Patents

Literature

124 results about "Tripolyphosphatase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preventing off-flavor development and preserving seasoning flavor in irradiated meat and meat products

InactiveUS6099879ASlow onsetReduce developmentMilk preparationDough treatmentAdditive ingredientFood flavor

A method comprising the step of treating meat and meat products, including fish, poultry, fish products, and poultry products, with a stabilizing amount of rosemary extract or rosemary extract in combination singly or collectively with tocopherols, ascorbic acid, citric acid, or sodium tripolyphosphate, prior to exposure of the meat or meat products to ionizing radiation, enhances the flavor and shelf life thereof. In addition, the active antioxidant ingredients of rosemary extract may be used individually or collectively as a replacement for rosemary extract, these being carnosic acid, carnosol, and rosmarinic acid, which have been found equivalent to or superior to rosemary extract itself for purposes of the present invention when used in the concentrations set forth herein.

Owner:KALAMAZOO HLDG INC

Taiwan-style beef sausage and preparation method thereof

The invention relates to a sausage, in particular to a Taiwan-style beef sausage and preparation method thereof. The Taiwan-style beef sausage is prepared from the following raw materials in parts by weight: 40 to 55 parts of beef, 1 to 4 parts of beef tallow, 5 to 17 parts of protein meat, 10 to 25 parts of duck neck skin, 12 to 25 parts of ice water, 0.5 to 2 parts of salt, 0.1 to 0.4 part of tripolyphosphate, 0.001 to 0.015 part of monascus color, 0.1 to 0.2 part of iso-VC sodium, 0.001 to 0.015 part of sodium nitrite, 0.1 to 0.2 part of aminotransferase, 2 to 5 parts of rehydration histone, 5 to 9 parts of white sugar, 0.1 to 0.3 part of white spirit, 7 to 15 parts of cassava starch, 0.5 to 0.7 part of carrageenan, 1 to 2.5 parts of R-type protein, 1 to 2.5 parts of isolated soybean protein, 0.1 to 0.15 part of essential oil, 0.3 to 1 part of ox bone essence, 0.1 to 0.3 part of aroma enhancing juice, 0.1 to 0.3 part of yeast cream, 0.2 to 0.5 part of monosodium glutamate, 0.1 to 0.2 part of white pepper powder, 0.01 to 0.03 part of netmeg powder, 0.02 to 0.07 part of licorice powder, 0.1 to 0.3 part of cassia oil powder, 0.01 to 0.02 part of garlic powder, and 0.015 to 0.03 part of ginger powder; the light sausage product is prepared from the raw materials by weight by the unfreezing of raw meat, trimming, mincing, primary stirring, salting, secondary stirring and filling, cooking in a smoking oven, cooling, shearing and pacing; and the Taiwan-style beef sausage has the advantages of good mouthfeel, full meat granules and low fat, and is health-care food.

Owner:濮阳东大食品有限公司

Tripolyphosphate pet food palatability enhancers

ActiveUS20050106285A1Improve palatabilityLow costConfectioneryAnimal housingAdditive ingredientVegetable Proteins

A palatability enhancing composition for extruded pet food containing at least one tripolyphosphate salt in an amount effective to enhance palatability and at least one ingredient selected from meat products, meat by-products, fish products, fish by-products, dairy products, dairy by-products, sources of microbial proteins, vegetable proteins, carbohydrates and amino acids. Methods for enhancing pet food palatability with the disclosed palatability enhancing compositions and extruded pet food compositions coated therewith are also disclosed.

Owner:APPLIED FOOD BIOTECH

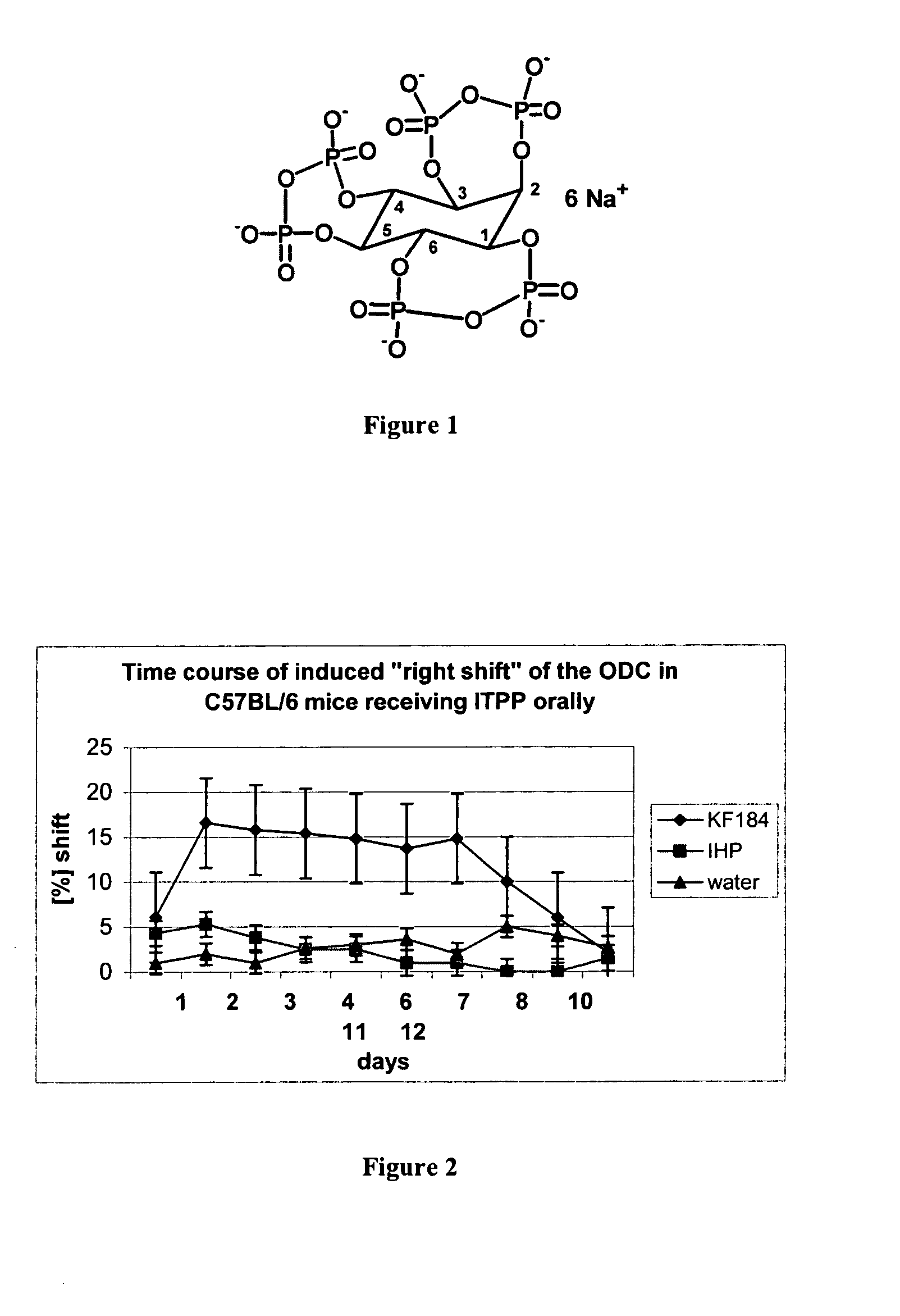

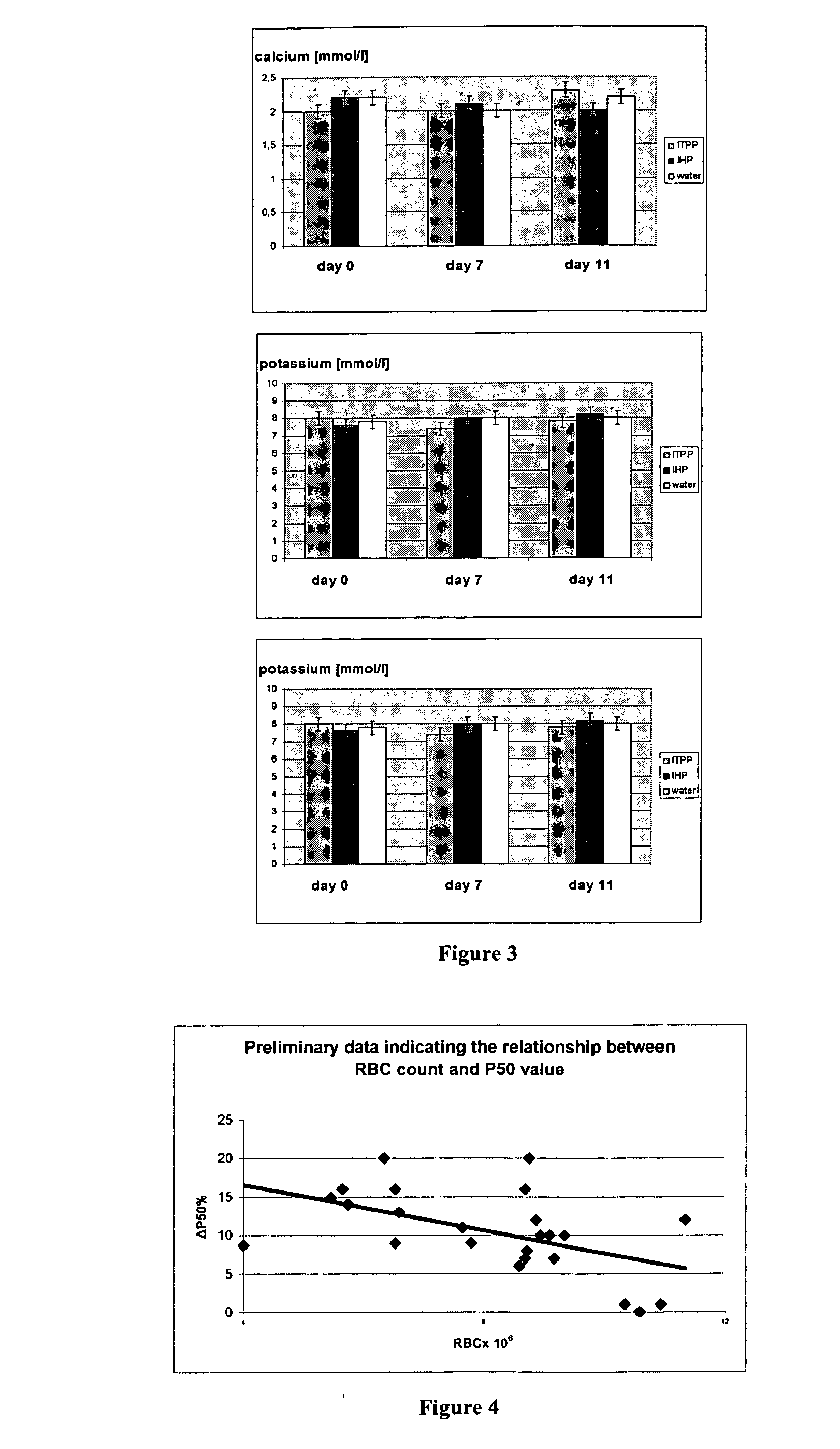

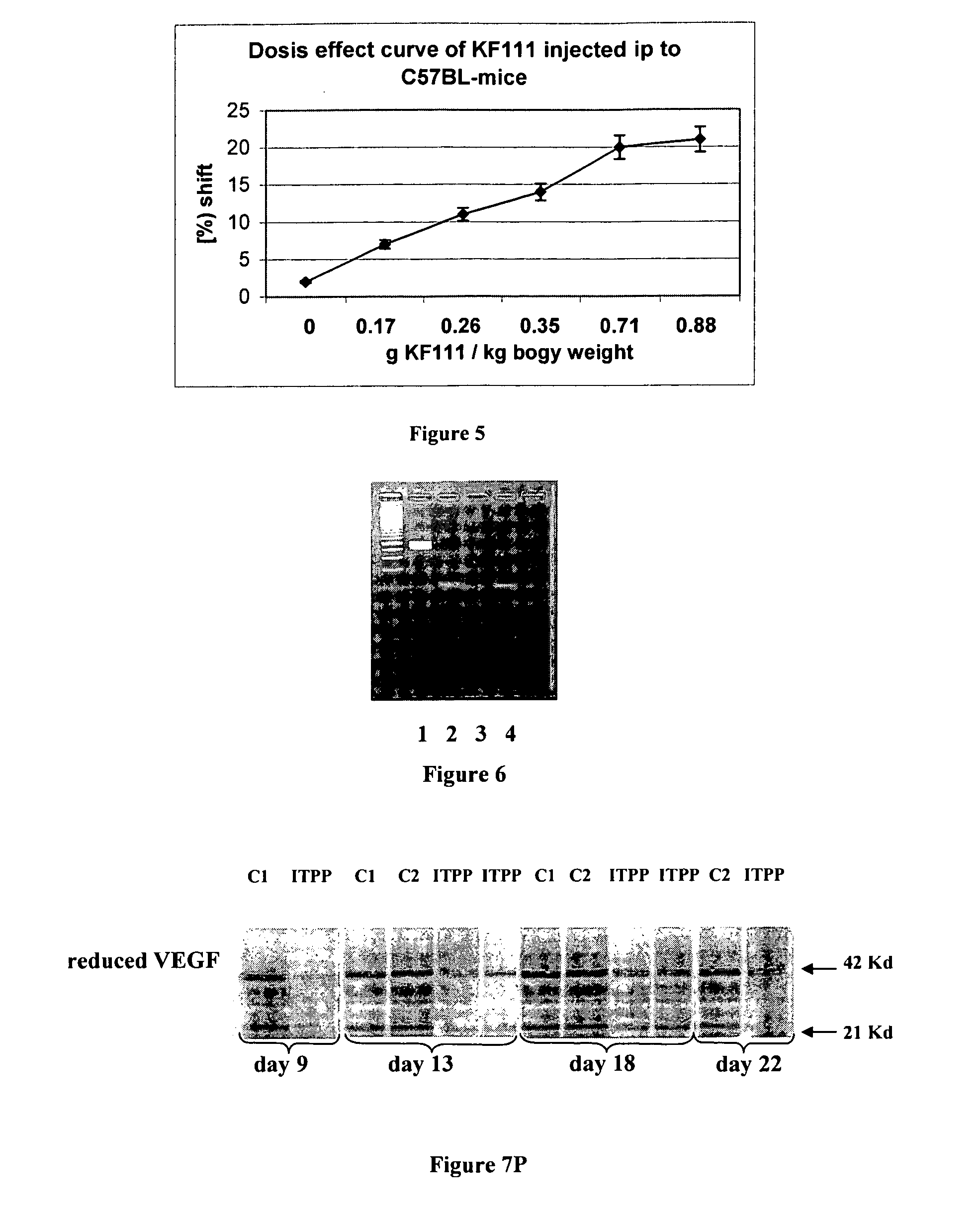

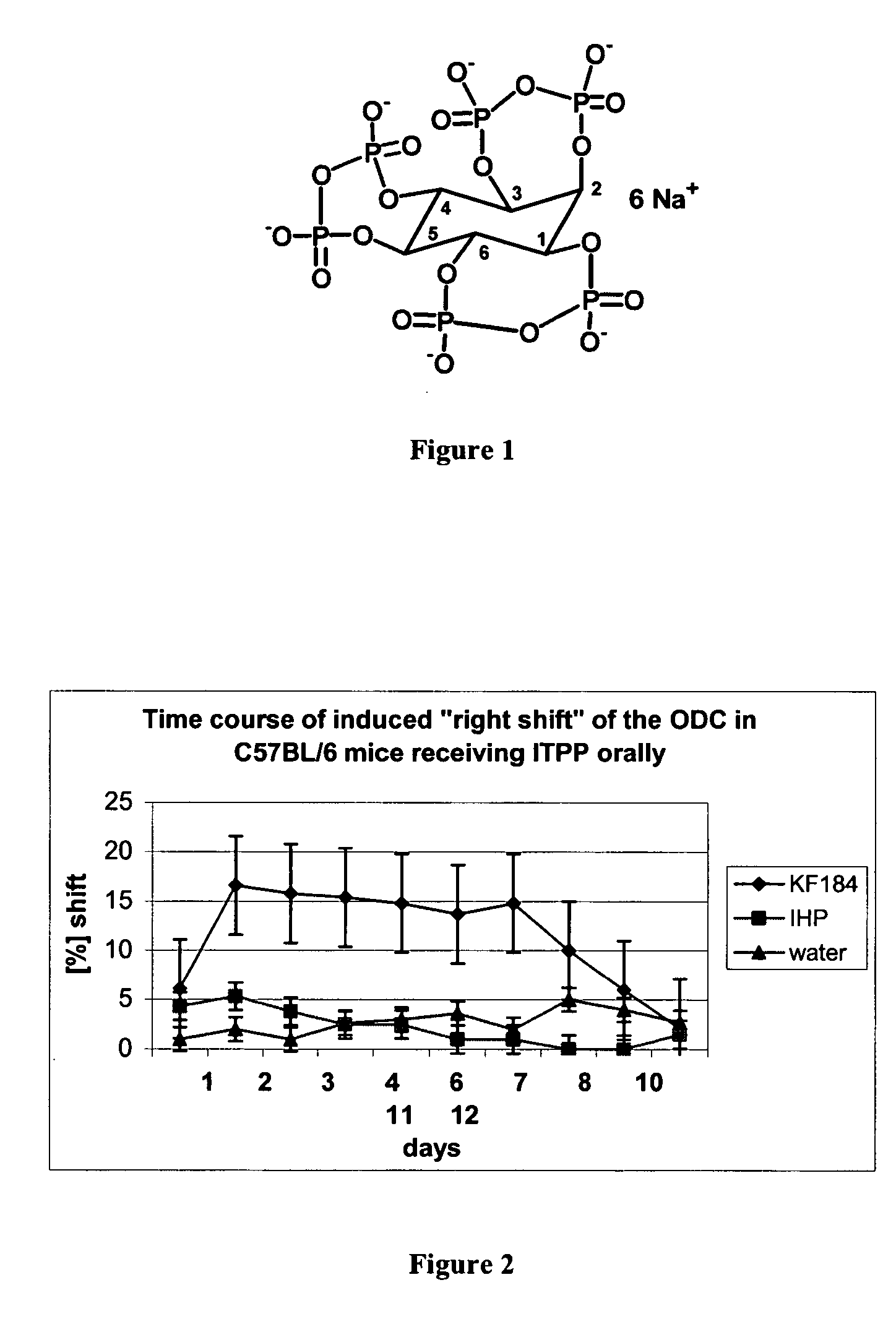

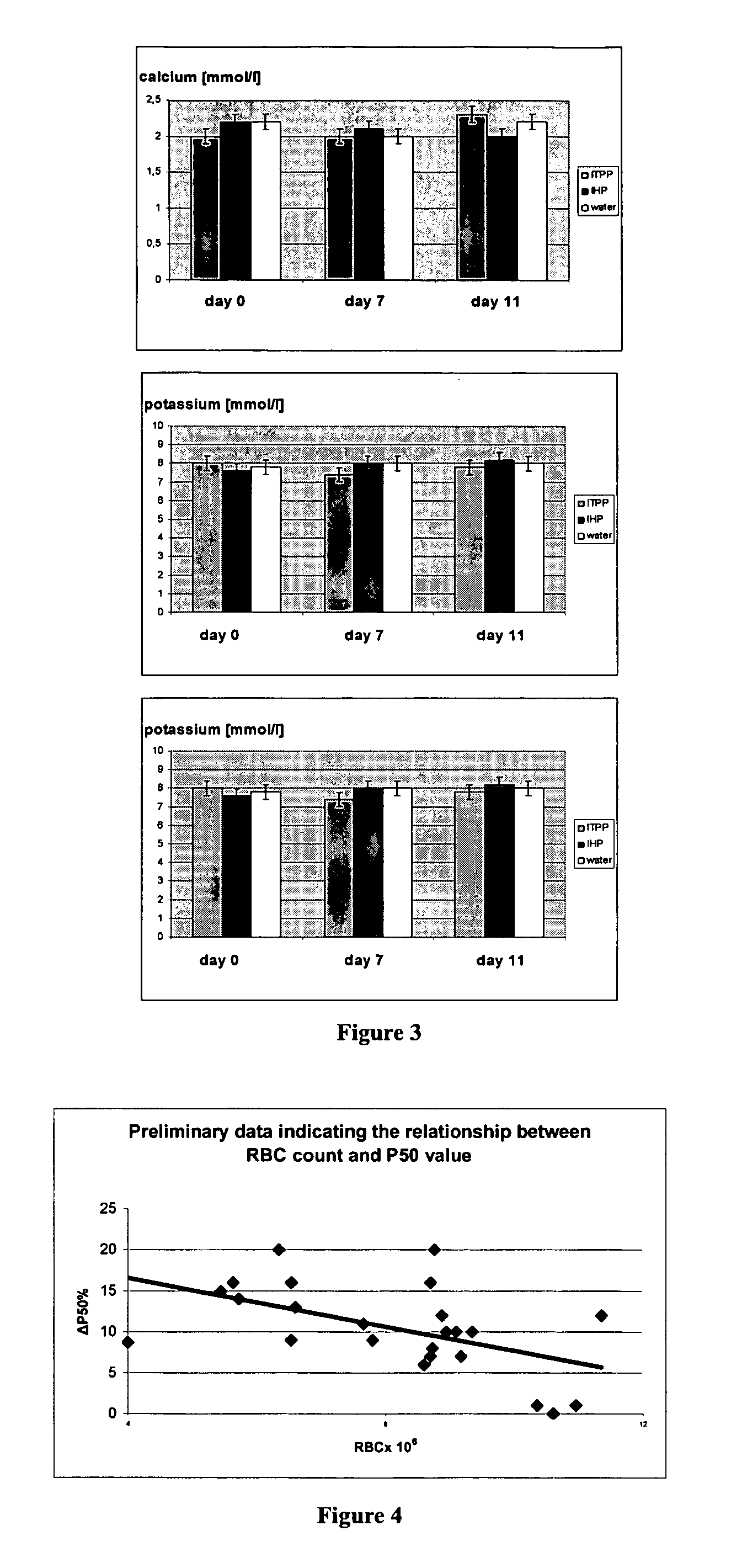

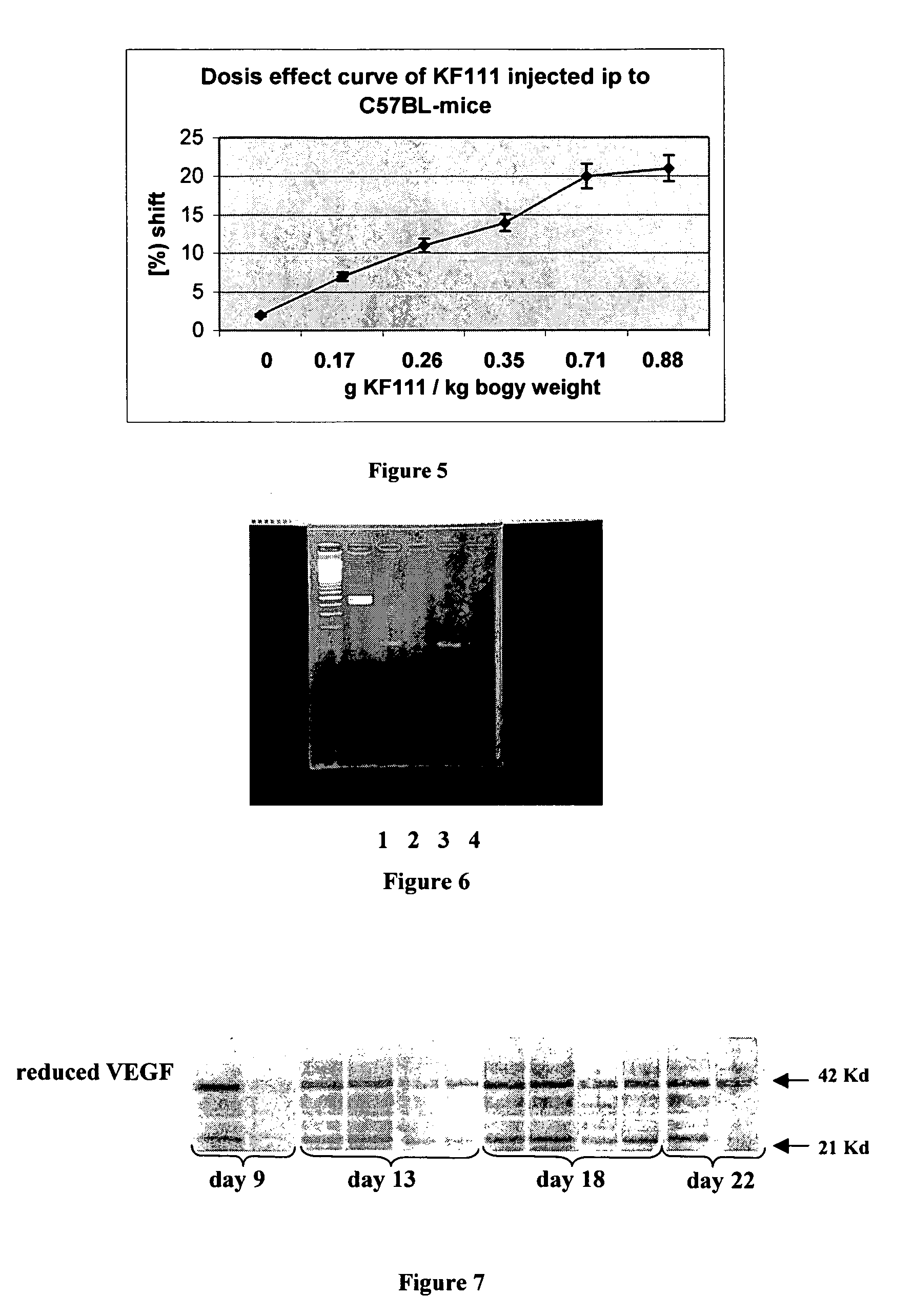

Use of inositol-tripyrophosphate in treating tumors and diseases

InactiveUS20060258626A1Increasing regulated delivery of oxygenLowering affinity for oxygenBiocideCosmetic preparationsAbnormal tissue growthRadiation sensitivity

Inositol-tripyrophosphate is an allosteric effector of hemoglobin due to its ability to cross the plasma membrane of red blood cells and deliver oxygen to solid tumors, by lowering the oxygen affinity of the hemoglobin of red blood cells. The present invention is directed to the use of inositol-tripyrophosphate to reduce hemoglobin's affinity for oxygen in circulating red blood cells. The present invention is further directed to the use of inositol-tripyrophosphate to inhibit angiogenesis and enhance radiation sensitivity of hypoxic tumors. The present invention is further directed to the use of inositol-tripyrophosphate for the treatment of various types of cancers, Alzheimer's disease, stroke and osteoporosis.

Owner:NORMOXYS

Composition for stimulating bone-formation and bone consolidation

InactiveUS20060018973A1Stimulate bone-formationBiocideOrganic active ingredientsMedicineWater soluble

The present invention relates to a composition for stimulating bone-formation and bone-consolidation, more particularly, to a composition for stimulating bone-formation and bone-consolidation by adding a material for stimulating bone-forming and bone-consolidation to the mixture of tripolyphosphate and water-soluble chitosan. The composition of the present invention can stimulate bone-formation and bone-consolidation in early stages.

Owner:REGEN BIOTECH INC

Tripolyphosphate pet food palatability enhancers

InactiveUS7244460B2Improve palatabilityHigh nutritional valueConfectionerySweetmeatsAdditive ingredientVegetable Proteins

A palatability enhancing composition for extruded pet food containing at least one tripolyphosphate salt in an amount effective to enhance palatability and at least one ingredient selected from meat products, meat by-products, fish products, fish by-products, dairy products, dairy by-products, sources of microbial proteins, vegetable proteins, carbohydrates and amino acids. Methods for enhancing pet food palatability with the disclosed palatability enhancing compositions and extruded pet food compositions coated therewith are also disclosed.

Owner:APPLIED FOOD BIOTECH

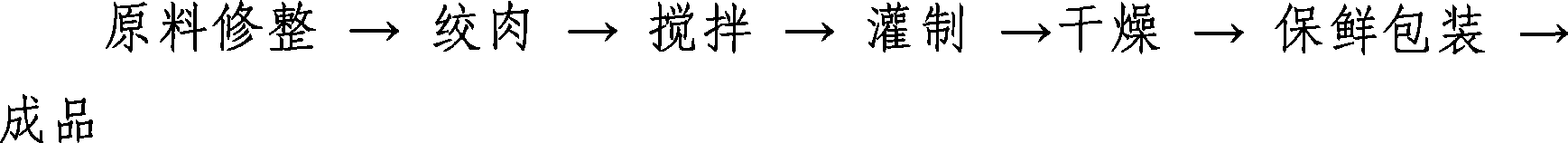

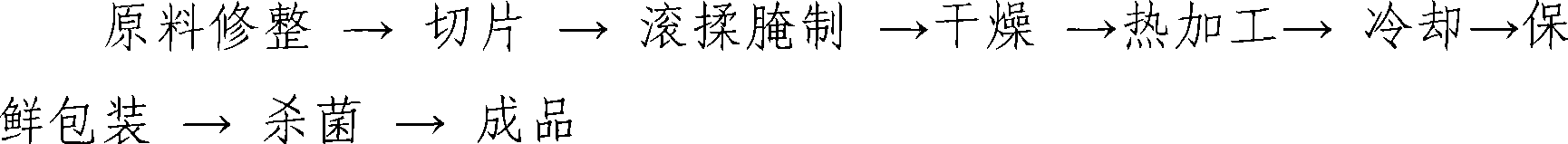

Mutton sausage and preparation method thereof

The invention provides a mutton sausage and a preparation method thereof. The mutton sausage comprises raw materials and supplementary materials. The raw materials comprise the following components in portion by weight: 70 to 80 portions of lean mutton, 10 to 20 portions of vegetable oil, and 2 to 10 portions of water. The supplementary materials comprise the following components in portion by weight: 1.5 to 2.5 portions of salt, 0.003 to 0.01 portion of nitrite, and 0.1 to 0.5 portion of tripolyphosphate. The preparation method comprises the following steps: forming comminuted meat from the lean mutton, and adding the salt and nitrite for even curing; adding the tripolyphosphate, carrying out the intensive stirring for even mixing, and adding the vegetable oil and carrying out the stirring; carrying out the vacuum filling; carrying out the drying; and carrying out the cooling. The invention takes the lean mutton and the vegetable oil as raw materials for the first time. As the vegetable oil replaces fat, the special mutton smell is removed, and the taste is good. The mutton sausage not only enriches the varieties of sausages, but also provides wider approaches for the deep processing of mutton.

Owner:CHINA MEAT RES CENT

Process for producing frozen pasty squid

A technology for preparing the frozen squid particles includes such steps as removing skin from squid, slicing, adding it to the aqueous solution of sodium hexametaphosphate, homogenizing, regulating pH=8-10 or 2-4, laying aside, regulating pH=4-5, laying aside, centrifugal separation to obtain squid meat deposit, mixing it with cane sugar, sorbitol and tripolyphosphate, and freezing.

Owner:OCEAN UNIV OF CHINA

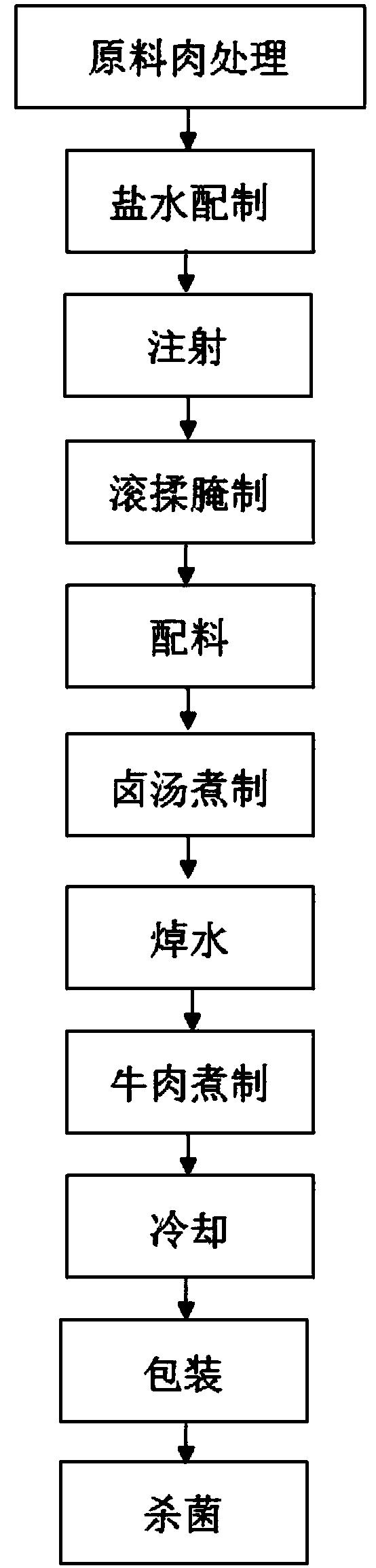

Method for processing quality of sauced beef

InactiveCN107751807AImprove qualityAdd flavorClimate change adaptationFood scienceSodium lactateFlavor

The invention discloses a method for processing quality of sauced beef and belongs to the technical field of food processing. The method comprises the following steps: treating raw material beef, preparing salty water, injecting the salty water into the beef, performing kneading pickling, preparing materials, boiling stewing soup, blanching the beef with water, boiling the beef, cooling, packaging, sterilizing, and cooling with flowing cold water. According to the method, a pickling liquid is prepared from tripolyphosphate, salt, nitrite, sodium lactate, TG (Triglyceride), fish steaming soy sauce, water and the like, and the beef is kneaded and pickled with the pickling liquid and is boiled together with a condiment bag, a stewing condiment bag and water, so that not only is the flavor improved, but also the yield rate is increased, and the taste and the quality stability are improved; conventional processing procedures are simplified, processing process parameters are defined, and meanwhile a composite water retaining agent is added; due to adoption of phosphate, glutamine transaminase and sodium lactate, the yield rate of the sauced beef can be effectively increased, and the texture stability of the sauced beef is effectively improved; through sterilization, the shelf life of the product is effectively prolonged, and the product satiability is improved.

Owner:JIANGSU YUNRUN MEAT WARE CO LTD

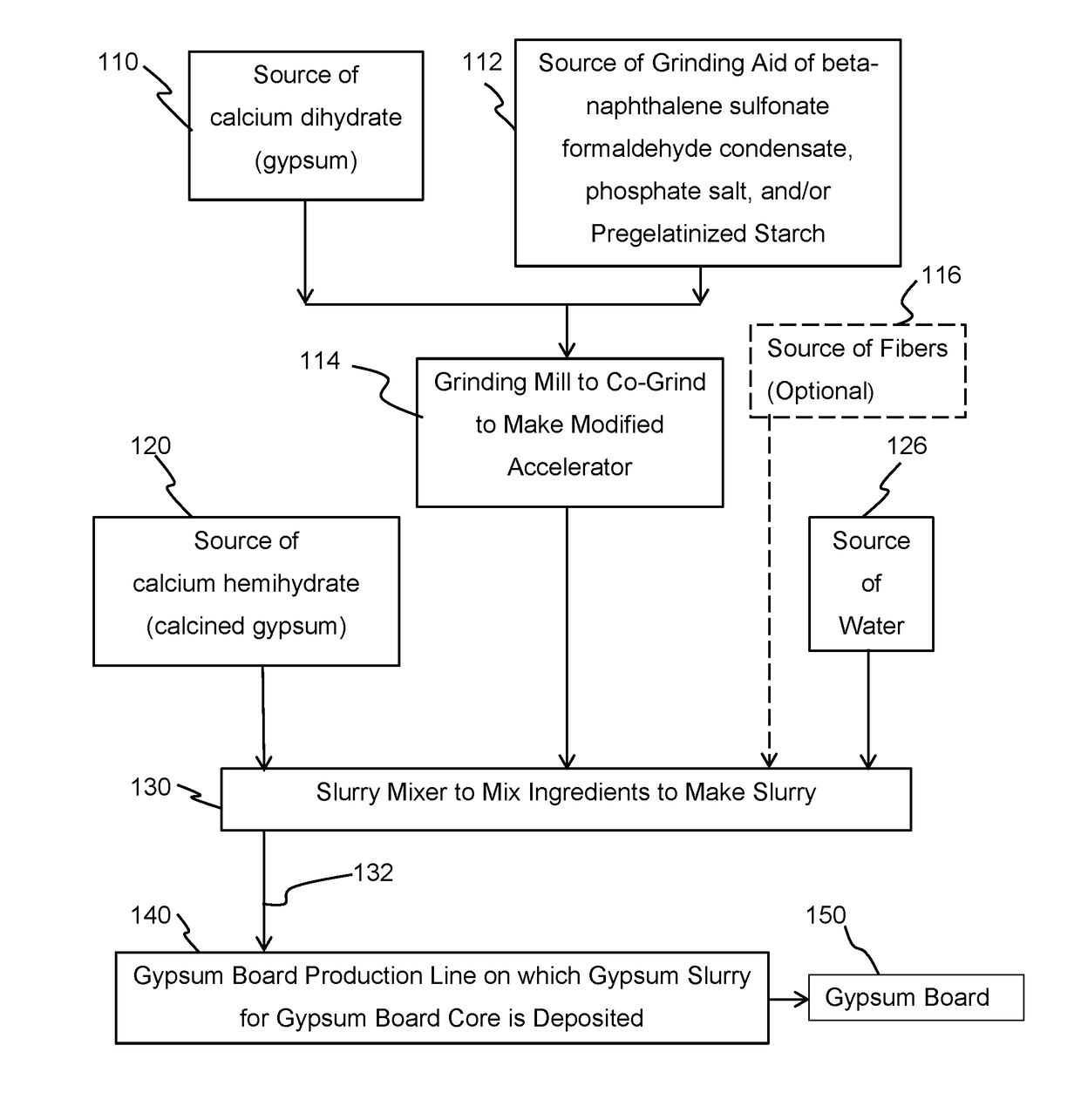

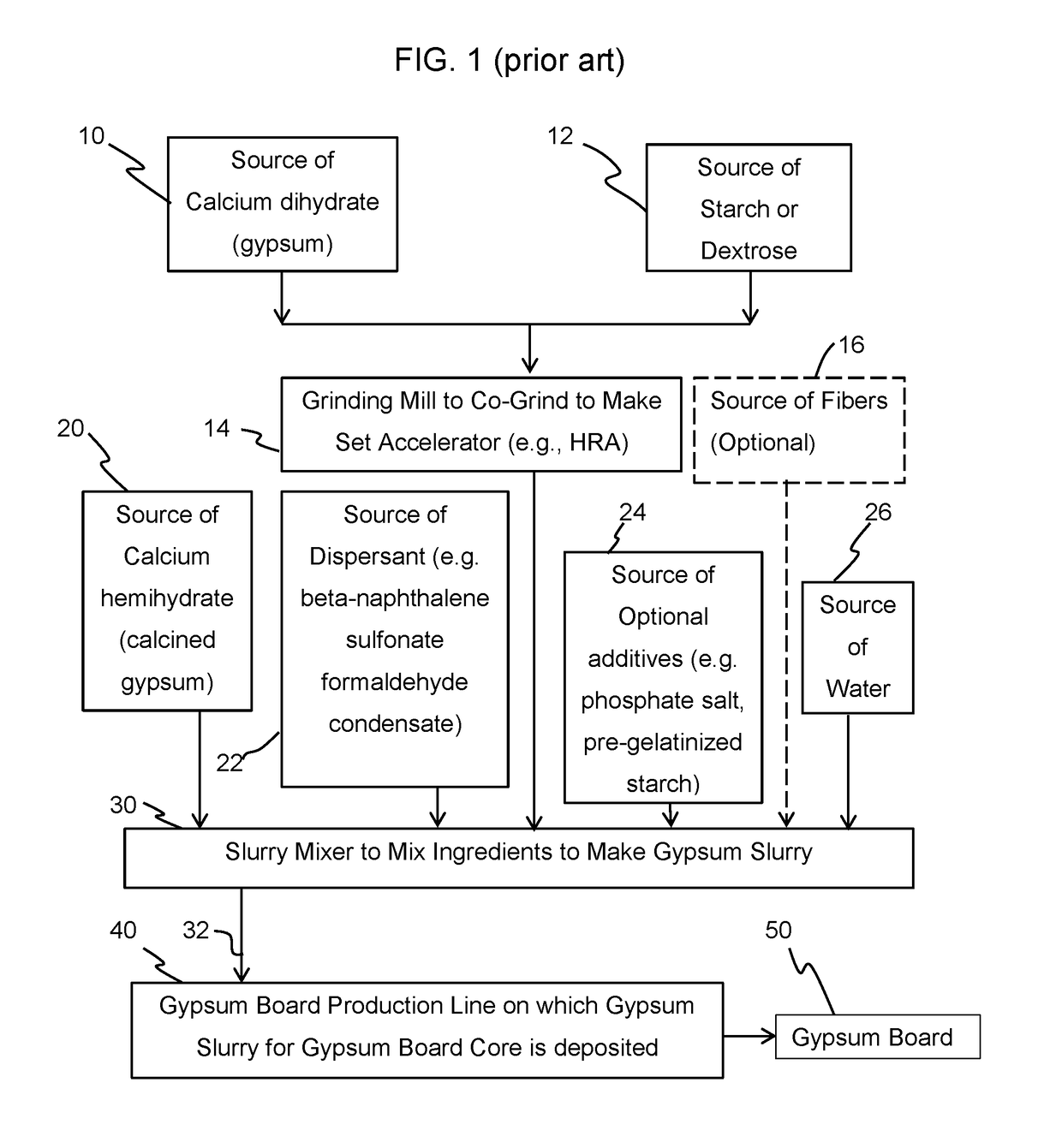

Gypsum set accelerator and method of preparing same

A modified gypsum set accelerator and a method of preparing the same is provided, which includes dry loose finely ground particles of a mixture of ground dry calcium sulfate dihydrate and a grinding aid selected from one or more of beta-naphthalene sulfonate formaldehyde condensate, trimetaphosphate phosphate salt, tripolyphosphate salt, tetra-pyrophosphate salt, and pregelatinized starch.

Owner:UNITED STATES GYPSUM CO

Use of inositol-tripyrophosphate in treating tumors and diseases

InactiveUS20060106000A1Increasing regulated delivery of oxygenLowering affinity for oxygenBiocidePhosphorous compound active ingredientsDiseaseRadiation sensitivity

Inositol-tripyrophosphate is an allosteric effector of hemoglobin due to its ability to cross the plasma membrane of red blood cells and deliver oxygen to solid tumors, by lowering the oxygen affinity of the hemoglobin of red blood cells. The present invention is directed to the use of inositol-tripyrophosphate to reduce hemoglobin's affinity for oxygen in circulating red blood cells. The present invention is further directed to the use of inositol-tripyrophosphate to inhibit angiogenesis and enhance radiation sensitivity of hypoxic tumors. The present invention is further directed to the use of inositol-tripyrophosphate to enhance PO2 in hypoxic tumors.

Owner:NORMOXYS

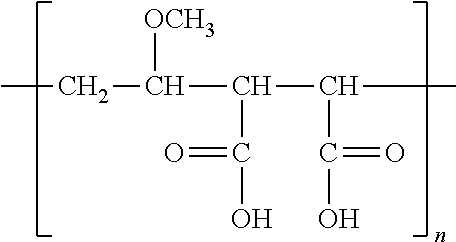

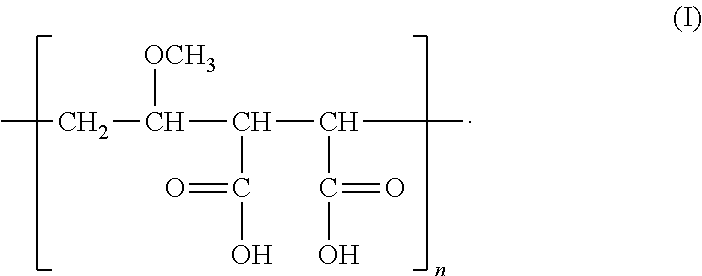

Amphiprotic starch graft copolymer and its one-step preparing process

A process for preparing the graft copolymer of amphiprotic starch prepared by one-step method includes such steps as preparing amphiprotic starch by both cationic and anionic reaction at 20-60 deg.C, where mixed water-alcohol solvent is used as reaction medium, tripolyphosphate or pyrophosphate as anionic reagent and 3-Cl-dihydroxytrimethylamine hydrochloride as cationic reagent, the graft copolymerizing between amphiprotic starch and acrylamide at 5-60 deg.C in water phase, and cationic reacting for the graft chain of said graft copolymer at 2-50 deg.C in water phase. Its advantages are better network structure, and high stability.

Owner:SOUTH CHINA UNIV OF TECH

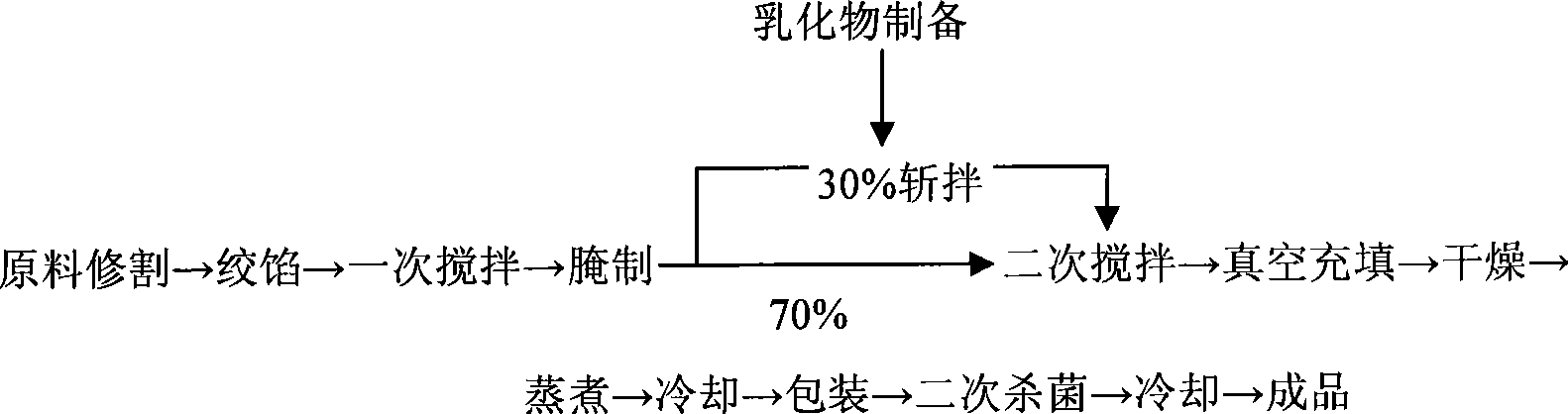

Islamic beef sausage and preparation method thereof

The invention discloses an Islamic beef sausage and a preparation method thereof. The Islamic beef sausage comprises the following raw materials in portion by weight: 50 to 80 portions of lean beef, 20 to 50 portions of emulsified substance, and 2 to 25 portions of water, wherein the emulsified substance is prepared from isolated soybean protein, beef fat and water according to the weight ratio of 1:(2 to 6):(2 to 6). The supplementary materials comprise the following components in portion by weight: 1.5 to 2.5 portions of salt, 0.003 to 0.01 portion of nitrite, and 0.1 to 0.5 portion of tripolyphosphate. The Islamic beef sausage is formed through the steps of twisting, emulsified substance preparation, mixing by chopping, stirring, vacuum filling, drying and cooking, and the like according to the recipe. The Islamic beef sausage takes the beef and the beef fat as raw materials so as to keep the original taste of beef. In addition, the addition of the emulsified substance covers the cowy smell of the beef fat, improves the taste, and simultaneously facilitates the digestion and absorption for a human body. The Islamic beef sausage explores a new way for the application of the beeffat to the Islamic meat products.

Owner:CHINA MEAT RES CENT

Metal surface liquid rust inhibitor

InactiveCN104746063APerformance Environmental SafetyImprove rust resistanceMetallic material coating processesEnvironmental resistanceRare earth

The invention discloses a metal surface liquid rust inhibitor, and especially relates to a liquid rust inhibitor for a railway vehicle water sandblast rust removal technology, and a preparation method and a use thereof. The metal surface liquid rust inhibitor comprises 8-10wt% of a main film forming agent, 3-5wt% of an alkaline corrosion inhibitor, 5-10wt% of a rust inhibitor, 1-20wt% of a promoter, 0.5-1wt% of a surfactant, and the balance of water, the main film forming agent is tripolyphosphate, the alkaline corrosion inhibitor is rare earth petroleum sulfonate, the rust inhibitor is organic amine, and the promoter is soda ash. The preparation method is characterized in that all components are mixed with water in proportion, and are uniformly stirred. When the metal surface liquid rust inhibitor is used, the metal surface liquid rust inhibitor is diluted by water according to a weight ratio of 1:2-1:3, and the obtained solution is used for spraying the surface of a railway vehicle obtained after water sandblast rust removal treatment; or the metal surface liquid rust inhibitor is added to circulating water for the water sandblast rust removal technology according to a weight ratio of 1:8-1:10, and the obtained liquor is directly used to carry out water sandblast rust removal treatment on the surface of the railway vehicle. The liquid rust inhibitor has the characteristics of low cost, safety, environmental protection, good rust inhibition effect and excellent welding performance, and completely adapts to the rust inhibition requirements of the mechanical automatic water sandblast technology of a rail wagon or an ultra large structural member.

Owner:董林祥

Preparation method of cadmium removal agent of thiolated chitosan microsphere

ActiveCN104707573AHigh selective adsorptionPromote chelationOther chemical processesWater/sewage treatment by sorptionCross-linkMicrosphere

The invention discloses a preparation method of a cadmium removal agent of a thiolated chitosan microsphere. The method comprises the steps of imprinting chitosan with a cadmium ion, then carrying out cross-linking forming with tripolyphosphate, eluting the cadmium ion with hydrochloric acid to prepare a chitosan microsphere, and modifying with carbon disulfide under an alkaline condition to prepare a finished product. A material prepared by the method has good absorption and chelation effects on the cadmium ion, is used for cadmium wastewater treatment, and can allow wastewater to reach the standard for discharge and recover the cadmium ion in the water.

Owner:XIAN UNIV OF SCI & TECH

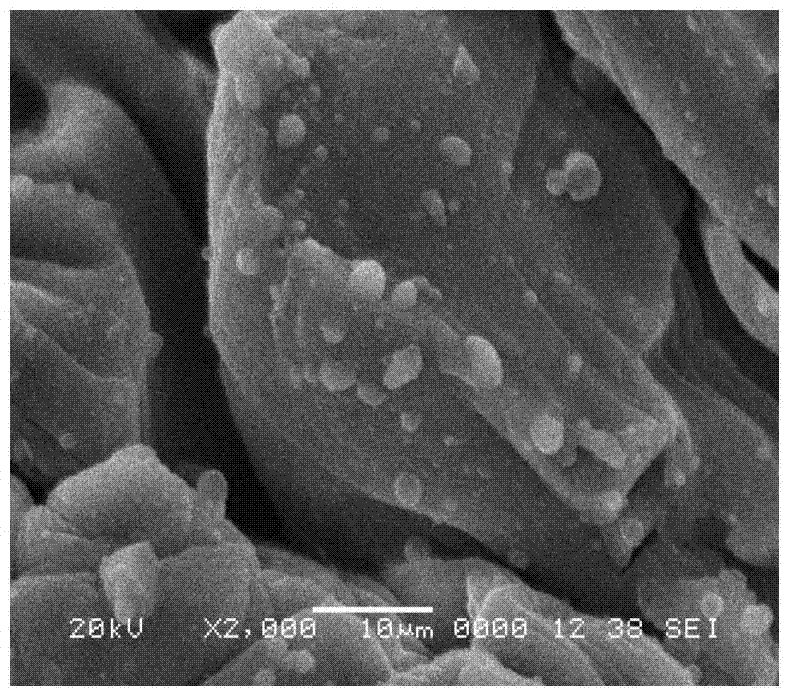

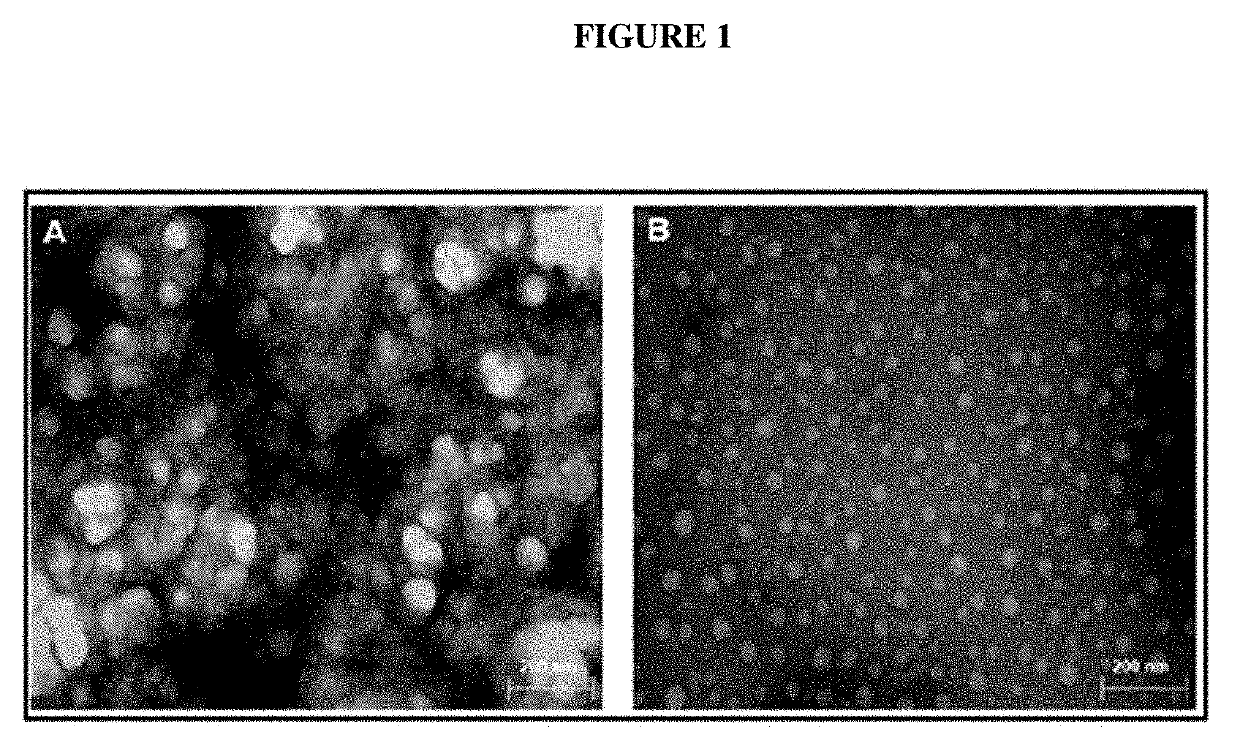

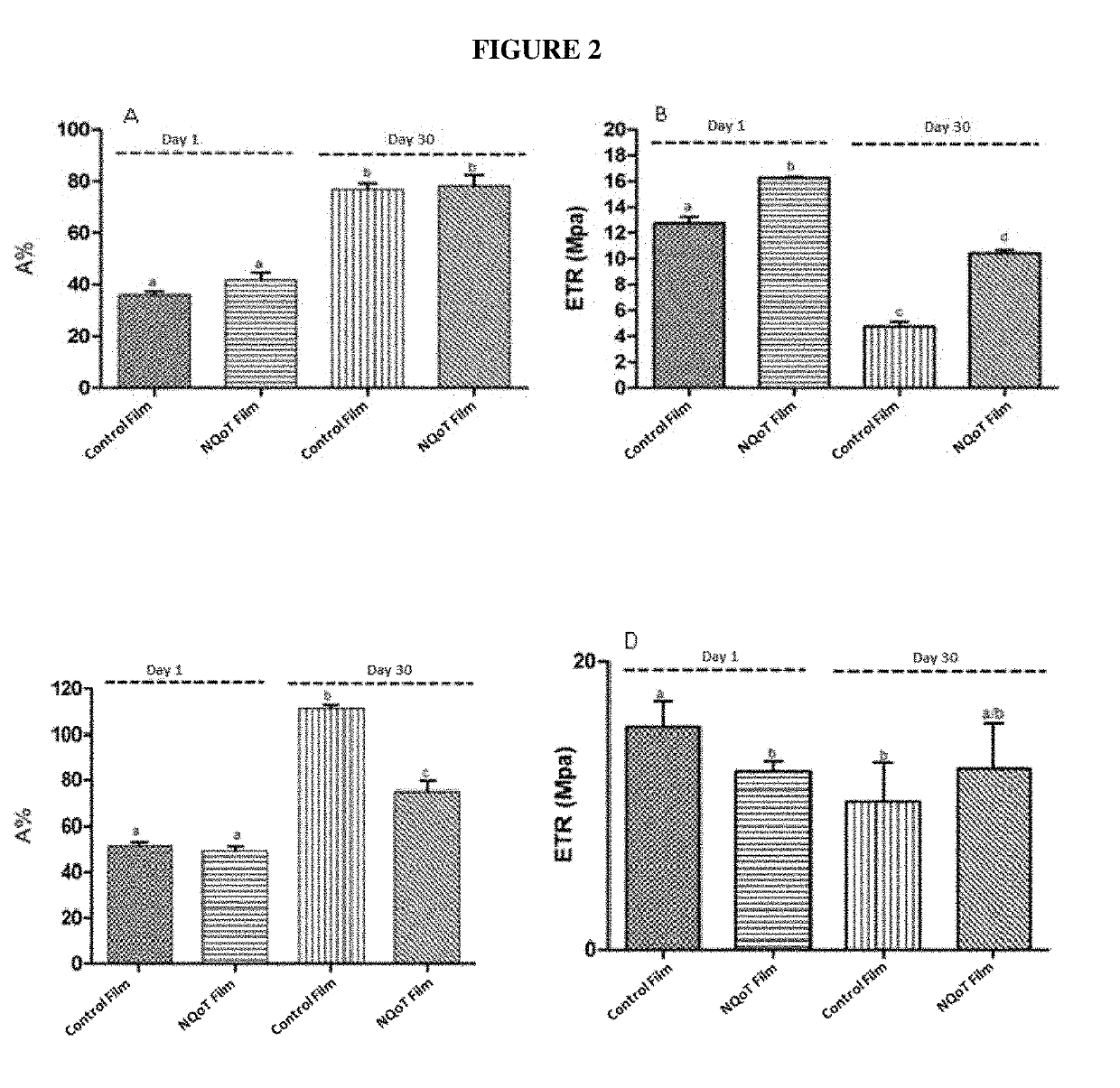

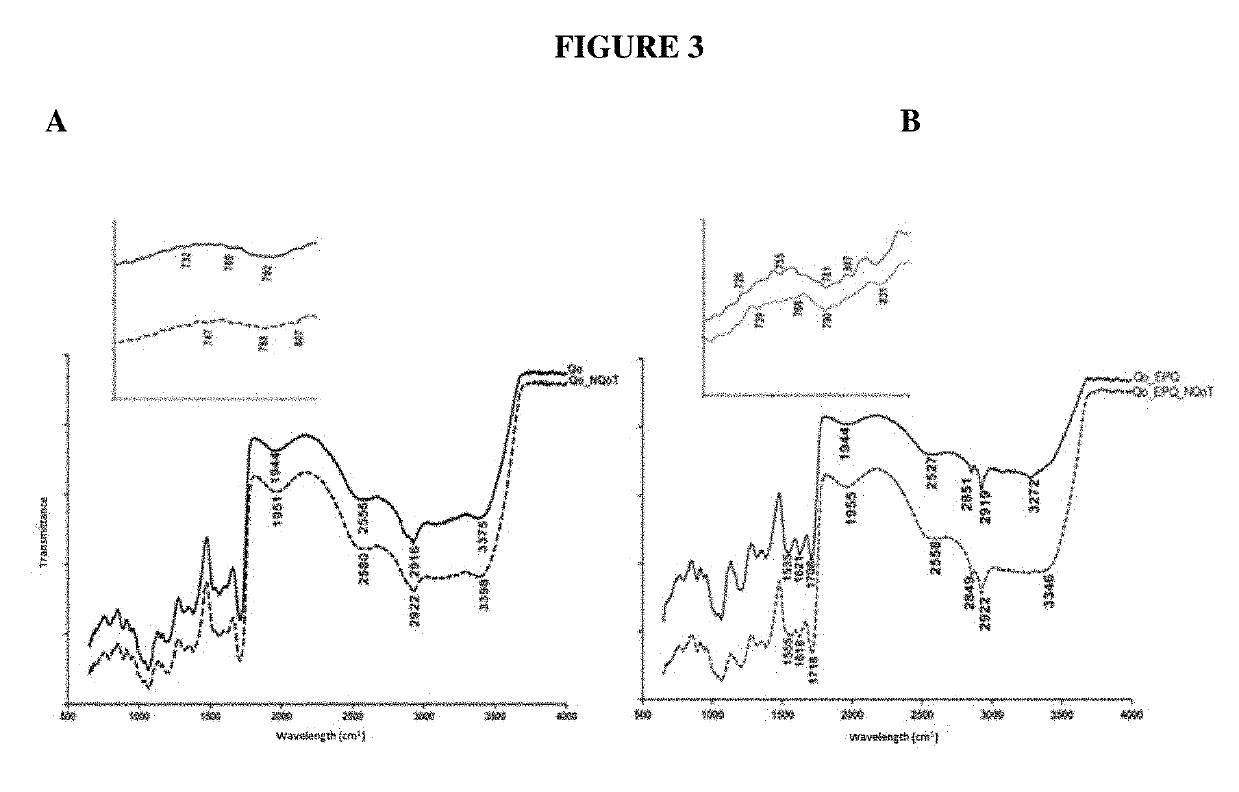

Edible bio-active films based on chitosan or a mixture of quinoa protein-chitosan; sheets having chitosan-tripolyphosphate-thymol nanoparticles; production method; bio-packaging comprising same; and use thereof in fresh fruit with a low ph

InactiveUS20190281845A1Extended shelf lifeImprove mechanical propertiesFlexible coversWrappersNanoparticleFilm base

Owner:UNIVERSITY OF CHILE

Method for regenerating ATP(adenosine triphosphate) through enzyme method

InactiveCN105463043ALow costComply with temperature requirementsTransferasesFermentationPhosphoric acidHeterogeneous source

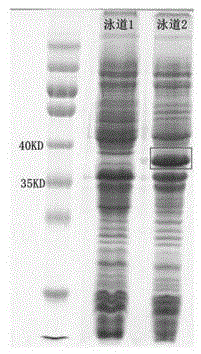

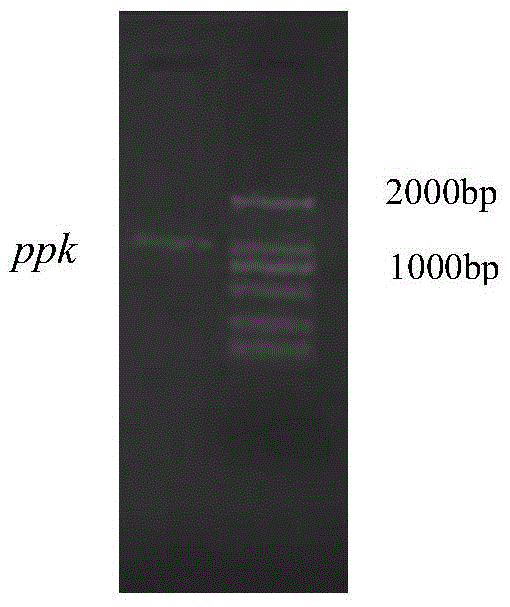

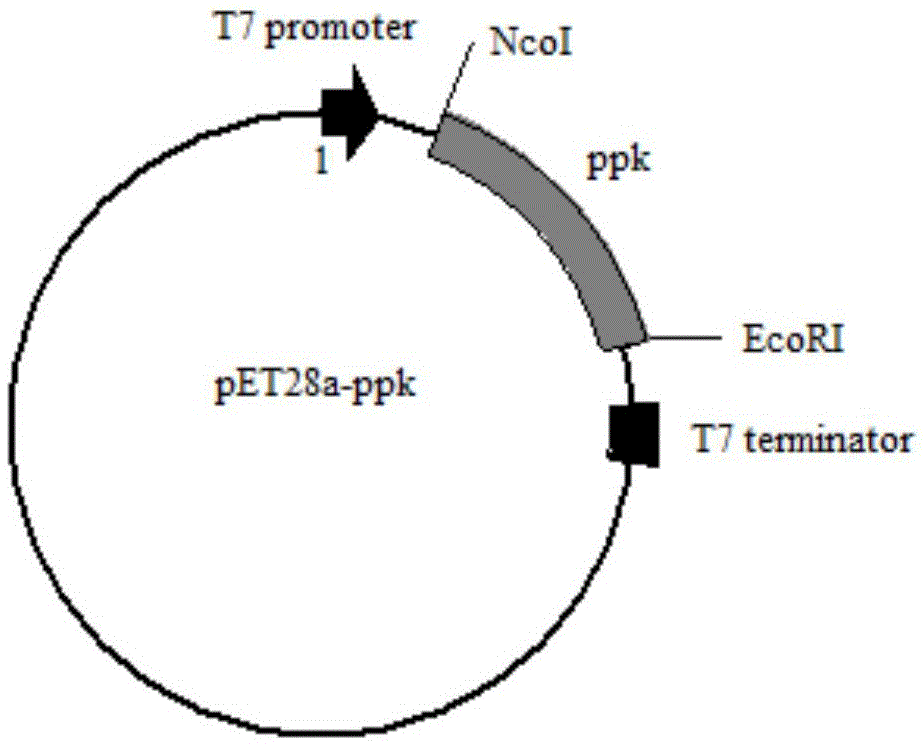

The invention relates to a method for regenerating ATP(adenosine triphosphate). A heterogeneous source is used for expressing polyphosphate kinase, and under catalyzing of polyphosphate kinase, polyphosphates with the low polymerization degree are used as phosphoric acid donors for regenerating ATP. Compared with an existing ATP regeneration method, adopted polyphosphate kinase is a normal-temperature enzyme, can be combined with multiple enzymes for promoting reaction coupling, and adopts a tripolyphosphate, a tetrapolyphosphate and a hexametaphosphate as the phosphoric acid donors, these polyphosphates are low in polymerization degree, common, easy to obtain and low in price, on the basis of simplifying the ATP regeneration process, feasibility of ATP regeneration is improved, and the ATP regeneration cost is reduced; activity of a PPK enzyme is not inhibited by polyphosphate concentration, and possibility is provided for industrialized large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

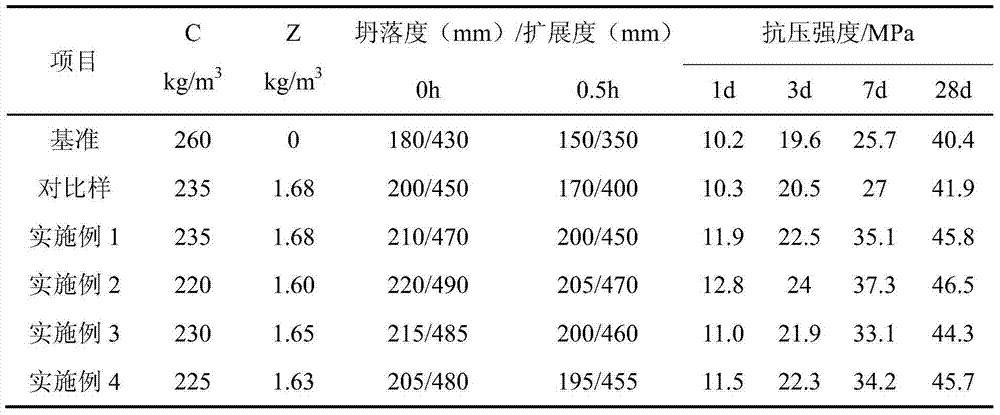

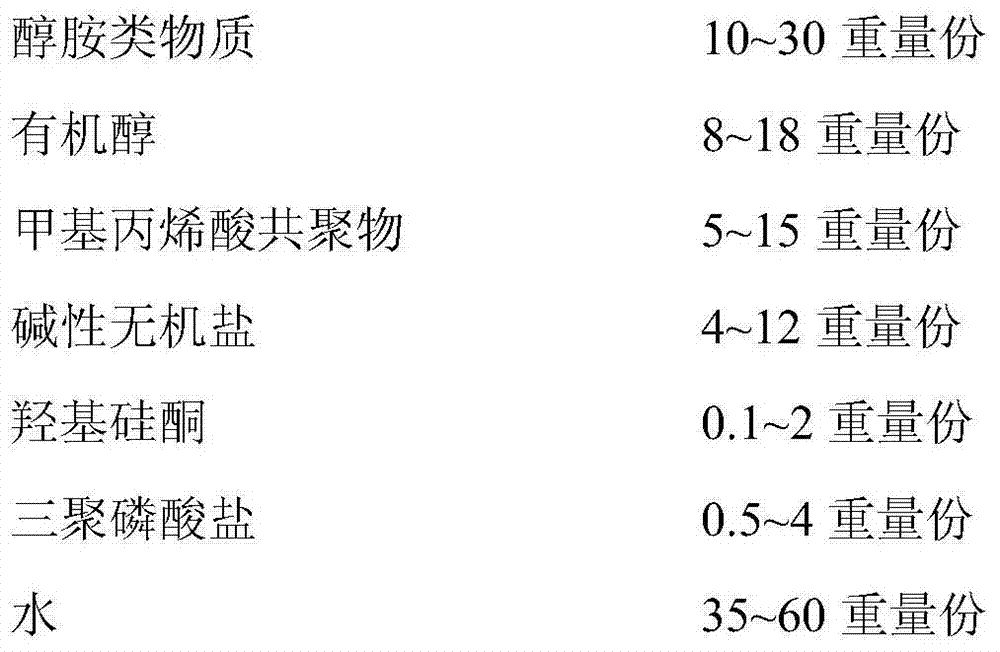

Concrete synergist and preparation method thereof

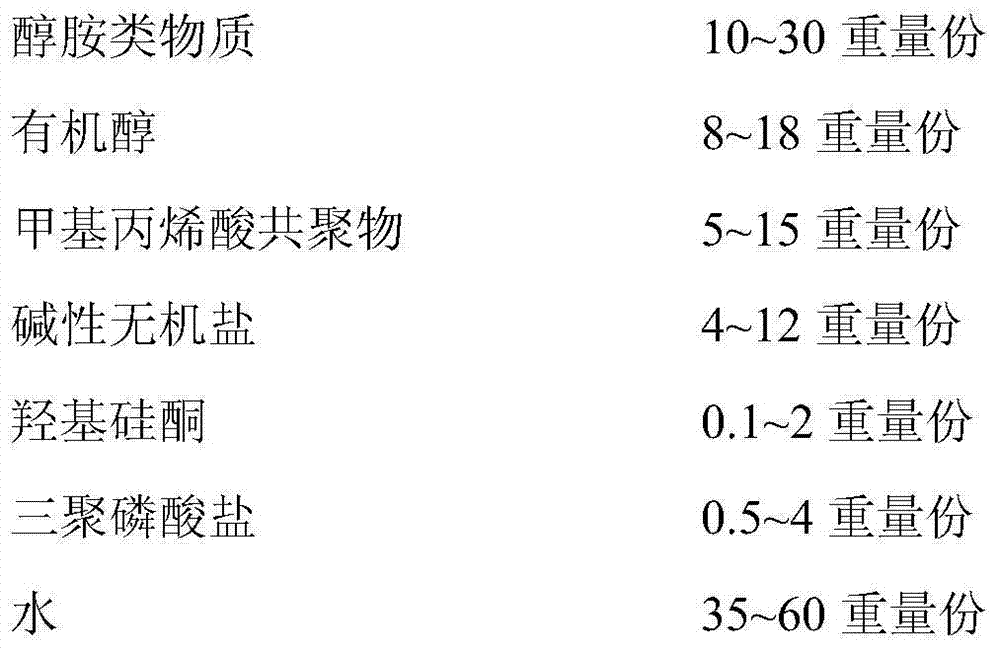

The invention discloses concrete synergist and a preparation method thereof. The concrete synergist comprises, by weight, 10-30 parts of alcamines substances, 8-18 parts of organic alcohol, 5-15 parts of methacrylic acid copolymers, 4-12 parts of alkaline inorganic salt, 0.1-2 parts of hydroxyl silicones, 0.5-4 parts of tripolyphosphate and 35-60 parts of water, and the methacrylic acid copolymers refer to one or two copolymers among methacrylic acid-hydroxyethyl acrylate copolymer co-MAA-HEA of which the molecular weight is 50000-6000 and the block proportion MAA: HEA is (3-4): 1, methacrylic acid-hydroxy-propyl acrylate copolymer co-MAA-HPA of which the molecular weight is 40000-50000 and the block proportion MAA: HPA is (4-5): 1 and methacrylic acid-ethyl acrylate co-MAA-EA of which the molecular weight is 30000-40000 and the block proportion MAA: EA is (4-6): 1. The concrete synergist is free from strong odor and toxicity, high in efficiency and environmental friendly.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Liquid antirusting agent used in railway vehicle water sandblasting antirusting process as well as preparation method and application thereof

ActiveCN102011113AImprove welding effectImprove securityMetallic material coating processesWater useSulfonate

The invention discloses liquid antirusting agent used in a railway vehicle water sandblasting antirusting process as well as a preparation method and an application thereof. The liquid antirusting agent comprises the following components by weight percent: 8-10% of main film-forming agent, 3-5% of alkaline corrosion inhibitor, 5-10% of antirusting agent, 1-2% of accelerating agent, 0.5-1% of surface active agent and the balance water, wherein the main film-forming agent is tripolyphosphate, the alkaline corrosion inhibitor is oil rare earth sulfonate, the antirusting agent is organic amine and the accelerating agent is calcined soda. In the preparation process, each component is evenly mixed with water according to the ratio. When in use, the liquid antirusting agent is diluted with water at the ratio of (1:2)-(1:3) and is used for spraying the surface of railway vehicles subject to water sandblasting antirusting; or the liquid antirusting agent is added to the circulating water used in the water sandblasting antirusting process at the weight ratio of (1:8)-(1:10) and is directly used for carrying out water sandblasting antirusting on the surface of the railway vehicles. The liquid antirusting agent is characterized by low cost, safety, environmental friendliness, favorable antirusting effect, excellent welding performance and the like, and fully meets the requirements of the mechanical and automatic water sandblasting process of the railway vehicles or ultra large structures.

Owner:CRRC YANGTZE CO LTD

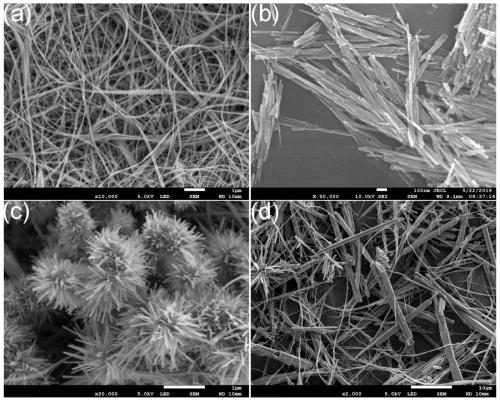

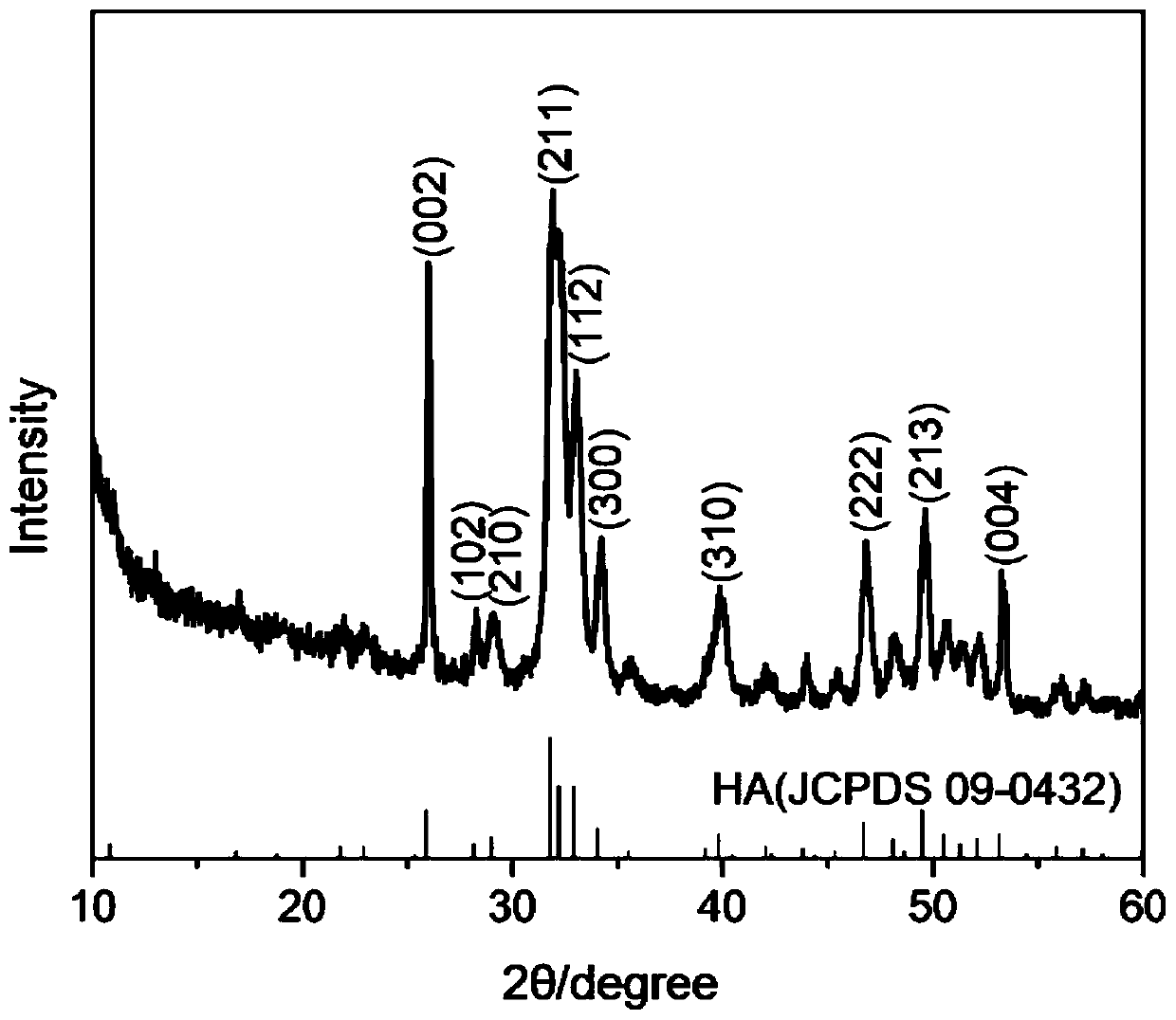

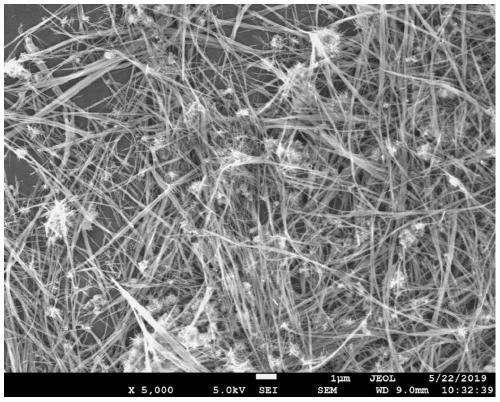

Method for regulating morphology of hydroxyapatite micro-nanomaterial by using phosphorus source

The invention relates to a method for regulating the morphology of a hydroxyapatite micro-nanomaterial by using a phosphorus source. The method comprises the following steps: mixing anhydrous ethanoland palmitic acid, adding an aqueous solution of a soluble calcium salt and an aqueous solution of a strong alkali, and performing magnetic stirring until uniformity in order to prepare a calcium palmitate precursor; adding an aqueous solution of various phosphorus sources such as a phosphate dodecahydrate, a trimetaphosphate, a tripolyphosphate, and a hexametaphosphate to obtain a reaction solution, adding the reaction solution into a hydrothermal kettle, and carrying out a solvothermal reaction; and washing and drying the obtained reaction product to obtain the hydroxyapatite micro-nanomaterial with various morphologies such as a ultra-long nanowire, a nano-short rod, a petal-like microsphere and a micro-tube. The method can be used to conveniently and quickly obtain the hydroxyapatite micro-nanostructure with the controlled morphology, and the hydroxyapatite micro-nanomaterial can be applied to many fields of bone tissue repairing, suture, hemostatic dressings, adsorption bioactivesubstances, drug loading and release, bone filling and cell / drug loaded implants according to actual needs.

Owner:SHANDONG JIAOTONG UNIV

Low temperature beef steak and preparation method thereof

The invention provides low-temperature beefsteak which is obtained by thermally processing the following raw materials and auxiliary materials at low temperature. The raw materials comprise the following ingredients by weight parts: 100 parts of beef and 10-15 parts of water; the auxiliary materials comprise the following ingredients by weight parts: 1.5-2.3 parts of common salt, 0.5-1.5 parts of white sugar, 0.1-0.3 part of tripolyphosphate, 0.2-1 part of soybean protein, 0.2-0.4 part of flavor essence, 0.5-1 part of smoke solution, 0.3-0.5 part of white pepper powder, 0.15-0.3 part of nutmeg powder, 0.3-0.5 part of onion powder and 0.1-0.3 part of red pigment. Simultaneously, the invention further provides a preparation method of the low-temperature beefsteak. The beefsteak is processed by the processing method of the low-temperature meat product. As the fumeol is used and the temperature of heat processing is relatively low, the method not only preserves the tenderness and flavor of the high-temperature beefsteak, but also avoids carcinogen, thus providing wider means for beef deep-processing.

Owner:CHINA MEAT RES CENT

Pearl meatball (glutinous rice meatball) and preparing method for the same

The invention relates to a pearl meatball (glutinous rice meatball) and the ingredients of the pearl meatball comprise lean meat, fat lining, salt, sodium tripolyphosphate, white sugar, monosodium glutamate, scallion, ginger, yellow rice wine, edible fungus, soybean protein powder, starch maize, wheat flour, glutinous rice, ice water and vegetable. The preparing method comprises: respectively mincing the lean meat and fat lining into meat stuffing; adding the salt, the white sugar, the polyphosphate and the like to mix well; standing; adding soybean protein powder, starch maize, wheat flour, and the fine minced scallion ginger, edible, fungus and vegetables; stirring to mix well; molding by handwork or a machine,; preparing to meatball; soaking the glutinous rice with drinking water until soft; then draining the water; spreading out; allowing the surrounding of the meatball to stick to the glutinous rice evenly and freezing quickly. The peal meatball can be cooked for eating easily only by steaming above boiling water without need of unfreezing; can also be directly cooked by steaming, frozen quickly after cooled, and heated by microwave for eating. The pearl meatball of the invention has the advantages of attractive appearance, good mouthfeel, abundant nutrition and convenient eating.

Owner:天津宝迪农业科技股份有限公司

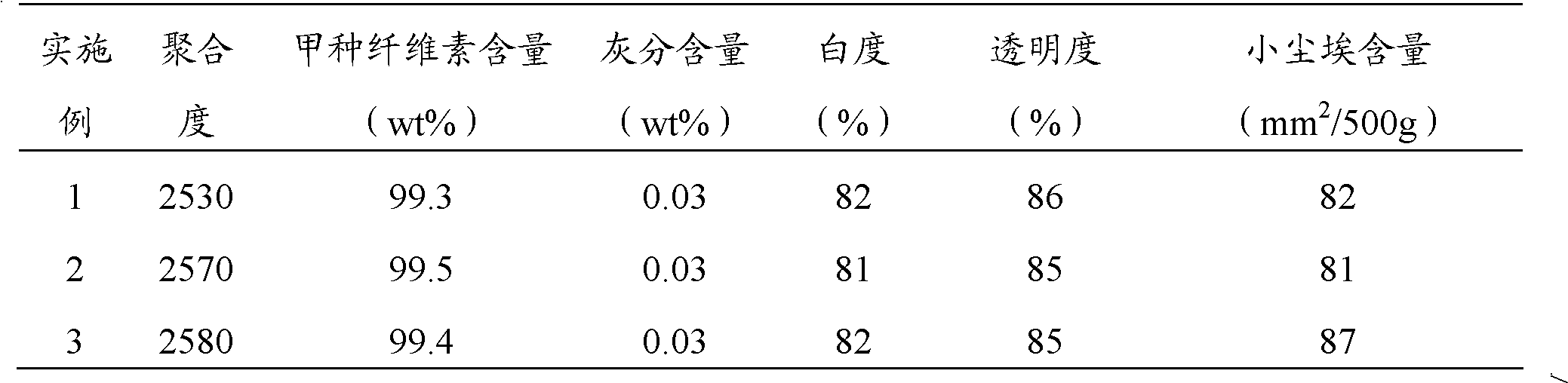

Cotton pulp with high degree of polymerization and production method thereof

InactiveCN102383332AReduce contentPulp bleachingPulping with inorganic basesMetalDegree of polymerization

The invention relates to the technical field of cotton pulp, in particular to cotton pulp with a high degree of polymerization and a production method thereof. The production method comprises the following steps: carrying out breaking and opening as well as decontamination to cotton linter material to obtain high-quality cotton linter; mixing the high-quality cotton linter with cooking liquor and then cooking the mixture to obtain a sizing agent, wherein the cooking liquor contains alkali and tripolyphosphate; and carrying out bleaching, acid treatment and paper manufacture with pulp to the sizing agent to obtain the cotton pulp with a high degree of polymerization. With the production method provided by the invention, the cotton pulp with low ash content and high transparency is obtained, and the production method is applicable to production and processing of products with stricter requirements on metal ions. The invention also provides the cotton pulp with a high degree of polymerization of 23000-2700, the content of alpha cellulose of more than or equal to 99 weight percent, whiteness is more than or equal to 80 percent, ash content is less than or equal to 0.04 weight percent, and transparency is more than or equal to 80 percent.

Owner:ANHUI SNOW DRAGON FIBER TECH

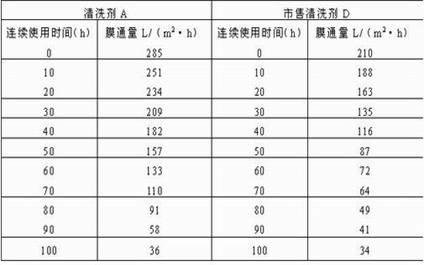

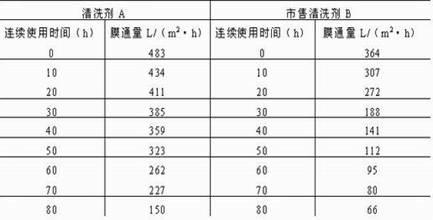

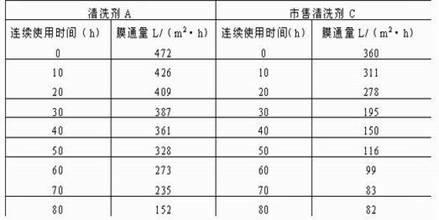

Novel membrane cleaning agent

InactiveCN101972607ARestore filter functionReduce the probability of foulingSemi-permeable membranesCleansing AgentsSolvent

The invention discloses novel membrane cleaning agent, which is prepared by mixing the following components in percentage by weight: 10 to 25 percent of wetting agent, 10 to 20 percent of solubilizer, 20 to 35 percent of chelant, 35 to 55 percent of surfactant and 5 to 12 percent of bioactive enzyme, wherein the wetting agent may be tripolyphosphate or sodium hexametaphosphate; the solubilizer may be alkaryl polyether polyol or modified polyether; the chelant may be ethylene diamine tetraacetic acid, diethyltriamine pentaacetic acid or aminotriacetic acid; the surfactant may be sodium dodecyl benzene sulfonate or Tween 20; and the bioactive enzyme may be KAC or protease. The novel membrane cleaning agent can permeate dirt quickly and undergoes a chelation reaction, so the cleaning time is saved, the damage caused by the cleaning agent to the membrane surface is relieved, and the service life of the member is prolonged.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

Stannous salt and sodium tripolyphosphate oral care compositions and methods

Oral care compositions containing a stannous salt and sodium tripolyphosphate are provided where stannous tripolyphosphate ionic intermediates comprise less than about 1% of the compositions Tetrasodium pyrophosphate, a methylvinyl ether-maleic anhydride copolymer and / or a silica oral polishing agent may be added for further efficacy. In a single phase blend, the oral care composition may be effectively limited to comprise less than about 10% water. In a dual-phase blend a mixture having the stannous salt in a first phase and the sodium tripolyphosphate in a second phase may be generated from a dual chamber storage tube (with each phase provided from a separate chamber) immediately prior to dental care usage.

Owner:COLGATE PALMOLIVE CO

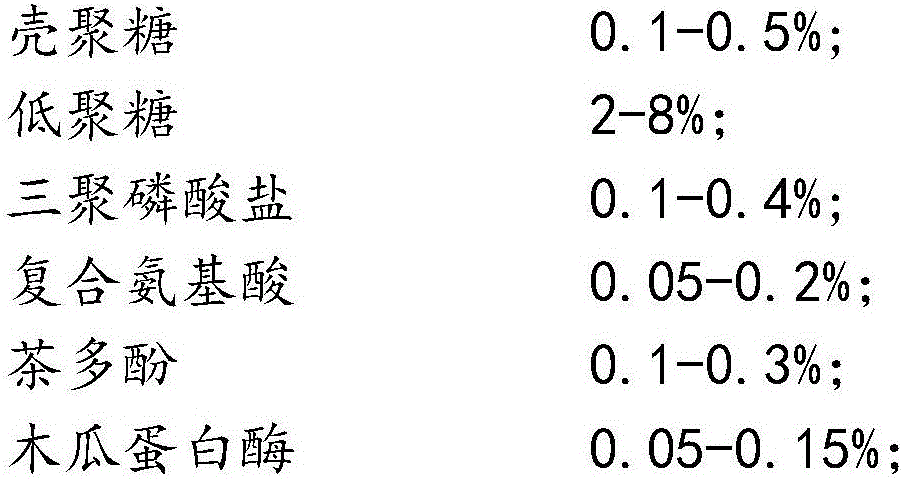

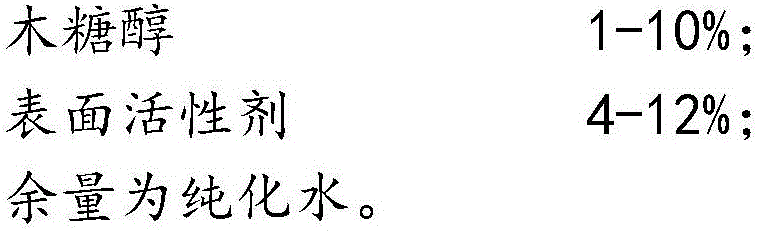

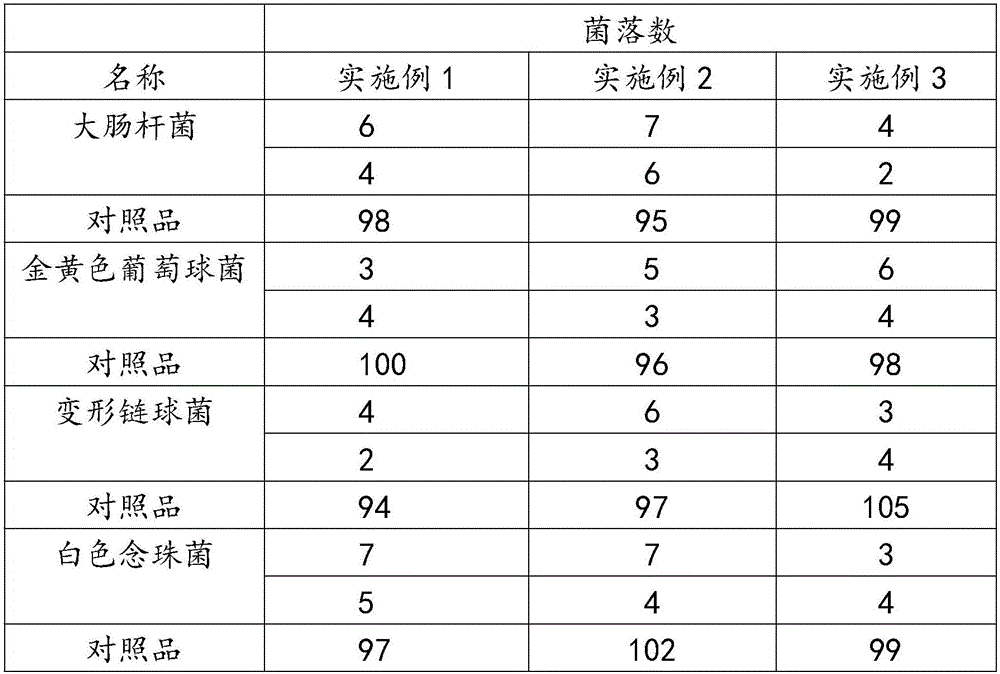

Mouthwash and preparation method thereof

ActiveCN105919829AFix stability issuesSolve temperature problemsAntibacterial agentsCosmetic preparationsSide effectDissolution

The invention discloses mouthwash and a preparation method thereof. Through being metered by the total mass of 100 percent, the mouthwash is prepared from the following raw materials in percentage by mass: 0.1 to 0.5 percent of chitosan, 2 to 8 percent of oligose, 0.1 to 0.4 percent of tripolyphosphate, 0.05 to 0.2 percent of compound amino acid, 0.1 to 0.3 percent of tea polyphenol, 0.05 to 0.15 percent of papain, 1 to 10 percent of xylitol, 4 to 12 percent of surfactants and the balance purified water. The raw materials are weighed according to the mass ratio; through the steps of dissolution, ultrasonic treatment, mixing, wet and hot sterilization and the like; the mouthwash is obtained. The mouthwash has the characteristics that the effective bacteriostasis is achieved; no toxic and side effects exist; harmlessness is realized on the normal flora in the oral cavity; the biosafety is high.

Owner:GUIZHOU YANGSHENG MEDICAL INSTR

Cleaning compositions

InactiveUS6372707B1Easy to handle and dispense into washloadEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolubilityParticulates

A tablet of compacted particulate cleaning composition which contains surfactant and detergency builder, and is suitable for fabric washing, also includes water-insoluble, water-swellable polymeric material, and disintegration-promoting particles containing at least 40% (by weight of the particles) of one or more materials selected from:compounds with a water-solubility exceeding 50 grams per 100 grams waterphase 1 sodium tripolyphosphatesodium tripolyphosphate which is partially hydrated so as to contain water of hydration in an amount which is at least 0.5% by weight of the sodium tripolyphosphate in the disintegration-promoting particles.

Owner:LEVER BROTHERS

Method for preparing tripolyphosphate and hexametaphosphate products by using byproduct pyrophosphate

InactiveCN104118854ASolve the preparation of tripolyphosphateSolve the characteristicsPhosphorus compoundsPhosphoric acidPyrophosphate

The invention relates to transformation of phosphates, and particularly relates to a method for preparing tripolyphosphate and hexametaphosphate products by taking pyrophosphates (obtained in the process of recycling phosphorus-containing wastes generated in organophosphorus pesticide production) as a main raw material. The method for preparing the tripolyphosphate and / or hexametaphosphate products is characterized by comprising the steps of pretreating the pyrophosphates used as the raw material, adding phosphoric acid and a conditioning agent and controlling polymerization temperature.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Frozen vegetable burger and preparation method thereof

The invention relates to a frozen vegetable burger comprising stuffing and a wrapping material, wherein the stuffing is prepared from the following raw materials: raw material meat, vegetables, salt, white granulated sugar, tripolyphosphate, monosodium glutamate, ginger powder, chilli powder, five-spice powder, soy proteins, corn starches and ice water; and the wrapping material is a paste layer and is prepared from the following raw materials by weight ratio: wheat flour, corn flour, milk powder, glutinous rice flour, the salt, salad oil and water. The meat stuffing and the vegetables are used as main raw materials, therefore, the prepared frozen vegetable burger has more unique features compared with the general meat burger, not only has delicious taste, but also has rich nutrient components; in addition, the preparation method is simple and the movable multipurpose socket board is suitable for families and industrialized production.

Owner:天津宝迪农业科技股份有限公司

Protein delivery system of specific targeting macrophages

InactiveCN105983100ADoes not affect the identification mechanismReduce releasePeptide/protein ingredientsPharmaceutical non-active ingredientsAntigenDisease

The invention discloses a yeast hollow beta-glucan shell wrapped GMP-BSA protein targeting macrophage delivery system. The system allows BSA to be coated in a yeast shell through using a compact layer formed through the electrostatic adsorption effect of chitosan (CS), tripolyphosphate (TPP), sodium alginate and BSA. GMP-BSA particles prepared in the invention have very good protein release behavior in in-vitro experiments, and can avoid protein loss. The particles highly specifically target the macrophages, such as Raw 264.7 cells, primary BMDM cells (primary bone marrow macrophages) and peritoneal macrophages (PEMs), and are not devoured by NIH3T3, AD293, HeLa, Caco-2 and other non-macrophage tumor cells, and neutral granulocytes in blood. The macrophages play a great role in the pathogenesis of various diseases, and are very important potential target spots. The macrophages are key antigen transfer cells, and are very important in vaccine design. The system can highly selectively deliver various proteins to the macrophages in a targeting manner, and also has very wide application prospect in the field of targeting drug administration and the field of macrophage vaccine design.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com