A pumpless flushing upflow filter and its water filtration method

A filter tank and water filtration technology, applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve the problem that the filter material is not fully utilized, the operation and maintenance costs are high, and the overall equipment occupies a large area. and other problems, to achieve the effect of improving the filtration effect, reducing the burden of operation and maintenance, reducing investment and equipment land consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and examples. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

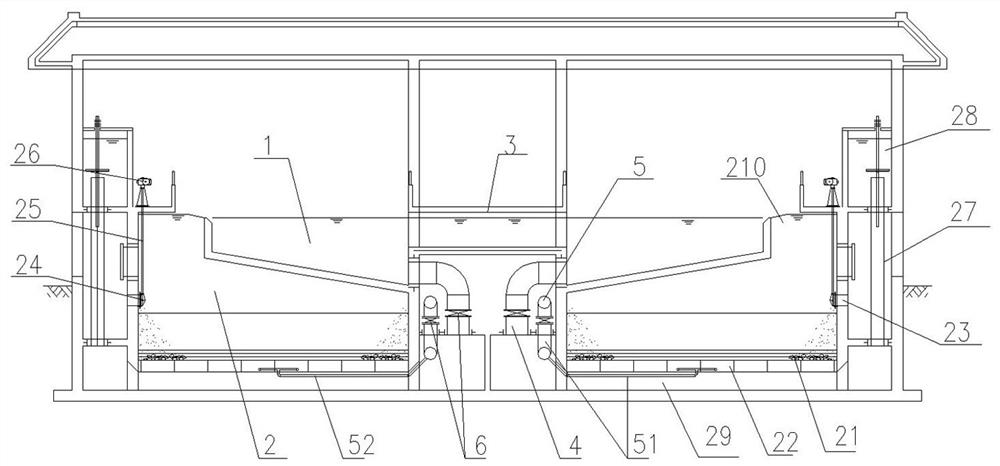

[0033] Such as figure 1 As shown, a non-pump rinsing the upper flow filter, the filter includes a plurality of filtration units, and the filter unit consists of a cleaning warehouse 1 and a plurality of parallel filtraminated filter bonds, and there is a two adjacent filter unit. Observe the road, observe the road 3 and the clean water warehouse 1 contour setting.

[0034] The clean water warehouse 1 is disposed above the filter boy 2, and the cleaning bin 1 is provided with a flush tube 4 at the bottom of each filter boy, and the top of the filter boon 2 is provided with the clear water overflow port 210 in commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com