Oil well acidification produced liquid dehydration method

A technology for oil well acidification and produced fluid, applied in the direction of chemical dehydration/demulsification, etc., can solve the problem of increasing the difficulty of demulsification of produced fluid, and achieve the effect of good oil-water separation effect, low water content, and fast dehydration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

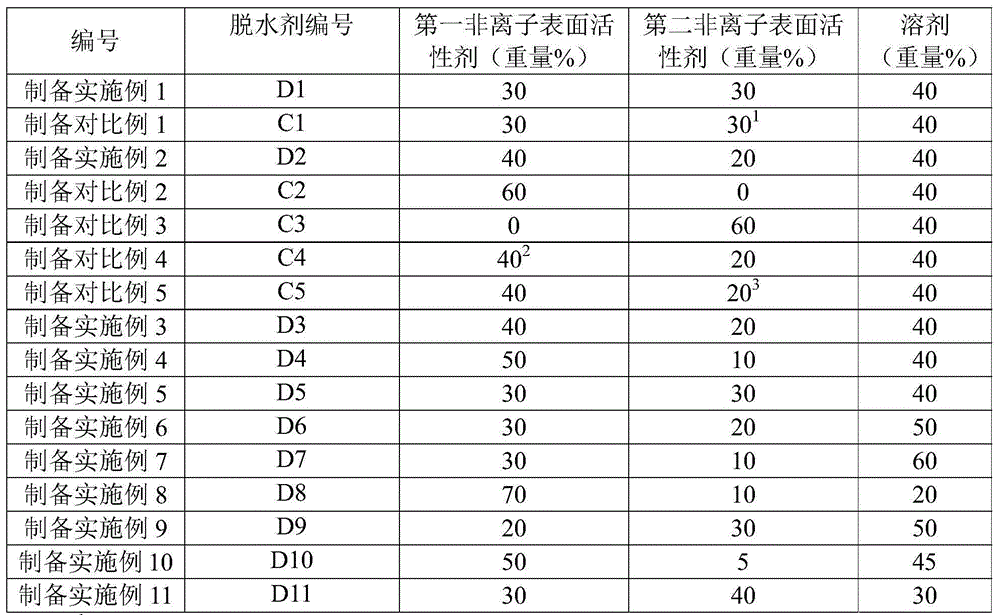

[0047] (1) According to the composition of Table 1, the polyoxyethylene-polyoxypropylene block copolymer type nonionic surfactant (purchased from Binhua Group, the brand is AE10071), line Alkylphenol polyoxyethylene ether type nonionic surfactant (purchased from Binhua Group, brand name NP15) and water were mixed evenly to obtain the dehydrating agent according to the present invention, denoted as D1.

preparation Embodiment 2

[0051] According to the composition of Table 1, the polyoxyethylene-polyoxypropylene block copolymer type nonionic surfactant (purchased from Binhua Group, brand TA1031) with phenolamine resin as the initiator, polyether grafted poly Dimethylsiloxane type nonionic surfactant (purchased from Yinuoen Chemical Co., Ltd., brand YNE5211) and solvent (a mixture of ethanol and water, wherein the weight ratio of ethanol and water is 1:2) mixed Uniformly, thus obtain the dehydrating agent according to the present invention, denoted as D2.

preparation Embodiment 3

[0061] The same method as Preparation Example 2 was used to prepare the dehydrating agent, the difference was that the polyether grafted polydimethylsiloxane type nonionic surfactant used an equivalent amount of alkylphenol polyoxyethylene ether (purchased from Binhua Group, trade mark is NP15) instead, thereby obtains dehydrating agent, is recorded as D3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com