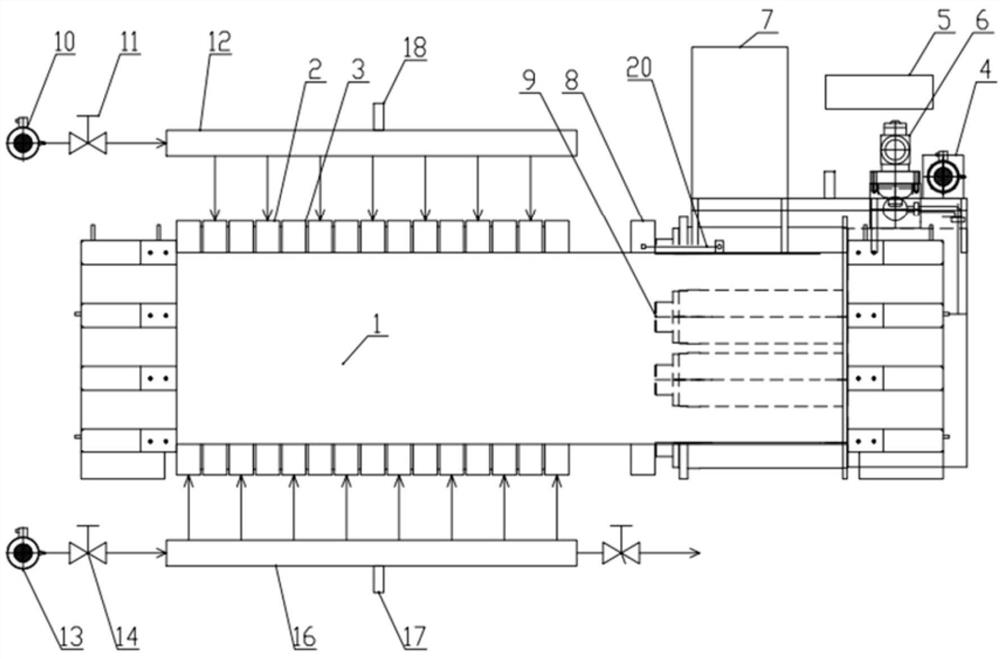

High-pressure filter press based on oil cylinder displacement control

A filter press, high pressure technology, applied in the field of high pressure filter press, can solve the problems of water and oil contact pollution, high failure rate, fracturing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

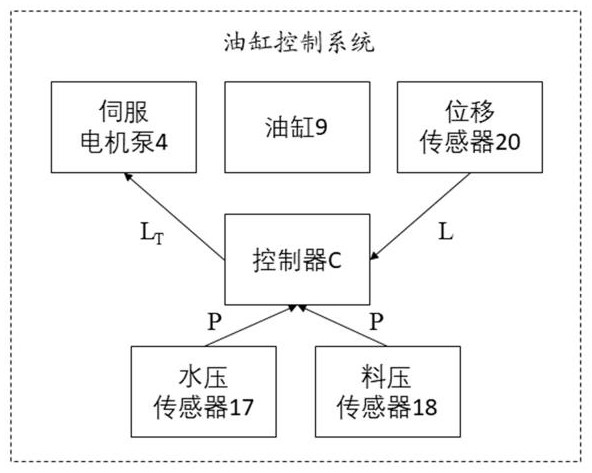

[0053] In a first embodiment, the controller C is configured to perform the following functions:

[0054] 1) Receive the current pressure value P from the water pressure sensor 17 or the material pressure sensor 18, which is the feed pressure in the first stage of dehydration, and the inlet water pressure in the second stage of dehydration;

[0055] 2) Based on the current pressure value P, determine the target displacement value L according to the corresponding relationship stored in the controller C T ;

[0056] 3) Based on the target displacement value L T , send a control signal to control the servo motor pump 4 to work, so that the displacement L of the oil cylinder 9 increases;

[0057] 4) When the current displacement L of the cylinder 9 reaches the target displacement value L T Afterwards, the work of controlling the servo motor pump 4 is stopped.

[0058] In the present invention, the pressure value P and the target displacement value L are determined through pre-...

no. 2 example

[0063] Based on the above relationship (1), the following relationship can be further obtained:

[0064] ΔL T =kΔP (2)

[0065] Among them, ΔP is the difference between the pressure values P of the pressure fluid at two adjacent measurement moments, that is, the pressure change value; ΔL T is the target displacement value L of the oil cylinder corresponding to two adjacent measurement moments T The difference is the displacement change value.

[0066] Based on the above relationship (2), in the second embodiment, the controller C is configured to perform the following functions:

[0067] 1) Receive the current pressure value P from the water pressure sensor 17 or material pressure sensor 18;

[0068] 2) Based on the current pressure value P, determine its pressure change value ΔP relative to the pressure value at the previous measurement moment;

[0069] 3) Based on the pressure change value ΔP, and ΔP and ΔL T The corresponding relationship between, such as the a...

no. 3 example

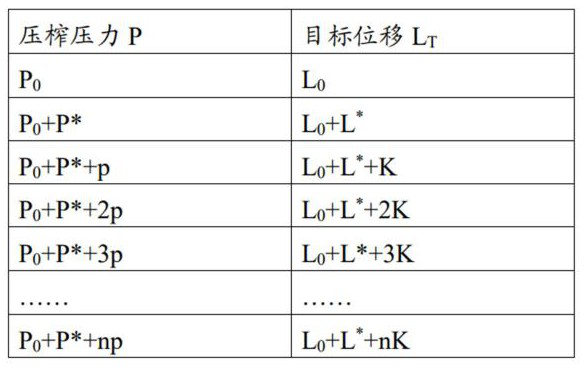

[0072] Based on the above relationship (2), if ΔP is taken as a fixed value p, for example, it can be 0.5 Mpa, since k and p are both fixed values, ΔL T is also a fixed value, denoted as K, and the following relationship can be further obtained at this time:

[0073] K = k·p (3)

[0074] Based on the above relationship (3), in the third embodiment, the controller C is configured to perform the following functions:

[0075] 1) Receive the current pressure value P from the water pressure sensor 17 or material pressure sensor 18;

[0076] 2) Monitor the change of the pressure value P. Whenever the pressure value P increases by a constant pressure increment p, a control signal is sent to control the operation of the servo motor pump 4, so that the displacement of the oil cylinder 9 increases by a corresponding constant displacement increment K .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com