Sewage treatment method

A sewage treatment and sewage technology, applied in water/sewage treatment, neutralized water/sewage treatment, reductive water/sewage treatment, etc., can solve the problem of electrode life not exceeding 2 years, low market acceptance, not exceeding 50%, etc. to improve the biodegradability, increase the degree of mineralization, and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

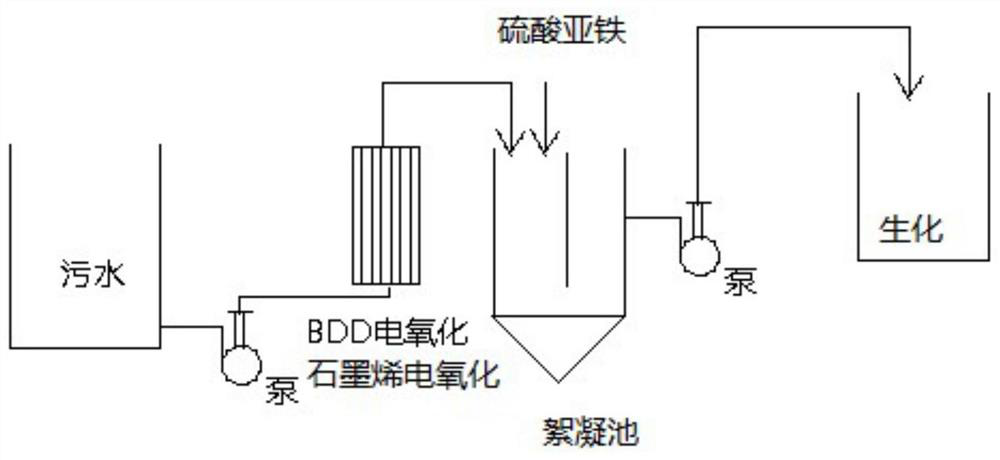

[0021] Step 1. Use BDD electrodes to pretreat sewage, and the current density of BDD electrodes is 500A / square meter;

[0022] Step 2. Add ferrous sulfate as a flocculant with an addition amount of 0.2g / ton of water into the flocculation tank. When adding ferrous sulfate, add a small amount of alkali to adjust the pH to a suitable pH for the subsequent biochemical process. The sewage is pretreated Then flow into the flocculation tank and carry out flocculation treatment;

[0023] Step 3. The sewage is treated by biochemical process.

Embodiment 2

[0025] In embodiment 2, step 1 is adjusted, and the BDD electrode is adjusted to a graphene electrode, and the others are consistent with embodiment 1.

Embodiment 3

[0027] Embodiment 3 is adjusted for step 2, and the add-on of ferrous sulfate is adjusted to 0.5g / ton of water, and others are all consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com