Novel membrane cleaning agent

A technology of membrane cleaning agent and cleaning agent, which is applied in the field of cleaning agents, can solve the problems of membrane material damage and poor cleaning effect, and achieve the effect of reducing fouling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Prepare 1000kg of the present invention

[0019] (1) Weigh 120kg of tripolyphosphate and 250kg of EDTA (ethylenediaminetetraacetic acid) into a homogenizer or homogenizer and stir evenly;

[0020] (2) Put the uniformly stirred material into the heating equipment, and then add 410kg of sodium dodecylbenzenesulfonate to it to stir the material evenly; then, heat up and control the temperature at 75-80°C to react and solidify ;

[0021] (3) After the above solidified material is cooled, add 100kg of alkylaryl polyether alcohol and 120kg of protease, and crush it in a crushing device to make a solid powder product.

Embodiment 2

[0023] Prepare 2500kg of the present invention

[0024] (1) Weigh 500kg of sodium hexametaphosphate and 620kg of NTA (aminotriacetic acid) into a homogenizer or homogenizer and stir evenly;

[0025] (2) Put the uniformly stirred material into the heating equipment, and then add 805kg Tween 20 to it to stir the material evenly; then, heat up and control the temperature at 75-80°C to react and solidify;

[0026] (3) After the above solidified material is cooled, add 375kg of modified polyether and 200kg of KAC, and crush it in a crushing device to make a solid powder product.

PUM

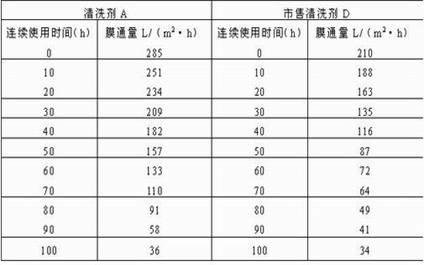

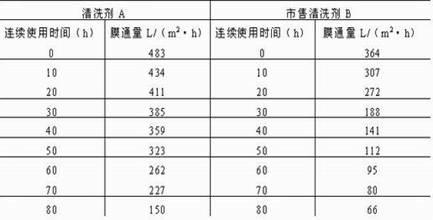

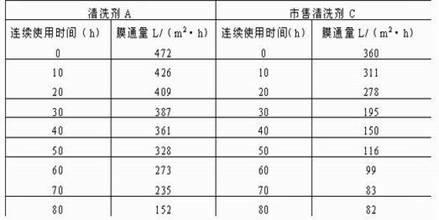

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com