Cotton pulp with high degree of polymerization and production method thereof

A production method and technology with high degree of polymerization, applied in pulp bleaching, pulping with inorganic alkali, pulping with cellulose raw materials, etc., can solve the problems of unsuitable production and processing, low temperature and high ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] First, cotton linter raw materials with no three-filament and a maturity of 75% are opened and dry-type impurity removal to obtain fine-dried cotton linters. Among them, 70wt% of the cotton linter raw materials used are Type II cotton linters, 30wt % is Type III cotton linters;

[0065] The sodium hydroxide of 9.0wt% sodium hydroxide, the sodium tripolyphosphate of 1.1wt%, the JFC of 0.3wt% and the sodium sulfite of 0.2wt% that consumption is fine-dried cotton linters dry weight are formulated into cooking liquid at 60 ℃, and liquid ratio is 1:4.1, fully mixed with fine-dried cotton linters by cyclone separator spraying, and then squeezed by a screw press, then screw conveyed to steaming balls, in the steaming balls, fine-dried cotton linters and cooking liquid are mixed at room temperature for 40 minutes Carry out cooking, heat up to 108°C within 50 minutes, deflate for 15 minutes, then continue to heat up to 128°C within 30 minutes, and keep warm for 110 minutes;

[...

Embodiment 2

[0070] Firstly, cotton linter raw materials with no three-filament and a maturity of 71% are opened and dry-type impurity removal to obtain fine-dried cotton linters. Among them, 60wt% of the cotton linter raw materials used are Type II cotton linters, 40wt % is Type III cotton linters;

[0071] The sodium hydroxide of 9.1wt% sodium hydroxide, the sodium tripolyphosphate of 1.2wt%, the JFC of 0.3wt% and the sodium sulfite of 0.2wt% are formulated into cooking liquid at 60 ℃ with consumption being the dry weight of fine-dried cotton linters, and the liquid ratio is 1:4.2, fully mixed with fine-dried cotton linters by cyclone separator spraying, and then squeezed by a screw press, and then screwed to the steaming ball. After mixing for 40 minutes, heat up to 108°C within 50 minutes, deflate for 15 minutes, then continue to heat up to 126°C within 30 minutes, and keep warm for 110 minutes;

[0072] After cooking is finished, obtain the slurry after cooking, follow-up technologic...

Embodiment 3

[0075] First, cotton linter raw materials with no three-filament and a maturity of 76% are opened and dry-type impurity removal to obtain fine-dried cotton linters. Among them, 55wt% of the cotton linter raw materials used are Type II cotton linters, 45wt % is Type III cotton linters;

[0076] The sodium hydroxide of 9.1wt% sodium hydroxide, the sodium tripolyphosphate of 1.5wt%, the JFC of 0.3wt% and the sodium sulfite of 0.2wt% that consumption is fine-dried cotton linters dry weight are formulated into cooking liquid at 60 ℃, and liquid ratio is 1:4.2, sprayed by cyclone separator and fully mixed with fine dry cotton linters, and then squeezed by screw press, then screw conveyed to steaming balls;

[0077] The subsequent process flow is the same as that of Example 2, with only slight differences in process parameters. In this example, the acid concentration of the acid treatment is 1.3 g / L.

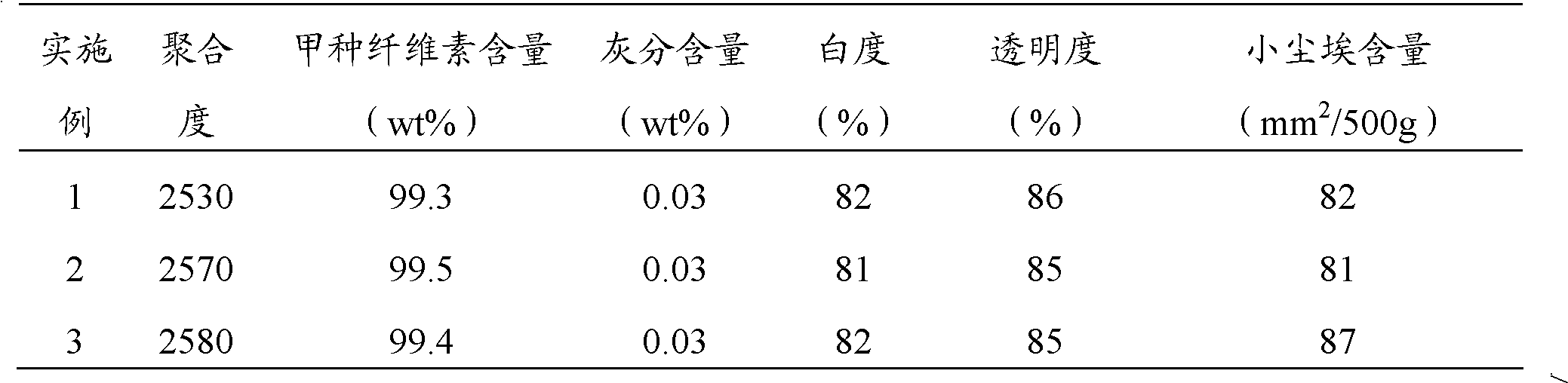

[0078] The quality of the obtained high-polymerization degree cotton pulp was tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com