Coal gasification wastewater treatment method

A treatment method, waste water technology, applied in water/sewage treatment, natural water body treatment, chemical instruments and methods, etc., can solve problems such as high COD value, reduce the economic efficiency of coal gasification process, and fail to meet environmental protection emissions, etc., to achieve reduction Wastewater treatment cost, save wastewater treatment process, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

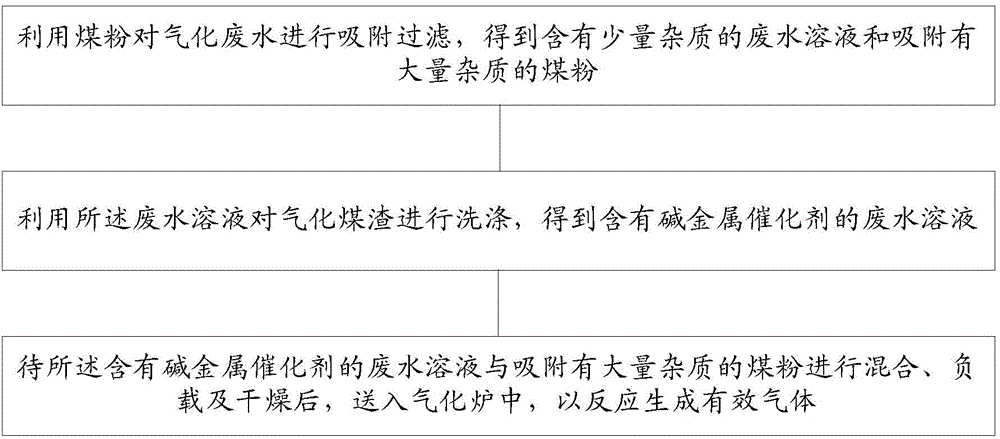

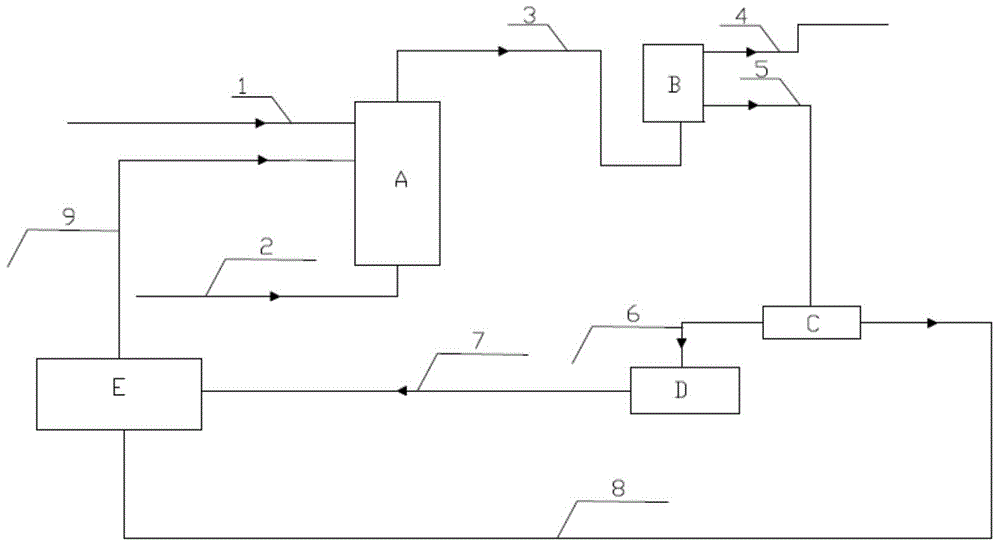

Method used

Image

Examples

Embodiment 1

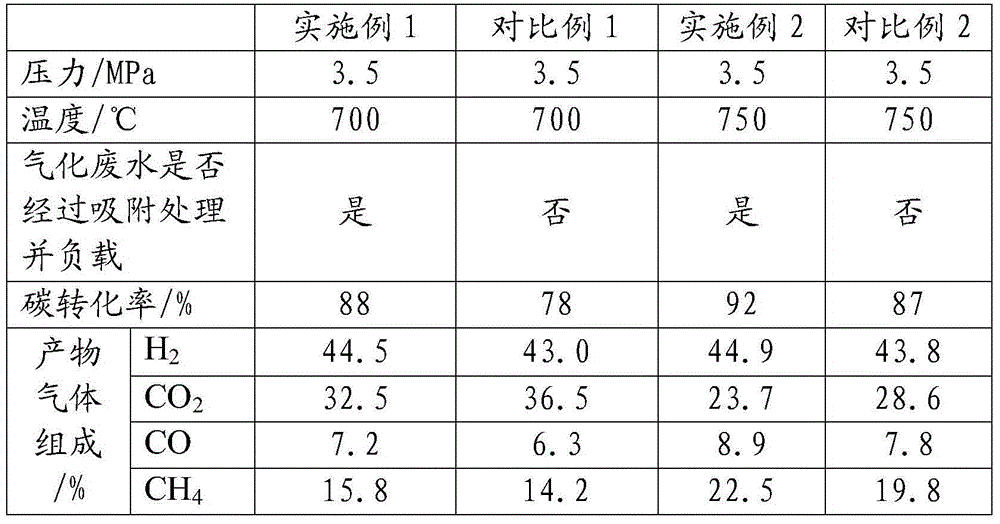

[0050] The raw coal a absorbs the tar and phenol ammonia in the gasification wastewater, and then loads it with the alkali metal catalyst recovered from the wastewater, and then enters the gasifier for gasification. The process conditions are 3.5Mpa and 700°C. The experimental results show that the carbon conversion rate is 88%, the gas composition is: H 2 : 44.5%, CO 2 : 32.5%, CO: 7.2%, CH 4 : 15.8%.

Embodiment 2

[0054] The raw coal a absorbs the tar and phenol ammonia in the gasification wastewater, and then loads it with the alkali metal catalyst recovered from the wastewater, and then enters the gasifier for gasification. The process conditions are 3.5Mpa and 750°C. The experimental results show that the carbon conversion rate 92%, the gas composition is: H 2 : 44.9%, CO 2 : 23.7%, CO: 8.9%, CH 4 : 22.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com