Method for processing quality of sauced beef

A processing method and sauce beef technology, applied in climate change adaptation, food science and other directions, can solve the problems of vague process parameters, backward processing technology, simple production equipment, etc., to improve the yield and texture stability, and improve the product shelf. the effect of improving product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

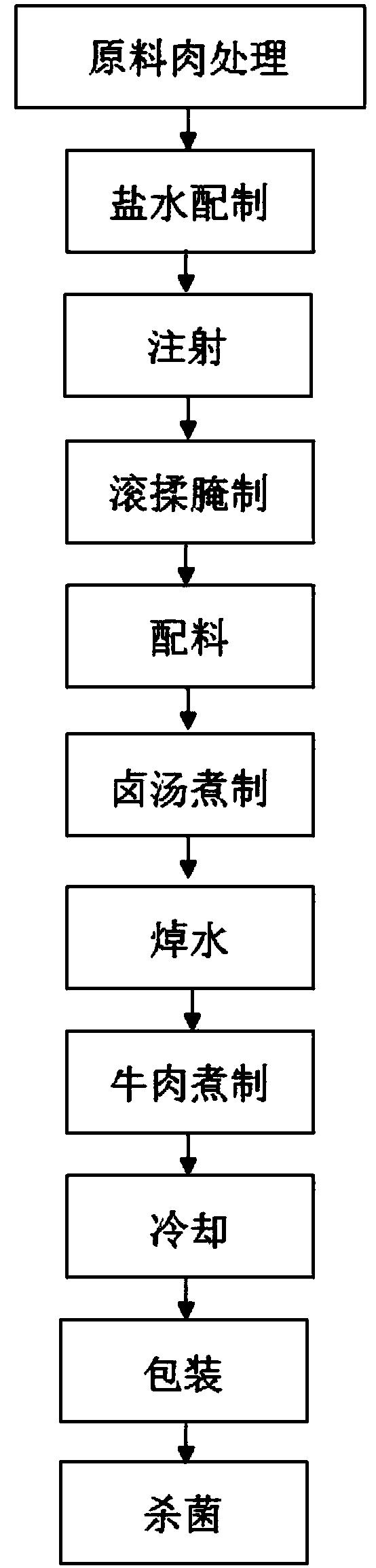

[0040] Such as figure 1 Shown, a kind of processing method that the present embodiment 1 provides improves the beef sauce quality, comprises the steps:

[0041] Step 1: Raw Meat Processing

[0042] Raw meat selection and trimming: remove fascia, tendon, cartilage, lymph, congestion, fat, dirt, etc., trim the raw meat into meat pieces of about 1kg, then rinse the blood stains on the surface with clean water, drain the water, 0-6°C Save it for later use. Before official use, the beef should be broken down into pieces of about 250-500g for use, which is convenient for marinating and flavoring.

[0043] Step 2: Salt water preparation

[0044] Add injection auxiliary materials into water, stir and mix evenly to obtain injection liquid, set aside, add water according to 20% of beef mass; said injection auxiliary materials include the following ingredients: tripolyphosphate, salt, nitrous, sodium lactate, TG and steamed fish Soy sauce; the injection auxiliary materials are added t...

Embodiment 2

[0064] Such as figure 1 As shown, a kind of processing method that the present embodiment 2 provides improves the quality of sauced beef, comprises the steps:

[0065] Step 1: Raw Meat Processing

[0066] Raw meat selection and trimming: remove fascia, tendon, cartilage, lymph, congestion, fat, dirt, etc., trim the raw meat into meat pieces of about 1kg, then rinse the blood stains on the surface with clean water, drain the water, 0-6°C Save it for later use. Before official use, the beef should be broken down into pieces of about 250-500g for use, which is convenient for marinating and flavoring.

[0067] Step 2: Salt water preparation

[0068] Add the auxiliary materials for injection into the water, stir and mix evenly to obtain the injection liquid, set aside, and add water according to 10-40% of the mass of beef; the auxiliary materials for injection include the following ingredients: tripolyphosphate, salt, nitrous, sodium lactate, TG and Steamed fish soy sauce; the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com