Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

A super-heavy oil and composite technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high quality of heavy oil, poor high temperature resistance, large amount of viscosity reducer, etc., and achieve environmental protection effect Good, good high temperature resistance, low viscosity and frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

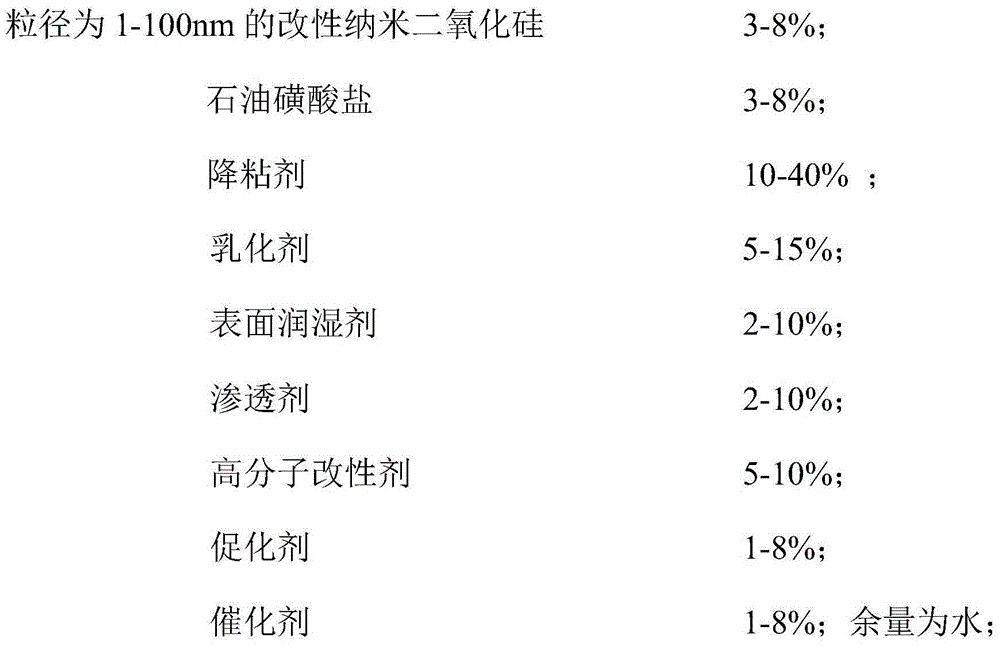

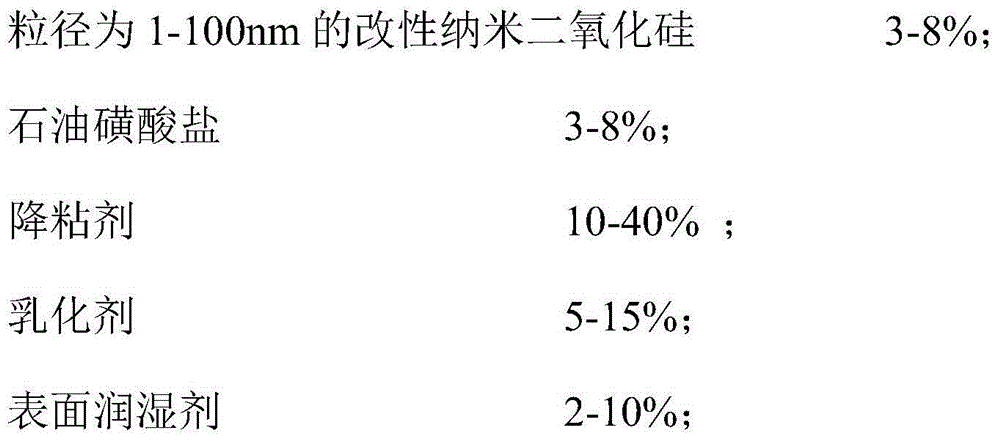

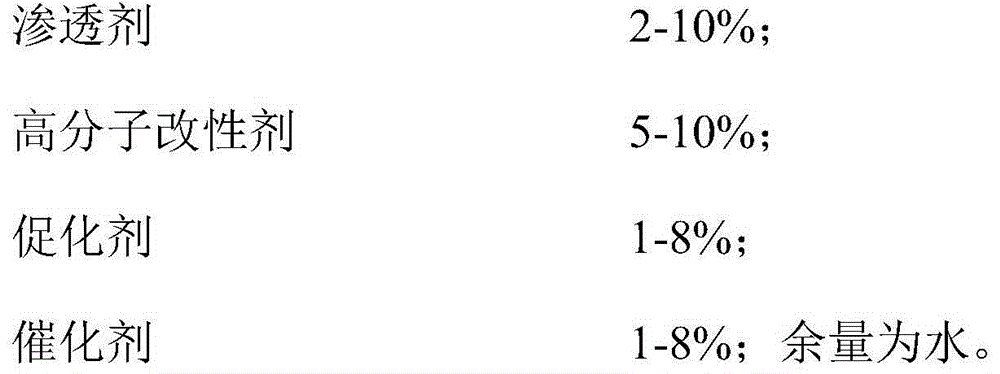

Method used

Image

Examples

Embodiment 1

[0044] Petroleum sulfonate 6.0g, fatty alcohol polyoxyethylene ether phosphate 10.0g, isooctylphenol polyoxyethylene ether 8.0g, lignosulfonate 20.0g, sulfite 3.0g, monoethanolamine 3.0g Polymerize at 90°C in a mixer with a stirring device for 4 hours, then add 4.0g of modified nano-silica and mix for 1 hour, and finally add emulsifier TX-1010.0g, pull-off powder 6.0g, butadiene Add 8.0 g of dioctyl sodium di-sec-octyl sulfonate, 6.0 g of polyvinyl alcohol, add water to 100 g, and stir at room temperature for 1 hour to prepare a nano-composite high-temperature-resistant recovery aid for heavy oil and super heavy oil.

Embodiment 2

[0046] Petroleum sulfonate 6.0g, fatty alcohol polyoxyethylene ether phosphate 4.0g, polyethylene glycol octylphenyl ether 5.0g, lignosulfonate 10.0g, polyamine salt 4.0g, monoethanolamine 4.0g Polymerize in a mixer with a stirring device at 80°C for 6 hours, then add 4.0 g of modified nano-silica and mix for 1 hour, then add emulsifier AEO-98.0 g, pull-off powder 8.0 g, butadiene Di-sec-octyl enedioic acid sodium sulfonate 8.0g, polyethylene glycol 60006.0g, add water to 100g, stir at room temperature for 2 hours, and prepare heavy oil and super heavy oil using nano-composite high-temperature resistant recovery aids.

Embodiment 3

[0048] Put 5.0g of petroleum sulfonate, 7.0g of fatty alcohol polyoxyethylene ether phosphate ester salt, 10.0g of isooctylphenol polyoxyethylene ether, 21.0g of lignosulfonate, 3.0g of sulfate, and 3.0g of triethanolamine in Polymerize in a mixer with a stirring device for 3 hours at 95°C, then add 6.0 g of modified nano-silica and mix for 1.5 hours, and finally add emulsifier TX-10 10.0 g, Span-80 6.0 g, butene di Di-sec-octyl sodium sulfonate 10.0g, sorbitol 3.0g, add water to 100g, stir at room temperature for 1 hour, and prepare heavy oil and super heavy oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com