Method for regulating morphology of hydroxyapatite micro-nanomaterial by using phosphorus source

A technology for regulating hydroxyapatite and hydroxyapatite, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult to meet the practical application requirements of mass production, complex synthesis methods, etc. The effect of universality, simple operation method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

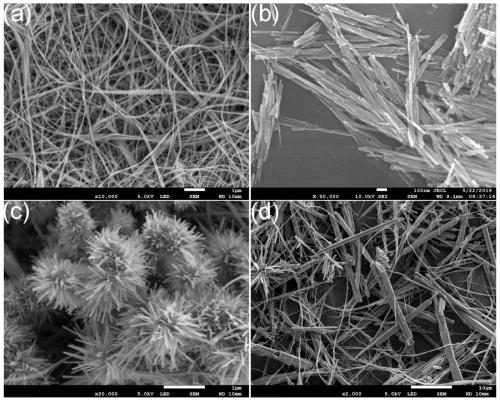

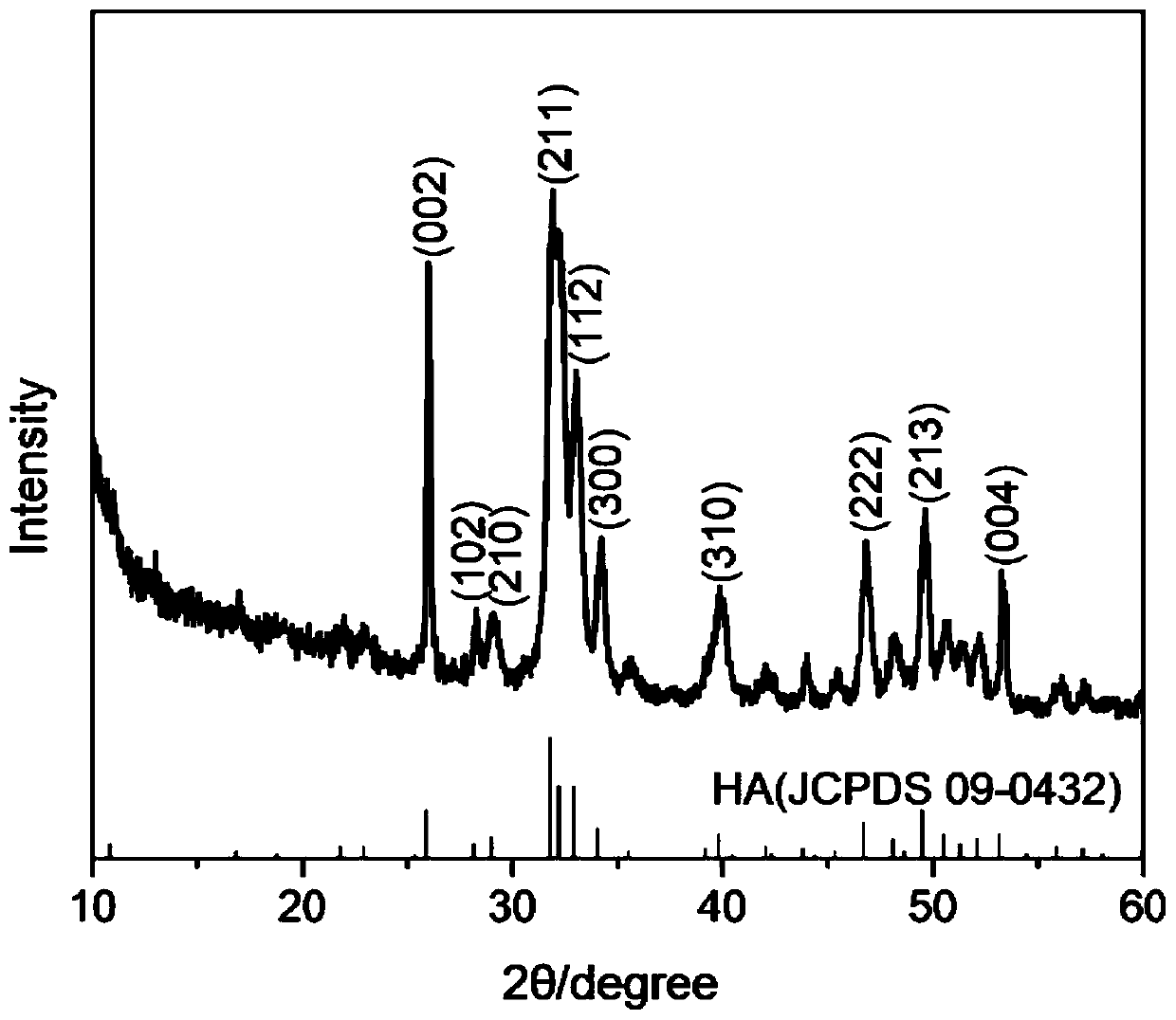

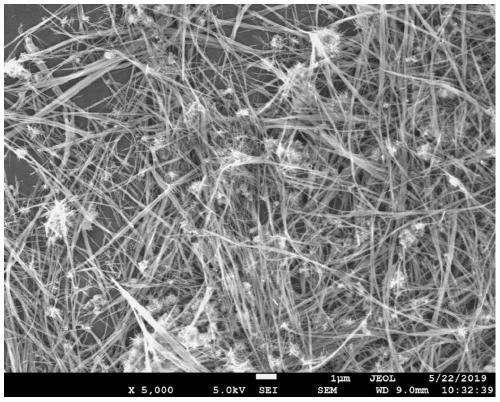

[0060] A method for regulating the morphology of hydroxyapatite micro-nano material by using a phosphorus source, mainly comprising the following steps:

[0061] In a water bath at 60°C, mix 6.00g of absolute ethanol and 6.00g of brown keto acid, and stir for 3min under magnetic stirring at 300r / min to mix the two evenly; An aqueous solution of calcium and 10 ml of an aqueous solution containing 0.50 g of sodium hydroxide form a saturated calcium palmitate precursor; under stirring conditions, add 5 ml of an aqueous solution containing 0.442 g of sodium phosphate dodecahydrate dropwise, and wait until the sodium phosphate dodecahydrate has been added dropwise After the aqueous solution, the reaction solution was transferred to a hydrothermal reaction kettle, heated to 180° C., and then solvothermally reacted for 5 hours. When the hydrothermal reaction kettle is cooled to room temperature with the furnace, the reaction product is transferred, washed alternately with alcohol and...

Embodiment 2

[0064] A method for regulating the morphology of hydroxyapatite micro-nano material by using a phosphorus source, mainly comprising the following steps:

[0065] In a water bath at 60°C, mix 6.00g of absolute ethanol and 6.00g of brown keto acid, and stir for 3min under magnetic stirring at 300r / min to mix the two evenly; The aqueous solution of calcium and 10ml containing the aqueous solution of 0.50g sodium hydroxide form the calcium palmitate precursor; Add dropwise the aqueous solution of 5ml containing 0.375g sodium trimetaphosphate under stirring condition, after treating that the aqueous solution of sodium trimetaphosphate is added dropwise, The reaction liquid was transferred to a hydrothermal reaction kettle, heated to 180° C., and then reacted by solvothermal reaction for 5 h. When the hydrothermal reaction kettle is cooled to room temperature with the furnace, the reaction product is transferred, washed alternately with alcohol and deionized water for several times,...

Embodiment 3

[0068] A method for regulating the morphology of hydroxyapatite micro-nano material by using a phosphorus source, mainly comprising the following steps:

[0069] In a water bath at 60°C, mix 6.00g of absolute ethanol and 6.00g of brown keto acid, and stir for 3min under magnetic stirring at 300r / min to mix the two evenly; The aqueous solution of calcium and 10ml containing the aqueous solution of 0.50g sodium hydroxide form the calcium palmitate precursor; Add dropwise the aqueous solution of 5ml containing 0.143g sodium tripolyphosphate under stirring condition, after treating that the aqueous solution of sodium tripolyphosphate is added dropwise, The reaction liquid was transferred to a hydrothermal reaction kettle, heated to 180° C., and then reacted by solvothermal reaction for 5 h. When the hydrothermal reaction kettle was cooled to room temperature with the furnace, the reaction product was transferred, washed alternately with alcohol and deionized water for several time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com