Filter element for water filter treatment

A technology of water filtration and filter elements, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ultrafiltration, etc., can solve problems such as blockage of filter elements or filter media, increase in waste volume, waste of resources, etc., and achieve recovery Filtration function, reduction of waste amount, and effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

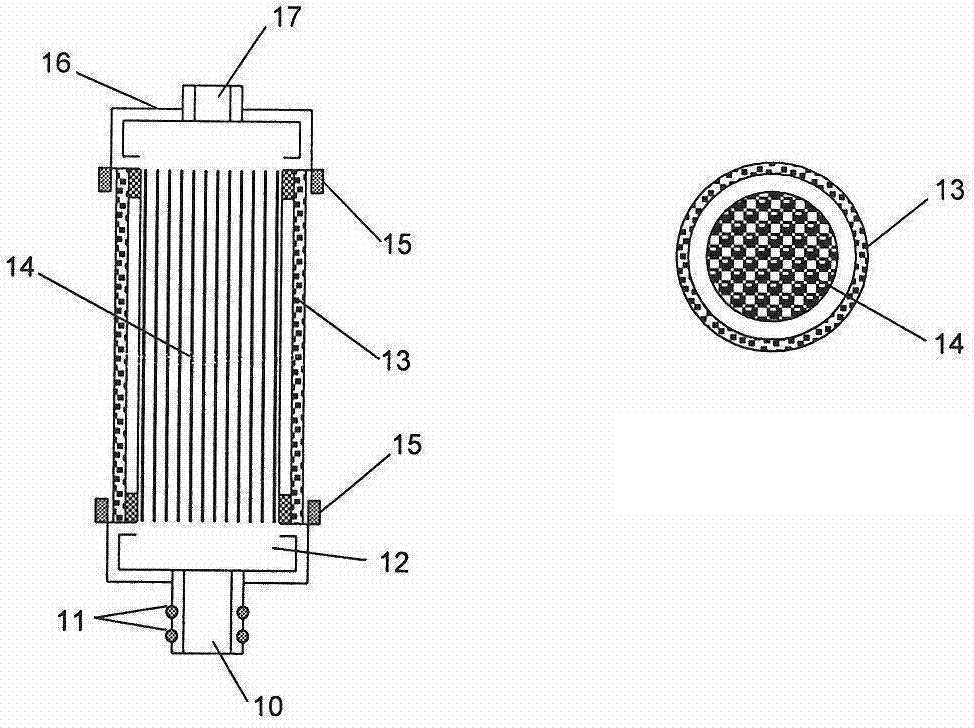

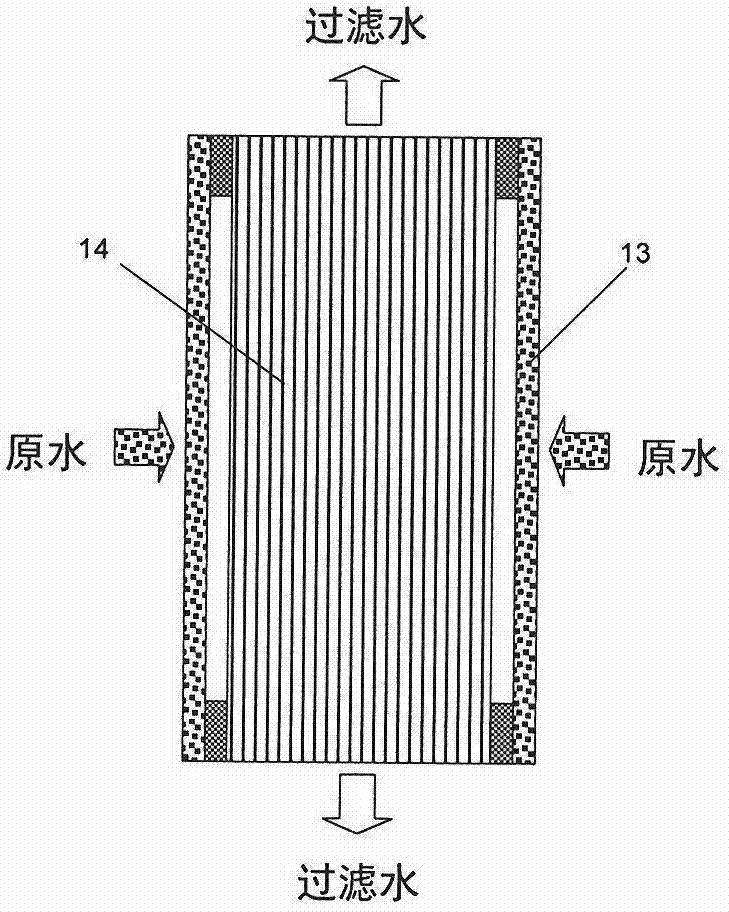

[0015] Such as figure 1 As shown, the working principle of the filter element for water filtration treatment of the present invention is that the raw water (filtered water) passes through the inner and outer double-layer filtration structure: firstly filtered by the sheet-type filter membrane 13 on the outer layer of the filter element, and then through the outer layer covered The inner layer and the outer pressure type hollow fiber ultrafiltration membrane 14 filter. The sheet-type filter membrane is covered on the outside of the external pressure hollow fiber ultrafiltration membrane. The outer membrane constitutes the first filtration of the filter element, and the inner membrane constitutes the second filtration. In this way, the pollutants in the raw water are firstly filtered and removed by the outer membrane, and the filtered pollutants adhere t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com