Concrete synergist and preparation method thereof

A technology of concrete synergist and methacrylic acid, which is applied in the field of building materials, can solve the problems of poor concrete encapsulation, slump loss over time, etc., and achieve the effects of improving efficacy, improving workability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

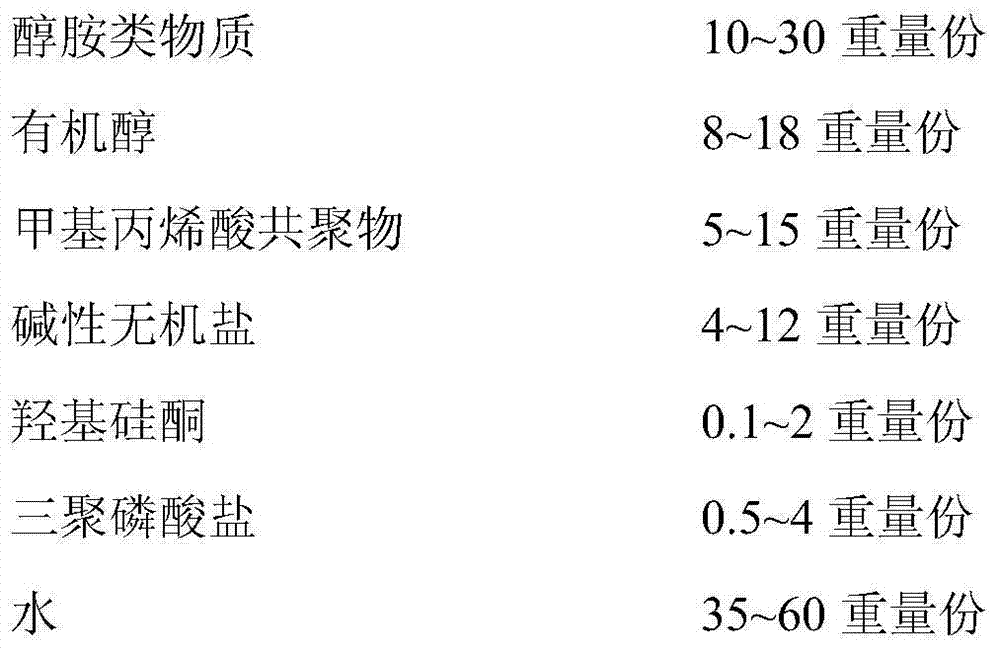

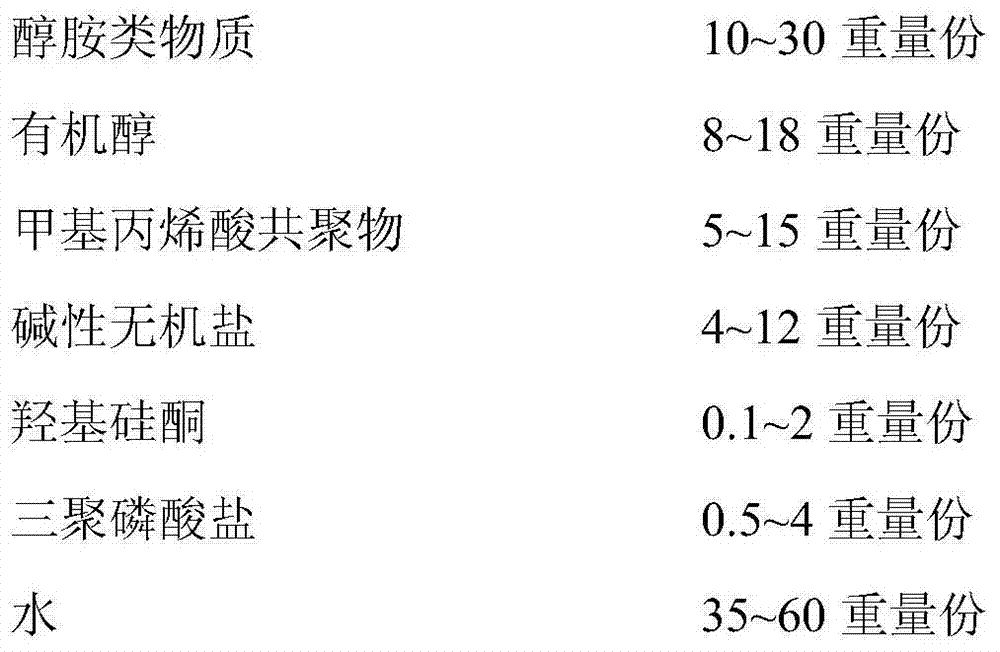

Method used

Image

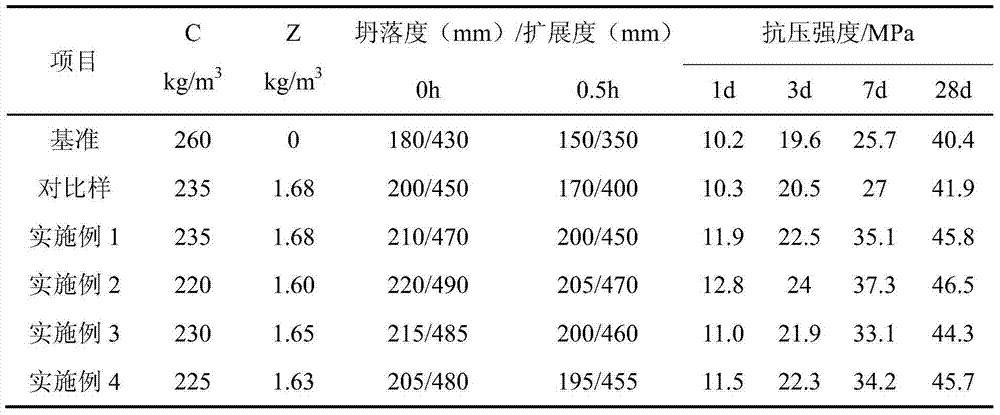

Examples

Embodiment 1

[0027] In parts by weight, take 20 parts of triisopropanolamine, 10 parts of diethylene glycol, 5 parts of glycerol, 4 parts of starch, co-MAA- 7 parts of HEA, 8 parts of sodium carbonate, 0.2 part of hydroxy silicone emulsion 6-PDMS with a degree of polymerization of 6, 2 parts of sodium tripolyphosphate, and 50 parts of water were sequentially added into the reaction bottle, and stirred at room temperature for 3 hours to obtain the finished product.

Embodiment 2

[0029] In parts by weight, take 15 parts of triisopropanolamine, 12 parts of triethanolamine, 8 parts of 1,2-octanediol, 4 parts of 1,2-propanediol, the molecular weight is 50000 and the block ratio is MAA:HEA is 3 : 5 parts of co-MAA-HEA of 1, 3 parts of co-MAA-EA, 6 parts of sodium carbonate, 4 parts of sodium silicate, 1 part of hydroxyl silicone emulsion 8-PDMS with a degree of polymerization of 8, 1 part of sodium tripolyphosphate 1 part, 1 part of potassium tripolyphosphate, and 40 parts of water were sequentially added into the reaction flask, and stirred at room temperature for 3 hours to obtain the finished product.

Embodiment 3

[0031] In parts by weight, take 15 parts of triisopropanolamine, 10 parts of diethylene glycol, 4 parts of glycerol, 4 parts of 1,2-octanediol, the molecular weight is 40000 and the block ratio is MAA:HPA is 4: 12 parts of co-MAA-HPA, 5 parts of sodium silicate, 1.5 parts of hydroxy silicone emulsion 8-PDMS with a degree of polymerization of 8, 3 parts of potassium tripolyphosphate, and 48 parts of water were sequentially added to the reaction bottle, and stirred at room temperature for 3 hours Afterwards, the finished product is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com