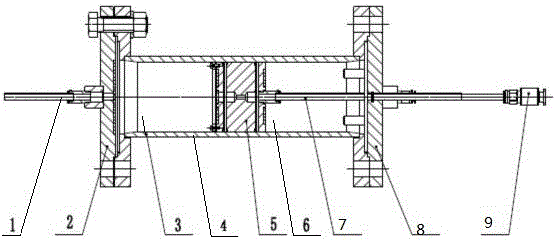

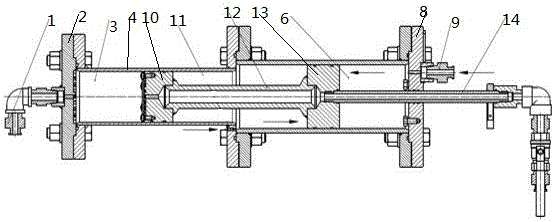

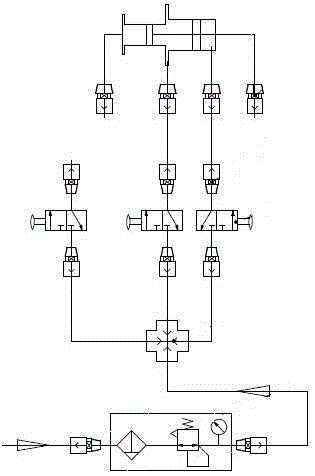

[0020] like figure 2 As shown, a three-chamber small test filter press simulation device includes a detachable sealed casing 4 at both ends (the two ends of the casing 4 are the front end cover 2 and the rear end cover 8 respectively), and the casing 4 is covered by the first piston. 10 and the second piston 13 are divided into a working chamber 3, an intermediate chamber 11 and a pressurized chamber 6 which are arranged in a straight line, filter cloths are arranged on the side walls of both ends of the working chamber 3, and the two ends of the working chamber 3 are respectively It communicates with the drain channel on the outer drain pipe 1 and the first piston 10, the first piston 10 and the second piston 13 are connected by a rigid first inner drain pipe 12, and the first inner drain pipe 12 is connected with the first piston 10 and the first pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com