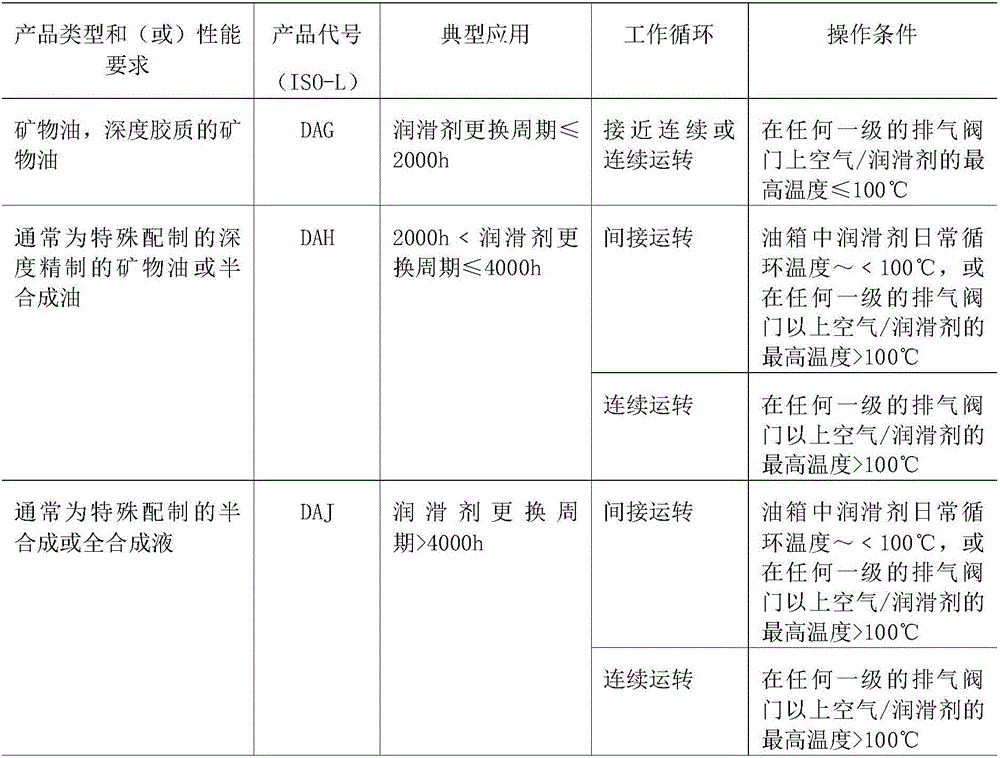

Totally-synthesized DAJ heavy-load screw air compressor oil composition

An air compressor oil and composition technology, applied in the field of lubricating oil, can solve the problems of poor anti-emulsification performance, shortened service life, long oil-water separation time, etc., and achieve good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

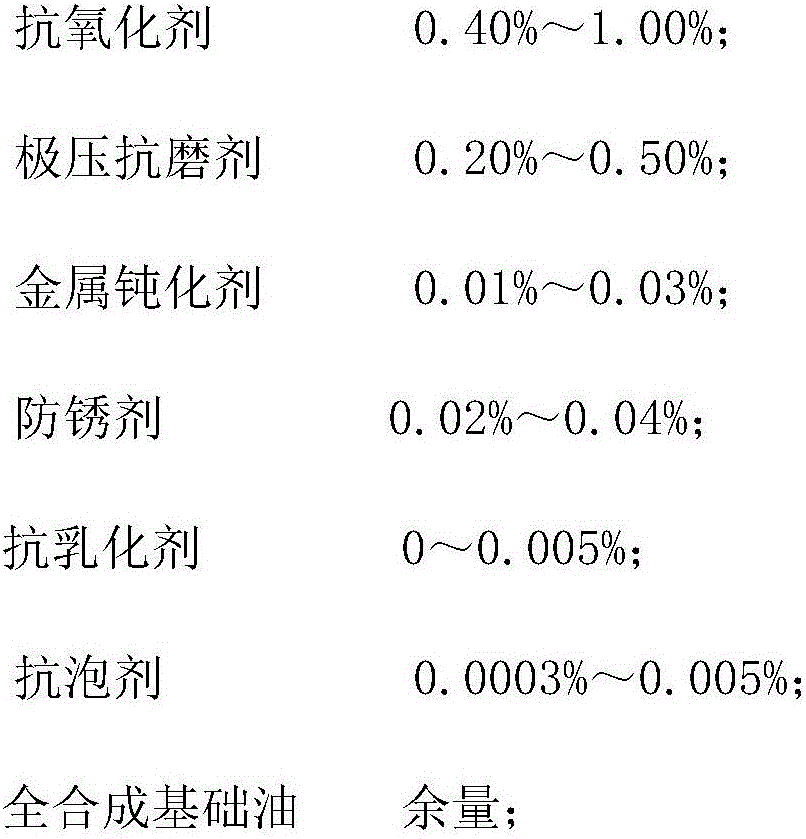

Method used

Image

Examples

Embodiment 1

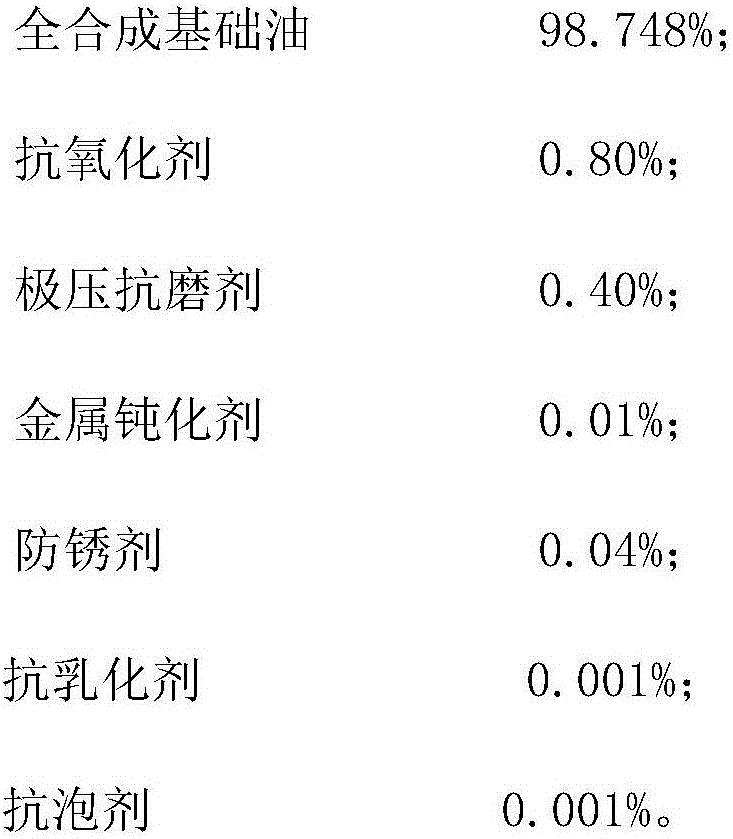

[0042] Embodiment 1: 32 fully synthetic DAJ heavy-duty screw air compressor oil compositions

[0043] In a 5000mL stainless steel barrel, weigh 2000g according to the following ratio (mass fraction); the functional additive is accurate to 0.1g: 1. Fully synthetic base oil composition

[0044] (1) Alkyl naphthalene 8%

[0045] (2) Balance of polyalphaolefin (PAO)

[0046] 2. Functional additive composition

[0047] Antioxidant Additive Composition

[0048] Amine type high temperature antioxidant additive composition:

[0049] (1) C4 / C8 alkyl substituted diphenylamine 0.20%

[0050] (2) Phenyl-α-naphthylamine 0.25%

[0051] Phenolic antioxidant additives:

[0052] 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid 2-ethyl-hexyl ester 0.15%

[0053] Antioxidant and antiwear multi-effect additives:

[0054] Methyl di-n-butyldithiocarbamate 0.20%

[0055] Extreme pressure antiwear additive composition:

[0056] (1) Tricresyl phosphate 0.27%

[0057] (2) Phosphorodithioate 0...

Embodiment 2

[0070] Embodiment 2: 32 fully synthetic DAJ heavy-duty screw air compressor oil compositions

[0071] In a 5000mL stainless steel barrel, weigh 2000g according to the following ratio (mass fraction), and the functional additive is accurate to 0.1g: 1. Fully synthetic base oil composition

[0072] (1) Neopentyl polyol ester 5%

[0073] (2) Balance of polyalphaolefin (PAO) 2. Functional additive composition

[0074] Antioxidant Additive Composition

[0075] Amine type high temperature antioxidant additive composition:

[0076] (1) C4 / C8 alkyl substituted diphenylamine 0.18%

[0077] (2) Phenyl-α-naphthylamine 0.25%

[0078] Phenolic antioxidant additives:

[0079] 2-ethyl-hexyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate 0.30%

[0080] Antioxidant and antiwear multi-effect additives:

[0081] Methyl di-n-butyldithiocarbamate 0.25%

[0082] Extreme pressure antiwear additive composition:

[0083] (1) Tricresyl phosphate 0.30%

[0084] (2) Phosphorodithioate 0.20%; metal...

Embodiment 3

[0094] Embodiment 3: 46 fully synthetic DAJ heavy-duty screw air compressor oil compositions

[0095] In a 5000mL stainless steel barrel, weigh 2000g according to the following ratio (mass fraction), and the functional additive is accurate to 0.1g:

[0096] 1. Fully synthetic base oil composition

[0097] (1) Neopentyl polyol ester 4%

[0098] (2) Polyether balance

[0099] 2. Functional additive composition:

[0100] Antioxidant Additive Composition

[0101] Amine type high temperature antioxidant additives:

[0102] (1) C4 / C8 alkyl substituted diphenylamine 0.23%

[0103] (2) Phenyl-α-naphthylamine 0.29%

[0104] Phenolic antioxidant additives:

[0105] 2-ethyl-hexyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate 0.25%

[0106] Antioxidant and antiwear multi-effect additives:

[0107] Methyl di-n-butyldithiocarbamate 0.30%

[0108] Extreme pressure antiwear additive composition:

[0109] (1) Tricresyl phosphate 0.27%

[0110] (2) Phosphorodithioate 0.21%;

[0111] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com