Preparation method of modified polypropylene oil-water separation membrane and modified polypropylene oil-water separation membrane prepared by preparation method

A technology of oil-water separation membrane and polypropylene membrane, which is applied in the field of membrane materials, can solve the problems of low oil-water separation efficiency, poor mechanical properties, and easy pollution of the membrane, and achieve high oil-water separation efficiency, high oil-water separation efficiency, and increased hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a modified polypropylene oil-water separation membrane material, the specific steps are as follows:

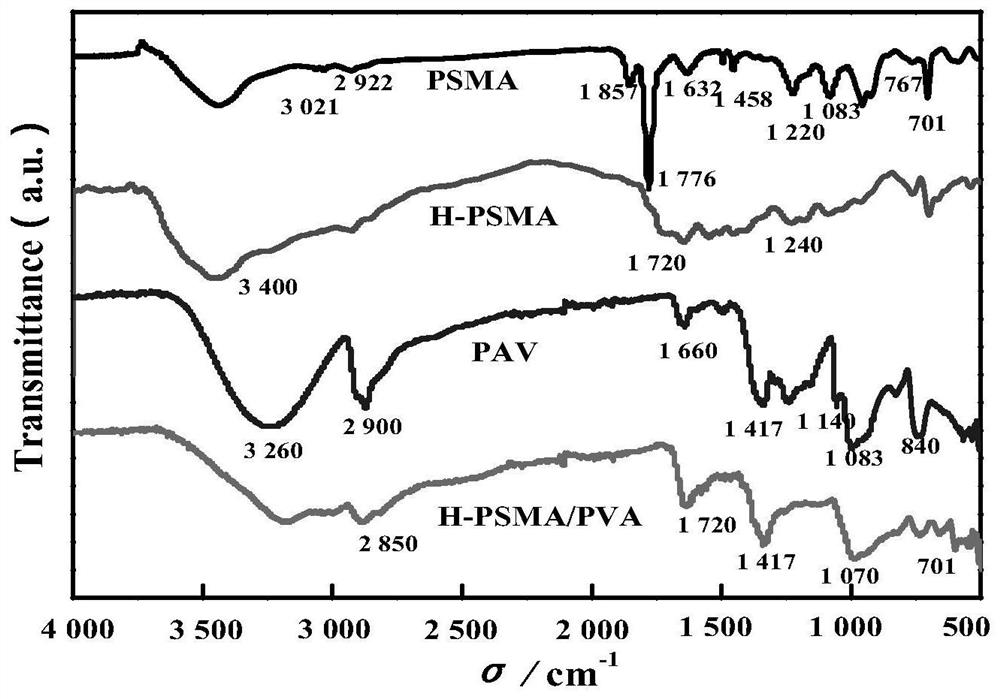

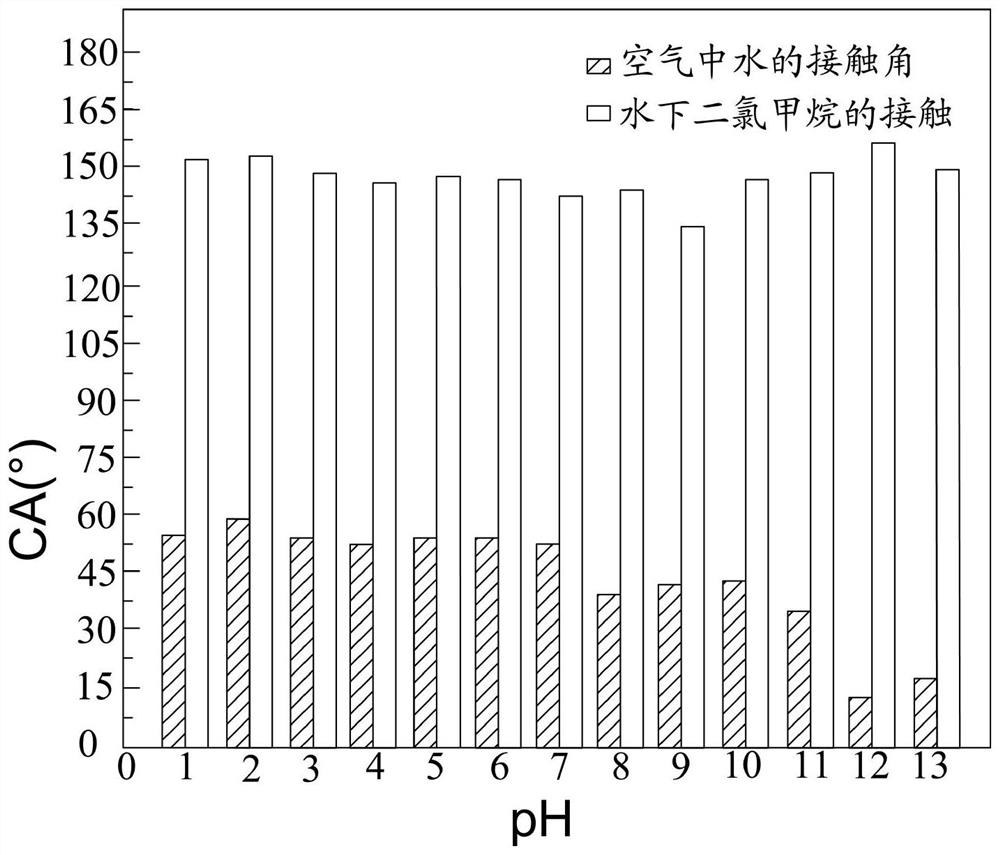

[0032] (1) Put 2g of PSMA and 100ml of water into a three-necked flask, add 6ml of ammonia water, stir and hydrolyze at 50°C, until the hydrolysis is complete, the system becomes a colorless and transparent solution, add a few drops of sulfuric acid solution to neutralize, cool to room temperature, and filter with suction A solid product was obtained, which was washed twice with deionized water and dried at 50° C. for 24 hours to obtain H-PSMA.

[0033] (2) Take 1g of H-PSMA and 0.6g of PVA in 15ml of deionized water, dissolve it at 90°C for 1h to make it completely dissolved, cool to room temperature, take commercially available 50% glutaraldehyde aqueous solution (according to the molar ratio of hydroxyl and aldehyde groups) Dilute to 5ml at 1:0.5, add to the above solution, and stir at room temperature to obtain H-PSMA / PVA modified solution. ...

Embodiment 2

[0036] A kind of preparation method of modified polypropylene oil-water separation membrane, concrete steps are as follows:

[0037] (1) Take 2g of PSMA in 100ml of deionized water, add 6ml of ammonia water, stir and hydrolyze at 50°C, until the hydrolysis is complete, the system becomes a colorless transparent solution, add a few drops of sulfuric acid solution to neutralize, cool to room temperature, and filter to obtain a solid product , the solid product was washed twice with deionized water, and dried at 50°C for 24 hours to obtain H-PSMA.

[0038] (2) Take 1g H-PSMA and 0.2g PVA in 15ml deionized water, dissolve it at 90°C for 1 hour to make it completely dissolved, cool to room temperature, take commercially available 50% glutaraldehyde aqueous solution (the molar ratio of hydroxyl and aldehyde groups is 1:0.3) was diluted to 5ml, added to the above solution, and stirred at room temperature to obtain a cross-linked H-PSMA / PVA modified solution.

[0039] (3) Soak the po...

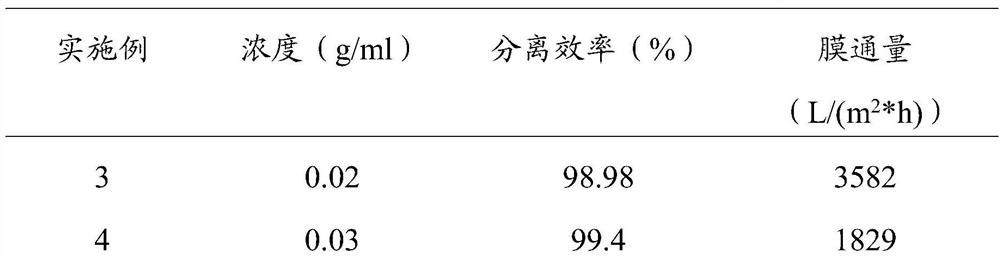

Embodiment 3

[0041] A kind of preparation method of modified polypropylene oil-water separation membrane, concrete steps are as follows:

[0042] (1) Add 2g of PSMA to 100ml of deionized water, add 6ml of ammonia water, stir and hydrolyze at 50°C, wait until the hydrolysis is complete, the system becomes a colorless transparent solution, add a few drops of sulfuric acid solution to neutralize, cool to room temperature, and obtain a solid product by suction filtration , the solid product was washed twice with deionized water, and dried at 50°C for 24 hours to obtain H-PSMA.

[0043](2) Take 1g of H-PSMA and 1g of PVA in deionized water, dissolve it at 90°C for 1h to dissolve completely, cool to room temperature, take commercially available 50% glutaraldehyde aqueous solution (according to the molar ratio of hydroxyl and aldehyde groups is 1: 0.2), added to the above solution to make the modified solution concentration 0.02g / ml, stirring at room temperature.

[0044] (3) Soak the polypropyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com