Movable check valve of filter press

A filter press, mobile technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve problems such as increasing operating and management costs, easily blocking filter holes of filter plates, and affecting filter press efficiency. , to achieve the effect of simple structure, easy installation, maintenance and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

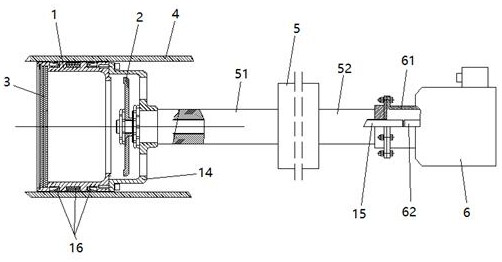

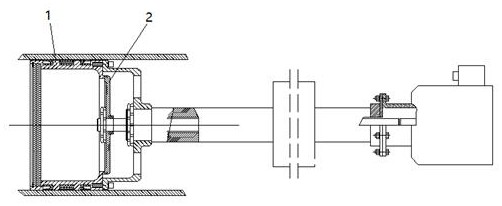

[0029] See Figure 1-6 , A filter machine is moved, including a valve body 1 and a spool 2, and the valve body 1 is a cylindrical structure and slides to be mounted inside the filter cylinder 4, and the valve body 1 is propelled. The device 5 drives it before and after the inner wall of the filter cylinder 4, and the front end of the valve body 1 is mounted with detachable filter plate 3, and the spool 2 is driven by the valve core driver 6 to move forward, turned on or off the valve body 1. Internal flow path.

[0030] It should be noted that the outer diameter of the valve body 1 in the present embodiment is slightly smaller than the inner diameter of the filter cylinder 4, and the inner diameter of the valve body 1 is smaller than the inner diameter of the front port, thereby at the rear port of the valve body 1. The valve seat stop structure is formed; the spool 2 is located behind the rear port of the valve body 1, and the spool 2 moves forward or backward on the drive of the ...

Embodiment 2

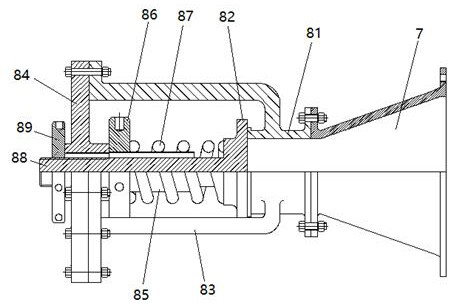

[0053] See Figure 7 , 8 In this embodiment, the valve body 1 is a cylindrical structure, and the push rod connecting bracket 14 is also a cylindrical structure, and the outer diameter of the valve body 1 and the push rod connecting bracket 14 is slightly smaller than the inner diameter of the filter cylinder 4, and The inner diameter of the front port of the rod connection bracket 14 is smaller than the inner diameter of the port after the valve body 1, thereby forming a valve seat stop structure at the front port of the push rod connection bracket 14; in addition, the rear end of the push rod connecting bracket 14 is a hollow structure. .

[0054] The spool 2 is located inside the valve body 1, and the spool 2 moves forward or rearward in the drive of the spool driver 6. When moving backward, the spool 2 is pressed in the front port of the propeller connection bracket 14. The end face (the valve seat stop is at the interior flow channel of the shut-off valve body 1; when moving f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com